How are 3D printed parts used in real life applications

Using 3D printed parts as prototypes is ideal. However, it is an entirely different story having them in real life everyday applications.

Here are a couple of examples of igus® 3D printed parts being used in real life applications.

“To the rescue”- a spare part made in a 3D printer!

A customer recently contacted igus® to see if we could help.

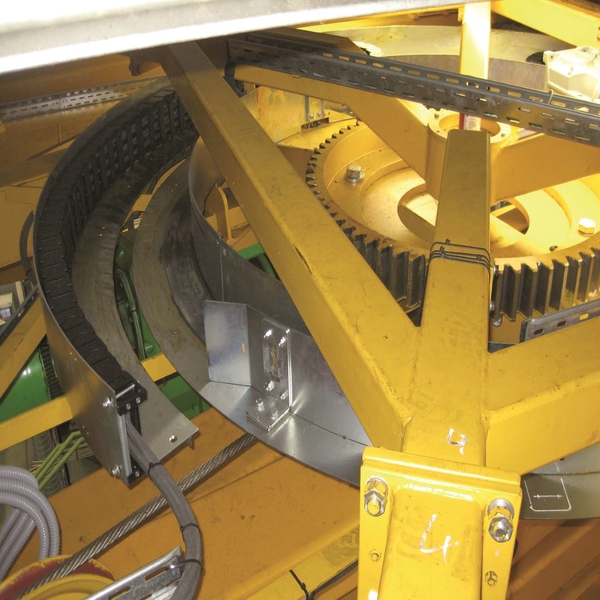

In one of their tractors the engine refused to start. It was established that a defective gear was responsible. The part needing to be replaced was damaged and therefore was not able to be scanned. So, an attempt was made to trace the broken spare part. And this was successful! The drawing was uploaded to the printing service as a STP file and iglidur® I6 was picked as the best material. This material has been especially developed for gears so it was the best material for the job. The printed component was ready within a few hours! Once again, the tractor was able to run perfectly!

Upgrade your pushchair with igus® 3D printed parts

Have you ever filled the car, ready for a weekend away with the children and realised that the pushchair will no longer fit? Luckily, nowadays the developers of the pushchair manufacturers designed pushchairs with removable tires. However this can cause an unpleasant surprise in the form of lubricated pins. In the best-case scenario, the lubricating oil only sticks to the hands, in the worst case to your clothes. So, first thought: Does that have to be lubricated? Tom Krause, Head of Additive Manufacturing, got to the bottom of the matter and clarified it. Check it out for yourself in this video.

Piano parts 3d Printed in iglidur® plastic

When Phoenix Piano contacted igus® they were looking for an innovative material that met the requirements for upgrading he grand piano. They found igus®. Manufacturing the individual plastic parts in small amounts was no problem. By printing the plastic parts in 3D, the required amount of the suitable iglidur® filament could be delivered very quickly. The “D3D hammer system” was born. This system has all the advantages of the traditional system. The designers at Phoenix even expect the new system to have a longer service life for the grand piano as unwanted side effects are a thing of the past. The simple change from wood to plastic significantly reduced sensitivity to moisture and temperature. As a result, the ivory coloured components are very similar to the original material and go perfectly with the rest of the design concept.

3D printing for the automotive industry

A recent example of 3d printing for the automotive industry is the co-operation project OptiAMix, in which igus® participates in addition to other partners from research and development. The project is about developing an adjustable rear spoiler that supports the motor vehicle’s driving dynamics with different adjustments, depending on the situation.

One significant advantage of 3D printing is the great design freedom when designing the parts. Complicated geometries can be quickly identified, with design modifications carried out “overnight”. This results in a large potential for lightweight technology and supports efficient design and the reduction of vehicle emissions.

This is precisely what makes 3D printed parts so attractive for design engineers in the automotive industry. With igus® you can produce parts in 3d printed materials easily with no minimum order quantity. Furthermore, there is a large variety of materials that can be used with wear parts printed in 3D.

Automatic cup table adjustment for fully automatic coffee machines

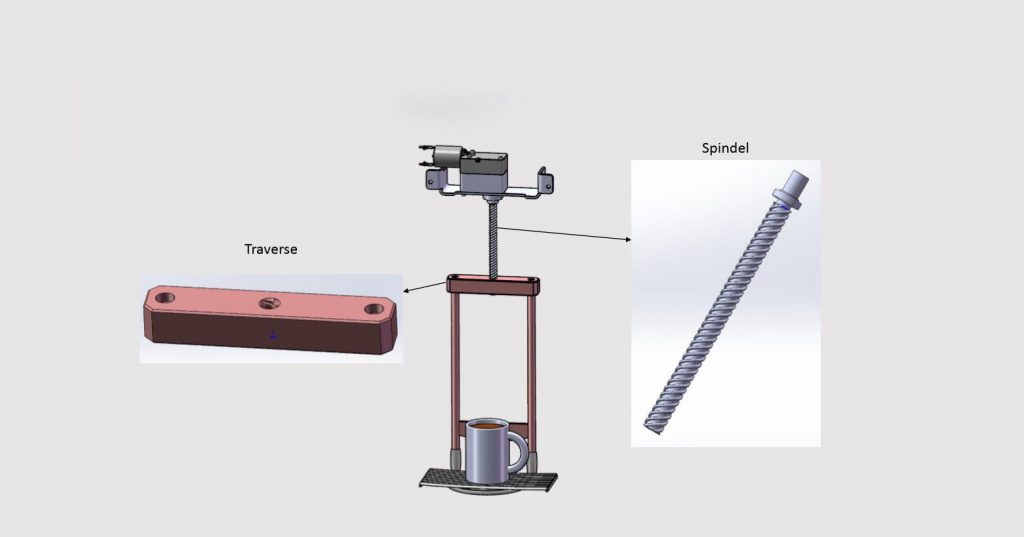

igus®‘ task was to develop a concept for a motorized cup table with sensor-controlled height adjustment.

The plan was to make this motion motorised as apposed to by hand. The sensors should detect the height of transparent and opaque cups and the motor should be controlled with the help of software until the specified distance is reached.

Our solution was is to drive the system by a motor with a 3D-printed spindle. After revising and improving the concept, we commissioned the 3D printing service for all components of the “crossbeam – spindle” concept.

Read more blogs about 3D printing here.