Top 5 iglidur® polymer bearing materials

“Show me the plastic part that gives you a problem. I’ll provide you with a solution!”

That sentiment is so prominent in the igus® world, we strive to be able to help solve every problem thrown our way! With over 50 different polymer bearing materials a solution is always plausible, but what I realised was, probably 90% of the problems we are given by customers, we can usually solve with one of the 5 most popular materials.

Let me introduce the 5 big hitters:

iglidur® G, the classic all-rounder

iglidur® G is the original. This was the first igus® polymer bearing materials released. This economical all-round performance bearing does exactly what it says on the box. It is perfect for medium surface speeds, for oscillating and rotational movements and has a high wear resistance. It is also the most cost-effective bearing, offering low cost combined with good mechanical, thermal and tribological properties. With over 650 sizes available from stock, this has the largest range of standard catalogue parts. It is easy to see why this is called the “all-rounder.”

iglidur® M250, the robust all-rounder

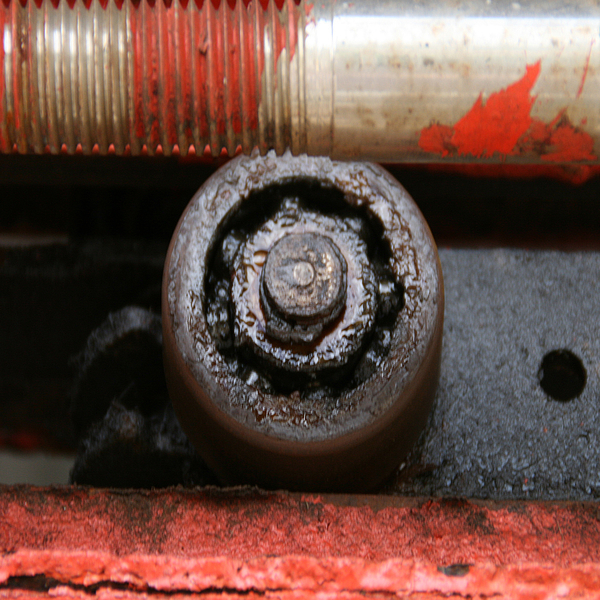

M250 suits robust applications and is defined by its impact strength and proven by its ability to absorb shock loads. M250 has excellent wear-resistant properties, so it is no surprise that this material excels in applications in which resilience is necessary. These thick-walled bearings are designed for high impact and resistant to edge loads, so they are ideally suited for agricultural machines and garden appliances, they are also often used to replace steel or bronze counterparts.

iglidur® J, the versatile endurance runner

iglidur® J is known for its endurance and works at its pinnacle when running at low and high speeds with medium loads. This doesn’t mean it is restrictive however, it can keep up with the best of other igus® polymer bearing materials. One of the main advantages of iglidur® J is the combination of a low coefficient of friction and low wear on most shaft materials. This is where its nickname originates from. With low friction, especially when running on hard anodised shafts, iglidur®J eliminates the problems created by stick-slip, which means it has the same breakaway friction as running friction.

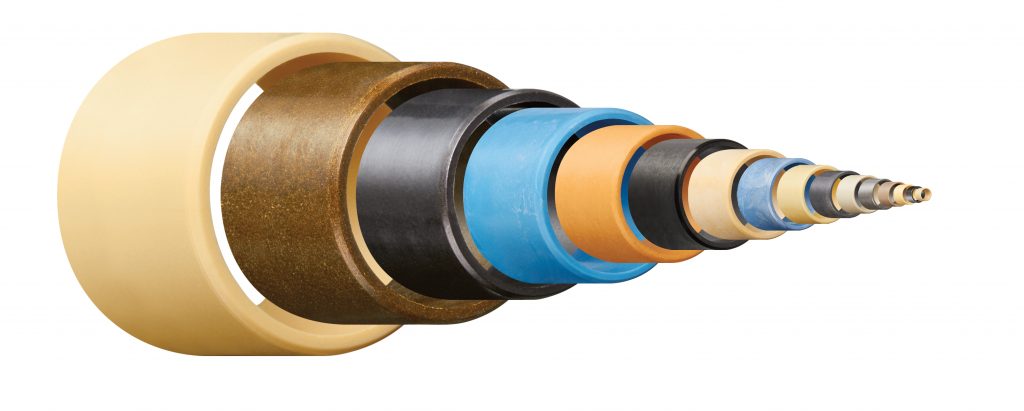

iglidur®A350, the endurance runner at high temperatures in the food sector

This is everything you need in a food-grade bearing. A350 conforms to the typical identifiable blue colour and is FDA and EU regulation N⁰-10/2011 approved. It can be used in applications where temperatures reach over 180°C. This material is well suited to both low and medium speeds in oscillating and rotary applications. The adaptability of this material is highlighted in some of the other properties. Not only is it high chemically resistant, but it is also resistant to numerous other media and hostile environments. It is resistant to radiation, as well as resistant against UV and is also electrically insulating. This accentuates the versatility of this material and illustrates why it is one of the top favourites.

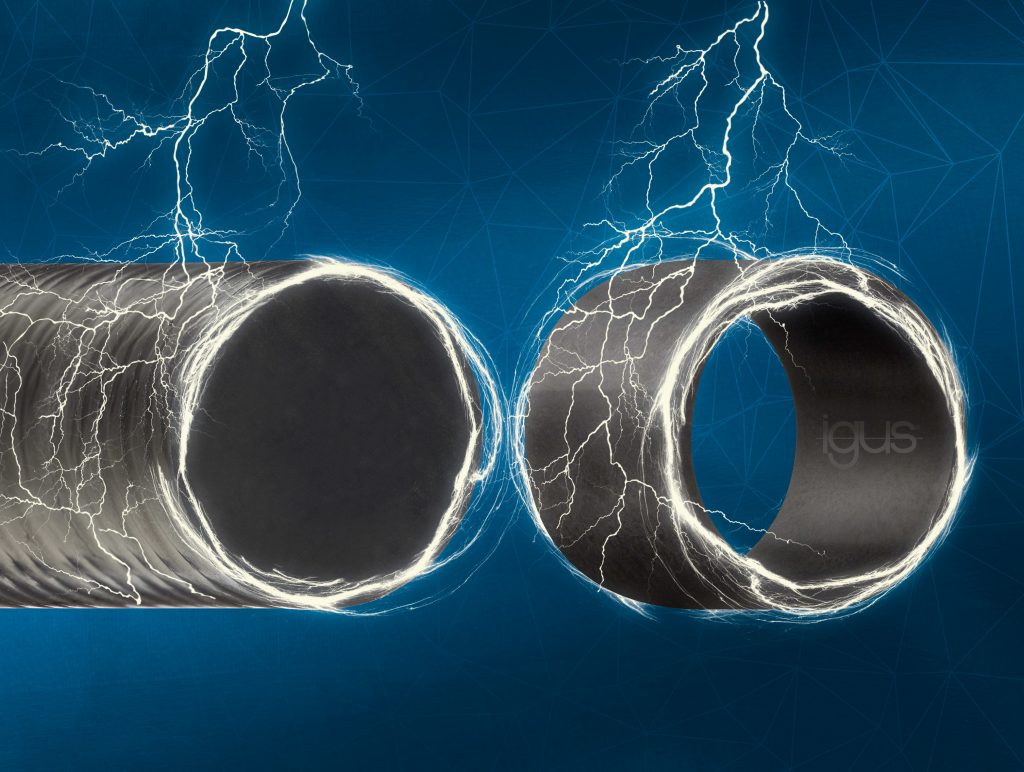

iglidur® X, the high-tech problem solver

iglidur® X is the boss of the 5 polymer bearing materials. It is defined by its combination of high-temperature resistance with compressive strength, along with high resistance to chemicals. It has been designed for higher speeds than other iglidur® polymer bearing materials, especially at high temperatures.

It has the lowest moisture absorption out of the top 5, withstands the highest temperatures and has the best chemical resistance.

It is chosen for use in aircraft interiors as it conforms to the fire prevention requirements of the Federal Aviation Administration of the USA (FAA). It is also one of the only igus® polymer bearing materials that can be used in a vacuum. You can see why this is the boss!

So, as Günter Blasé said in 1964; “Show me the plastic part that gives you a problem. I’ll provide you with a solution!” If one of the favourites can’t produce the result you need, we have another 45 materials that will definitely suit.

Find more iglidur® related blogs here.