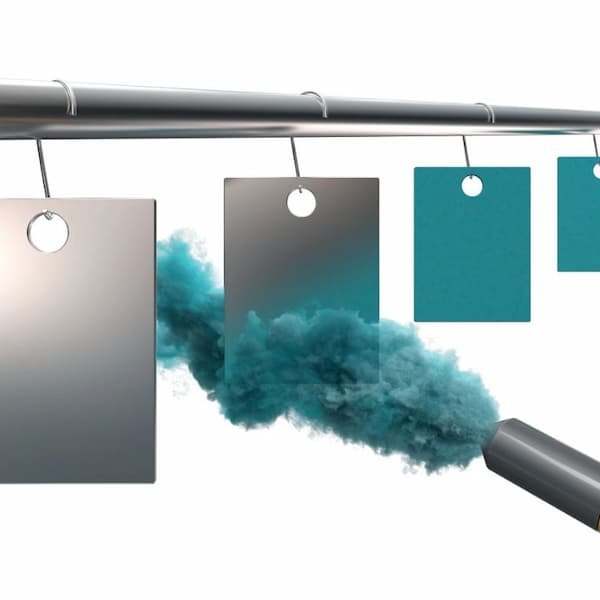

What is powder coating ?

Powder coating is becoming so popular for a number of reasons but how many people do not know what powder coating actually is. In this blog we give an insight into what powder coating is and some of the advantages of using this method of covering.