How do you decide on the best shaft material?

Shaft material, how do you decide? When considering the best partnership for your bearings, shaft and housing materials, what parameters do you think of? Do you consider what causes the wear in the shaft? Do you fully understand the potential consequences of not creating the best combination? Getting the fundamentals right from the offset could save you time, money and stress. It is all about ensuring that the relationships between your chosen materials work in harmony.

Causes of shaft wear and corrosion

The main cause for the premature demise of machines and systems and especially their bearings is incorrect lubrication and maintenance. Noticed too late, there is a risk of shaft and other important elements wearing out. Here, for example, expensive re-lubrication systems or maintenance-free slide bearings can help. Switching to maintenance-free plain bearings is easy. The bearings are inexpensive to procure and can be exchanged quickly. The range of plain bearing materials is huge and seems to have the right solution for every situation – from low friction, high load, broad temperature range requirements to exotic material specifications, the spectrum is endless.

The importance of the best combination

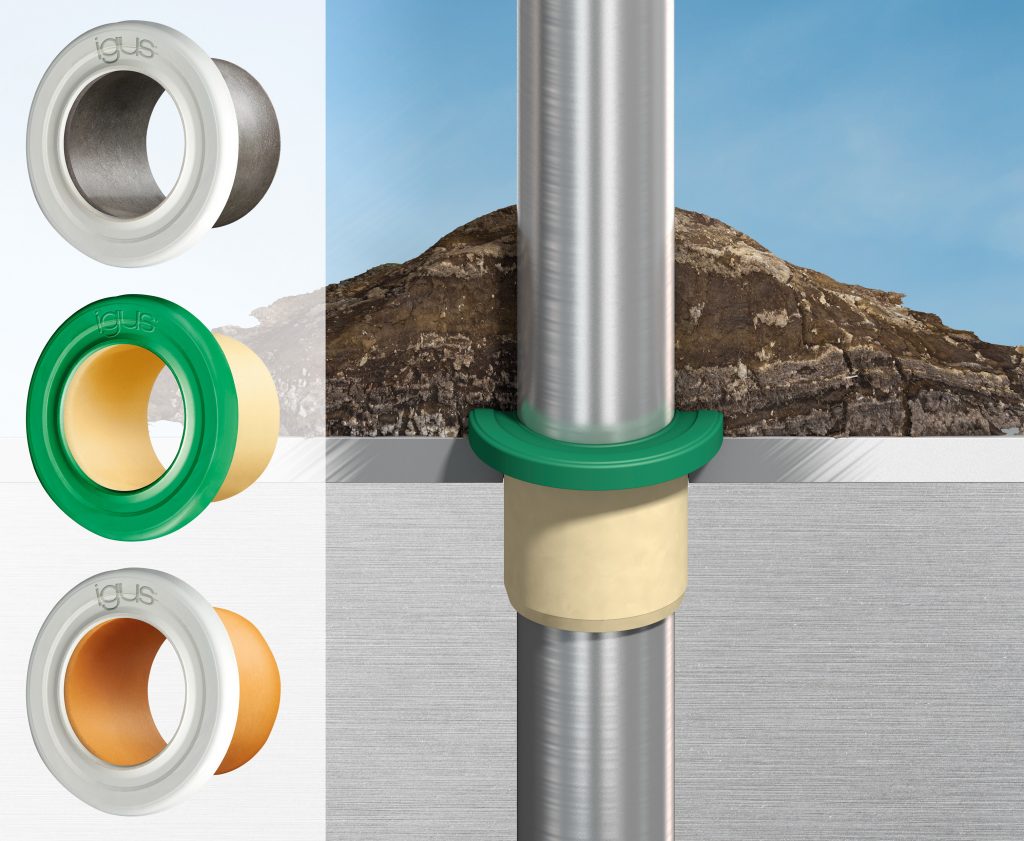

It is a fact that, in addition to parameters such as load and speed of rotation, the surface quality and condition of the shafts running in the plain bearings can influence the service life of the bearing. Just as there is an almost infinite number of different plain bearing solutions, there is also a wide variety of shaft materials, some of which are often unsuitable. In fact, depending on the combination you choose, the wear patterns can differ greatly, even with the same plain bearing.

Which shaft materials are better suited for your polymer bearings?

Hard Anodised Aluminium, AWM(P)

Precision (P) extruded hard anodised aluminium is perfect when trying to reduce weight and especially dissipate heat away from the bearing application. It is lightweight, has excellent wear resistance due to the hard-anodised surface, yet is durable and due to being corrosion- free, it is one of the most popular choices when looking for the best shaft/bearing combination. igus® offers hollow and solid shafts in certain diameters allowing further weight reduction if required.

CF53, SWM

CF53 is a cost-effective case-hardened ground steel shaft which is suitable for applications where high load capacity is required. It has a very low coefficient of friction against igus® polymer bearings, is tough and is available supported or partially supported.

316 Stainless Steel

The 316 stainless steel shaft has the highest corrosion resistance and yet is soft compared to X90, which means it is more forgiving when running against those more delicate specialist polymer materials. 316 is used in the highest FDA requirements and is the ‘go to’ material in the food sector. igus® also offer these as fully supported and partially supported.

X90 Stainless, EWM

This stainless-steel shaft has a high chemical and corrosion resistance, however, it is not as resistant as 316 stainless, and is for applications where strength is the main requirement. It is ideal with applications where demands are particularly high.

Conclusion

Depending on the application, the housing material and the bearing material will depend on the correct shaft material. Some shaft materials are significantly better counterparts for iglidur® polymer materials in regard to the wear rating, however, we have such a vast range of polymer materials and shaft materials that establishing the correct partnership is always possible.

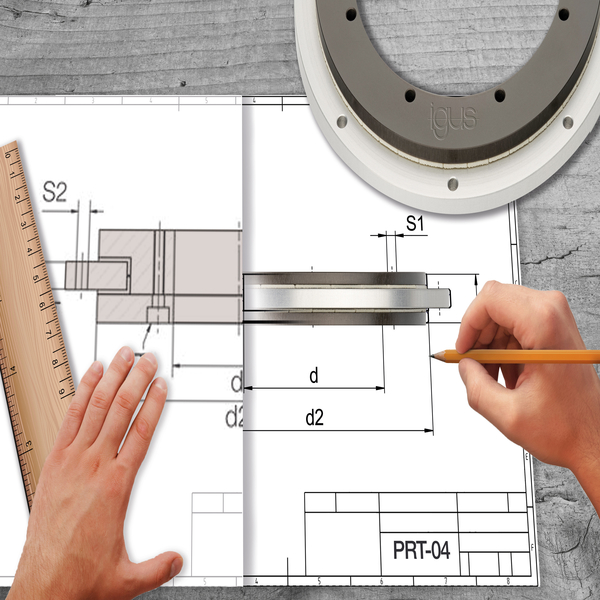

So, when considering your shaft and bearing combination, make sure you take all the elements into consideration. Not just the polymer materials for the bearing component but the matching shaft material. The igus® shaft configuration tool is great to be able to get quick prices. Get the most out of your bearings and if you need help making the right decision speak to us.