Robot arms- How many does your robot need?

With the igus® robolink range, you have the flexibility to customise the robot of your dreams!

These modular robot arms allow the customer to create a unique system that automates manual steps quickly, improving productivity and efficiency. Automating production lines and processes is so important in production and we are seeing more and more people investing in robotics and robot arms.

With varying options in degrees of freedom, or DOF as we lovingly refer to it, you have a capability of creating your own individual solution for your application. Allowing independent coordinates to exist within a system, creates a unique structure to be able to specify the position of the complete system.

There are a multitude of industries that utilise robots, ranging from large car plants to small independent companies using them in pick and place applications. The large applications, such as being used on the car parts processing conveyor, requires a lot of freedom in the movement so having options is imperative. Robolink® allows the customer to have everything they need for cost-effective process automation from a single source: whole robot arms, individual components for individual solutions or to expand existing applications.

Low-cost robotics: what is Robolink?

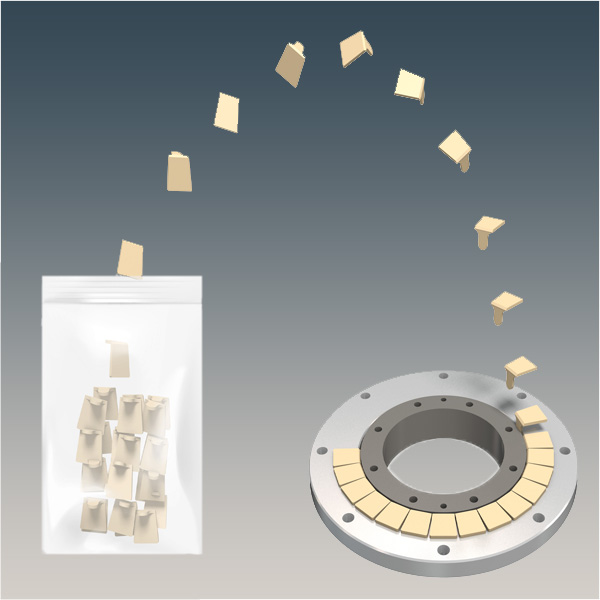

igus® introduced “low-cost robotics” to improve productivity with the help of simple and affordable automation. This comes in the form of robotics components which igus® named Robolink which is part of the low cost automation product group.

Depending on the scope and nature of the application, the customer can either automate the entire process or just part of it, whatever is required for the application.

Robolink® has gone through an evolutionary journey since igus® introduced it in 2009. It has been continually developed through the following decade, originating as an articulated arm with a rope drive to today’s optimised design; with more freedom of movement and a much larger load capacity. More recently igus® introduced a control system suited to robolink® with intuitive software.

So how do you know which Robolink will work for you?

The most cost-effective robot arms are the RL-DP with either 4 or 5 degrees of freedom, with a payload up to 3kg and a reach of 790mm for the 5 DOF version. This design has been made more rigid in comparison to the previous models and now comes with robot control with a very simple interface to control your robot.

The nature of the application will depend on the robot. igus® have designed the range to have optimised flexibility so you can either:

- pick a standard complete robolink® robot, consisting of the robot’s arms, perfectly matched control system and software.

- Build your desired robot arm and combine it with a different software programme.

- Build a customised solution. This option allows you to configure your desired robot with the robolink® designer.

The beauty of Robolink® is the flexibility. igus® has not only created robolink® with options for the customer, but the applications these little robots can be used in is endless.

A recent example of a robolink® robot being used, was on the Gadget Show, Channel 5 for a feature celebrating its 400th episode. The robot was programmed perfectly and the precise, yet gentle movements showcased the robot’s abilities to light the celebratory candle.

In case you missed it….

If you need help deciding how many arms your robot needs, igus® can help you with configuring it and offer support from the initial enquiry until completion.

Automation is the future, to work alongside humans in processes to ensure productivity is as high as possible.

For blogs relating to low cost automation, click here.

Please visit the igus® website for more information. Alternatively, please contact the Low Cost Automation Product Manager Adam Sanjurgo:asanjurgo@igus.co.uk.