How do we test the articulated robot ?

The articulated robot robolink® undergoes most of its testing in the igus® headquarters in Cologne, Germany. The robolink® test lab is used for continuous testing and improvement of not only the individual gears and joints of the articulated robot but also of the assembled products. From this lab, we carry out 300 experiments per year across 5 different test rigs – giving a total of 49 test stations. In terms of usage, we have the test laboratory at 90% operation on a regular basis, keeping our customers happy and informed of any improvements or changes to the robolink®.

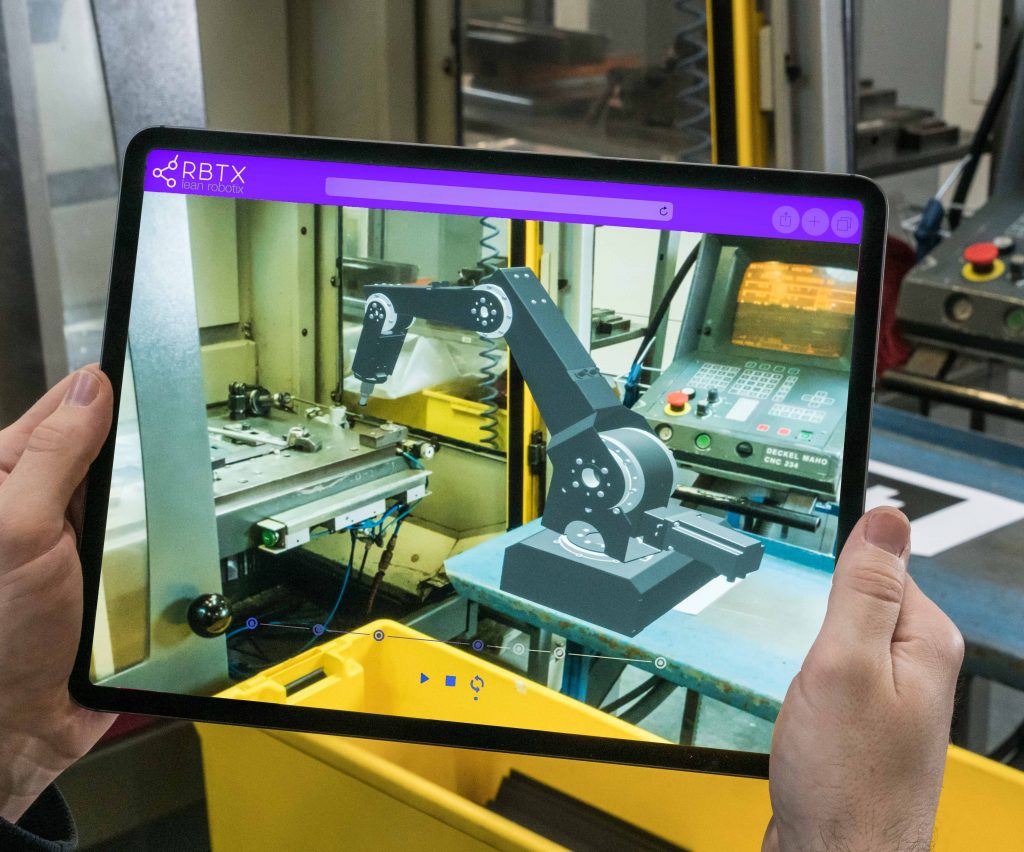

The main tests involve examinations of the following key features of igus® products: function, service life, strength, and failure scenarios. In most cases, a graph shows the predictions for each feature of the articulated robot. We find that graphs and images are easy to cast an eye over and a helpful indication of the suitability of our products for the task.

For function testing, igus® tests not only the hardware but also the functionality and repeatability of the software for this product. For example, while looking at the reach, bend radius’s and accuracy of the robolink® we will meet some areas of weakness and others of strength. We are able to identify key areas for enhancement, and areas to praise for their durability and flexibility. For service life testing, we investigate the effects of the changeability of working area, speed, and active endurance of the articulated robot. Following these tests, we are able to produce results in accordance with the long-life applications for which customers are able to use the robolink®.

In the realm of strength and failure scenario testing, igus® uses a variety of cast iron weights attached to the end joint of the robolink® as well as its individual component joints. With repetition, we are able to investigate the lasting strength, failure rates and aspects of the robot. In the endurance tests, we currently achieve more than 1 million at 5Nm and 12rpm. By reaching the limits of this robot and its components, we can ascertain and demonstrate the safety-rated limits of the articulated robot to ensure our customers meet their safety and functional requirements, as well as making the most of the investment they choose.

In addition to these, customers may request us to test specific applications in order to produce more accurate and bespoke results for their unique task. These tests are created and practised with a high level of precision so that our customers can rest assured that the robolink® will be the right solution for their automation issue.

For more blogs on robolink® articulate robot visit here.

Visit the website to find out more about the igus® articulated robot.

Alternatively, contact our Product Manager Adam Sanjurgo: asanjurgo@igus.co.uk for any robolink® enquiries.