ATEX standard: How can dust cause an explosion?

Have you ever heard of ATEX standard? Once you have an understanding of this vitally important feature, it is difficult to ignore.

It really shouldn’t be ignored!

This standard is all about safety and ensuring that products are suitable for their surroundings. If this isn’t considered, the consequences can be catastrophic

What is ATEX standard and why is important?

ATEX is a European standard for explosion protection & avoidance. The acronym ATEX derives from the French abbreviation “ATmosphères EXplosibles” and is covered by European Directive 2014/34/EC. It is also the standard to which igus® ESD materials must be compliant.

How does this directive coincide with igus® products?

As far as igus® is concerned, when meeting with a customer, this makes ATEX “THE” environmental question when considering the parameters for products in such environments, especially if there is going to be a lot of static discharge. It is amazing where this occurs and how severe it can be if the static discharge is not grounded.

There are two explosive environments covered by ATEX standard and these are ignition sources in the form of Gas and Dust. igus® products are renowned for working perfectly in dusty environments due to their lubrication-free properties, so having a range that is covered under the ATEX directive was essential.

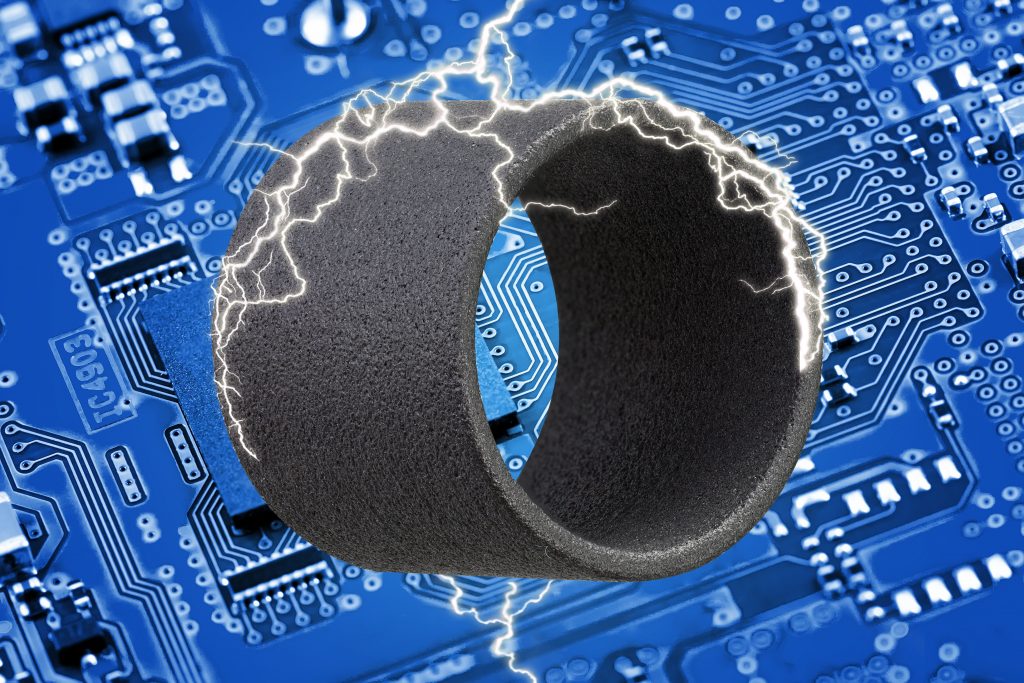

Thankfully igus® have a range of products that are conductive despite being plastic. Conductive iglidur® materials are recommended to avoid electrostatic discharges and the iglidur® materials with highest conductivity-/lowest volume resistivity on the bearing side are:

- < 10³ Ωcm: iglidur® F

- < 105 Ωcm: iglidur® H, iglidur® H370, iglidur® X, iglidur® X6,

- < 109 Ωcm: iglidur® F2, iglidur® UW500

When used in ATEX environments, iglidur® bearings need to be tested together with their shaft counterparts and the system surrounding them, to ensure the combination of all elements are suitable.

One of the new igus® products released this year was the I8-ESD SLS 3d printing material. Offering a 3d printed material with excellent service life, hard wearing and that is electrostatic dissipative means igus® can provide moving parts quickly and cost-effectively.

Similarly, for igus® energy chains, the material igumid® ESD is used. This conductive material is essential in some environments due to the potential static build-up within the rotating parts of the e-chain®. Using this conductive material allows the static to be dissipated and in order to ensure that this is correctly grounded, metal or ESD certified mounting brackets are used.

Once fitted, the whole system must be tested and certified by the customer to ensure its suitability for the respective environment, as it is just one part of an often-complex system.

Dust: how and why does it explode?

How dust can react in certain situations is underestimated. It can cause massive explosions when fine particles rub together suspended in the air in an enclosed location. The dust explosion occurs where dispersed powdered combustible material form a network of dust particles. They are so intricately intertwined that as soon as one ignites; the rest rapidly follow, and a dust explosion occurs.

High-risk environments are:

- Biomass power stations

- Paint spraying robots in car plants

- Flour mills

- Oil refineries

How can igus® products help?

There are many features of igus® products that could help in such environments, in addition to offering options in conductive materials. The products are also lubrication-free which means no additional accelerants in the form of oil or grease. igus® offer a range of both polymer bearings and energy chains that are conductive and can help with the technical side to any applications. Just give us a call.

For more blogs relating to our ESD products click here.