Travel safe products with igus® polymers

Do you know the importance behind vertical burn testing? If not, you really should!

Travel safe products are key in a society that prioritises protection and safety. Consciously and unconsciously, you, as a consumer or even simply as a human being, want peace of mind that whatever you are doing and whichever products you are utilising, the methods in which you use them are safe. At igus®, we are no different. We strive to create and manufacture products that are not only safe in the makeup of the product but also that we are creating materials and products that aid and maintain safety within their applications.

More and more, we are establishing that there is a need for specialised materials for specific industries and applications.

Never to shy away from a challenge, igus® is leading the way with testing and innovating new materials all the time to help support these functions. Recently we have seen an increase in the requirement for materials that comply with European fire protection standards – predominantly for the rail industry though we are seeing it more frequently in the aviation industry.

What this means in layman’s terms is that there is a necessity for certain products and materials to conform to a specific legal requirement. igus® can accommodate this with the introduction of iglidur® RW370. Let me explain how and why…

Background on the regulation EN45545:

The EN45545 safety standard requirement has become mandatory across Europe. This standard replaces the existing fire regulation BS 6853. The new regulations emphasise the tighter restrictions that are now required for materials and components used on railways. This includes: cables, seating, flooring, and even the physical shell of the train.

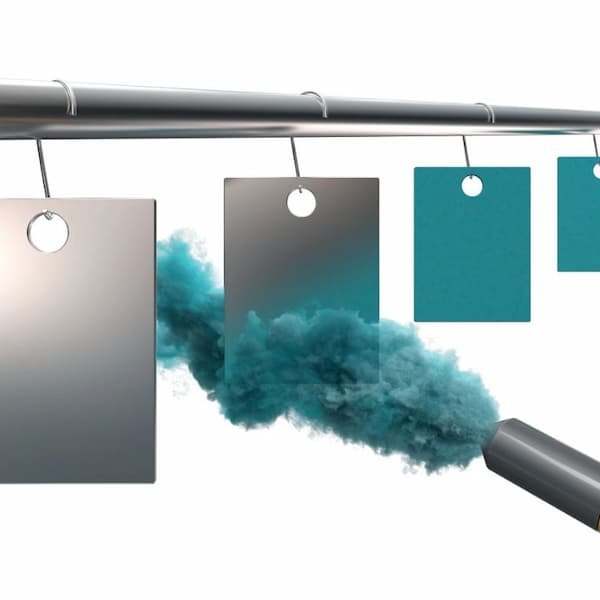

Definition of V-0 flammability:

V-1: burning stops within 30 seconds on a vertical item. As long as they are not inflamed, any part of the item that is still dripping is allowed. V-0: the same applies as the previous statement, however, the length of time allowed for the burning to stop is 10 seconds – so considerably shorter than the former.

How igus® can help with travel safe products?

When we think of fire we think of devastation, we think of how quickly the fire spreads and causes complete destruction. What’s more, we don’t necessarily associate fires and railways. However, if we were on a fast-moving train, the last thing we would want is a fire to occur on board. In such an event, we want to be safe in the knowledge that the fire will be contained, and the spread will be delayed enough to allow all passengers on board to alight safely.

The decisions and choices made by the engineers who design new trains, hugely impact on the safety of passengers and in this way, this regulation protects anyone that will travel on trains in the future.

We are not just involved in train travel safe products but you can find igus® parts in aircrafts, read more here

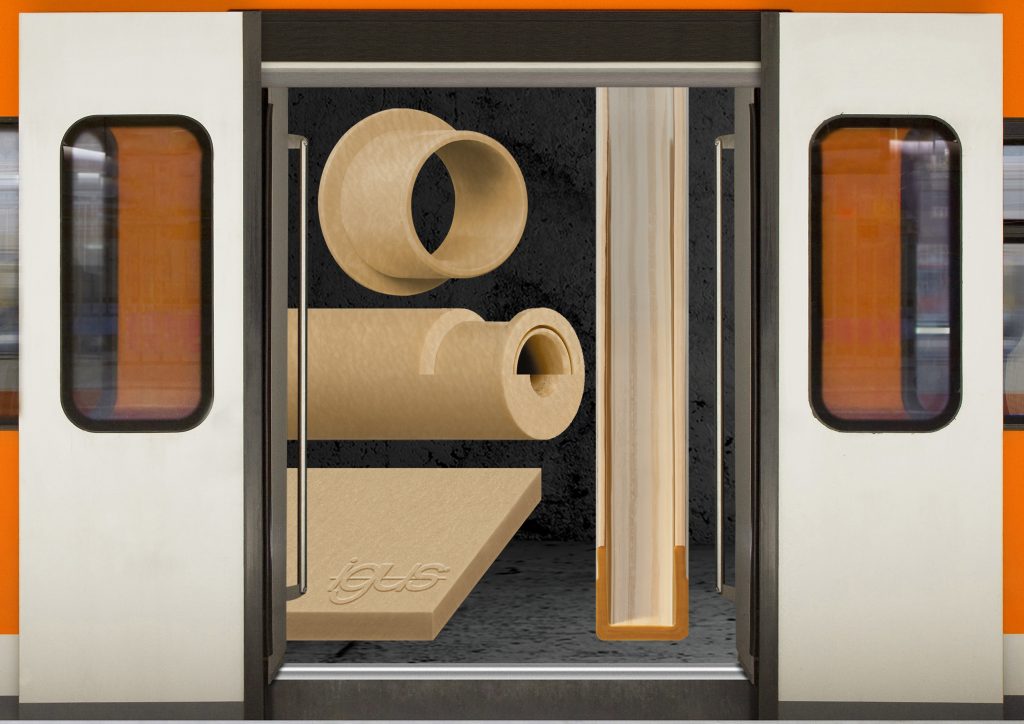

With the creation of the RW370, this has allowed igus® to support this safety feature. This material is not only flame retardant but still offers the typical igus® feature of high wear resistance without compromising on friction. Using polymers in place of metal counterparts offers a weight advantage and using lubrication-free igus® materials also helps with the low maintenance.

In true igus® style, we have created this material in stock bar, stock plate, our standard polymer bearings and also 3D filament. Having numerous travel safe product options allows for flexibility at the design stage.

Travel safe products remain paramount in all that we do so that if safety is a crucial aspect of your designs, igus® would be a key supplier to deliver this feature.