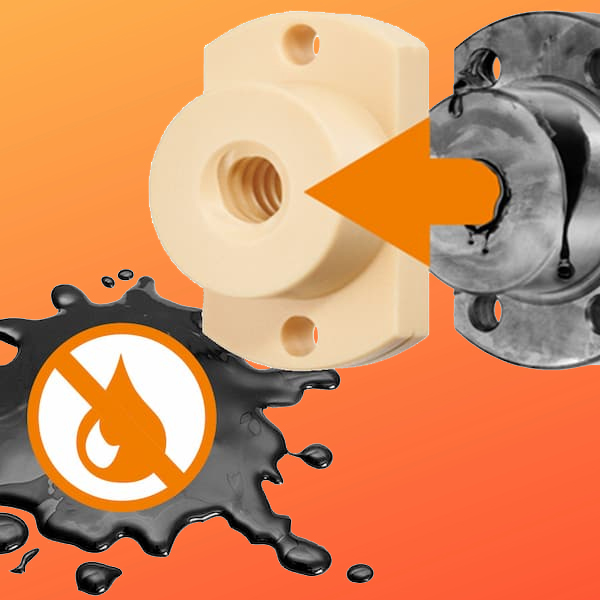

Bearing lubrication; 3 important reasons why you shouldn’t lubricate bearings

It is important to know the facts. Once you have the facts you can make an informed decision. Lubricating bearings is not necessary in some circumstances and it can in fact be detrimental to some products if you do. This blog identifies the top 3 reasons why you shouldn’t lubricate bearings.