Do I need to lubricate bearings if they are plastic?

Do you need to lubricate bearings? Not with igus® products! It is no secret that igus® is an advocate for not lubricating bearings. However, this doesn’t stop the reoccurring question from customers, “can I use WD-40 to lubricate my bearing?” Many people think that because for some products it is essential to add grease and lubricate bearings to ensure that they don’t seize and they continue a smooth-running motion, it is not a requirement for ALL products.

It is a misconception that we are trying to tackle daily, a misconception which, if was changed, as customers you would not only save money but also help eliminate unnecessary lubricants being released into the environment. This is crucial to help protect the world.

This blog is to reemphasise you don’t need to lubricate bearings if they are igus® polymer bearings. It is also to explain why you CAN use WD-40 but why you don’t NEED to. Obviously, there are other forms and brands of lubrication but this is a universally renowned one that is regularly mentioned so I will use this as my example.

Let’s look at what WD-40 is.

When you dive a bit deeper into the makeup of WD-40 it could be seen as not the best product potentially to use if your aim is to keep a bearing lubricated and not impact on the friction. This is due to the fact that WD-40 is referred to as a “penetrating oil”.

What this means is that it can seep into cavities and mixes with dirt and dust particles, bringing them to the surface of the bearing. This lubrication is also not feasible as a long-term option due to the runny consistency of it, it isn’t long lasting as a lubricant and dries out very quickly.

Does using WD-40 effect the performance of igus® bearings?

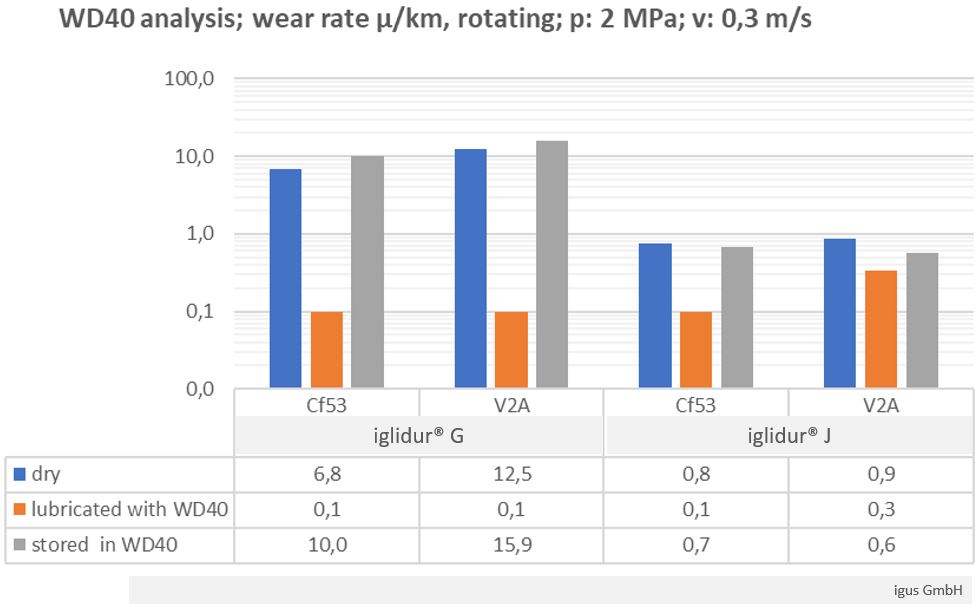

To obtain answers to questions like this it is essential that we run tests in the laboratory. So, that’s what we do. We have chemical tables to show the effects of WD-40 against the iglidur® materials. These tests show the mechanical strength as well as other properties and abilities. All of these can be found here (will link)

Controversially though, the results indicate that the iglidur® materials are in fact resistant so surely it can’t be detrimental if customers lubricate their bearings with WD-40? At this point we have to look at resistance and wear effect as two separate issues. Yes, the materials are resistant to such oil lubricants, however this doesn’t mean that they don’t affect the bearing. Further, different tests show that the bearings react differently over certain periods of time.

So, why don’t I need to lubricate bearings with igus?

Although initially the lubricated bearing performed the best, this was a short-term result and required a fair amount of WD40 to get those results, far more than people normally would consider using.

After 4 days of continuous rotation in the test laboratory, both the dry running bearing without lubrication and the lubricated bearing showed similar amounts of wear. This allows us to conclude that in theory there really is no reason to lubricate igus® bearings with any lubrication, including WD40, which as previously mentioned is not designed for long-term use and once dry can leave small residue particles on the bearing, potentially leading to increased wear and noise. If you lubricate bearings, consider igus® bearings for long lasting lubrication-free motion plastics.

If you would like to read more about lubricating bearings and why it is not necessary with igus® products then click here https://blog.igus.co.uk/bearing-lubrication-why-you-shouldnt-lubricate/

Find out more frequently asked questions about igus bearings here