What does your crane application need; a busbar or energy chain?

Busbar or energy chain? The performance and reliability of a crane is directly dependent on how power reaches the system and these systems are huge and expensive so ensuring you chose the correct system could save you thousands of pounds. There are various power supply options available and each option has certain parameters and requirements to be considered. This can mean that selecting the best type of system to implement can be complicated but as it is essential, it is crucial that all advantages and disadvantages of the systems are considered.

Here we look at 2 possible options; Busbar and energy chains.

Busbar or energy chain

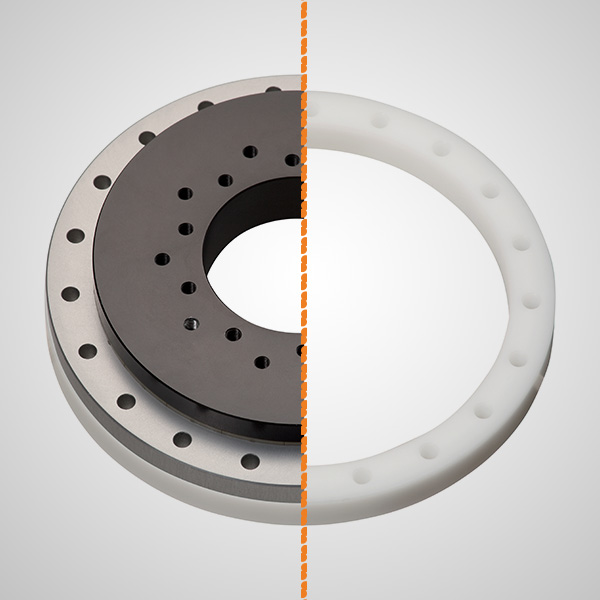

Busbar

Busbars or energy chains? Busbars have historically been popular power supplies for cranes. However, busbar systems do have some shortcomings. One of the main problems is that busbars requires downtime for maintenance as they require frequent inspections. This is not only inconvenient but expensive!

Busbars are also limited in the type of energy they can supply. On a busbar system, each conductor requires its own conductor bar and collector. To add additional conductors should they be required, extra conductor bars must be installed on the hanger brackets. There is usually issues with space restrictions, so this is sometimes not a feasible option. This limits busbars usability. Another potential set back for the busbar system is should there be a requirement for additional hoses or other cable types. These have to have a separate system. This is important to consider when looking at intelligent plastics; Industry 4.0 and again whether the logistics of additional external cables are feasible.

Further difficulties with busbars continue with the exposure of bare loaded conductors to the surrounding environment. This then becomes a health and safety concern, Something many companies simply cannot have, especially when dealing in hazardous or explosive environments. Busbars are not suited to these environments and can become a costly choice if dust or debris are in the air. Problems such as corrosion, which is likely in applications installed near seawater occurs causing devastation for the system.

energy chains

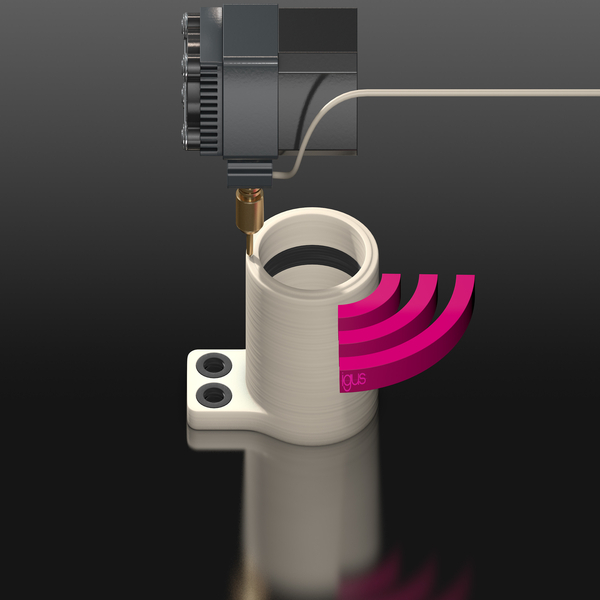

igus® e-chains® are uncomplicated. They are constructed of parallel side links that connect with crossbars along the top and bottom of the chain. As a plastics specialist, we have specific designs and materials available which suit various types of motion and environmental applications. Unlike steel systems, plastic energy chains are designed to resist abrasion and corrosion.

The igus® e-chains® are lighter than steel and are 100% maintenance-free. Our e-chains® can carry all types of cables and hoses in a single system,. These include power, data, fibre optic, media and hydraulics. Our chainflex® cables are designed with jacketed multi-conductor cables for continuous flexing applications. We are so confident in our products that we offer 4 year guarantees on our e-chains® and cables.

With the e-chains® systems, it Is also easy to change the cables if required. These are secured to the chain with strain relief clamps, which are installed at each end. If the cables need to either be replaced or upgraded, the existing cable can be released from the ends and used to pull in a new cable.

The tribologically optimised polymers that the e-chains® are manufactured in, allow them to remain stable, even when subjected to high loads, high temperatures and adverse weather, showcasing the primary reason the energy chain is more suited to crane applications than the busbar.

So which is best? Busbar or energy chain?

Want to find out more about cranes? Visit our frequently asked questions section here: https://blog.igus.co.uk/faq/faq-industry/ports-cranes/

Industries that e-chains® are commonly used in are other than the crane industry are agricultural, automotive, material handling, packaging and Robotics.