xiros® rollers for labelling technology; guiding products quietly and effortlessly

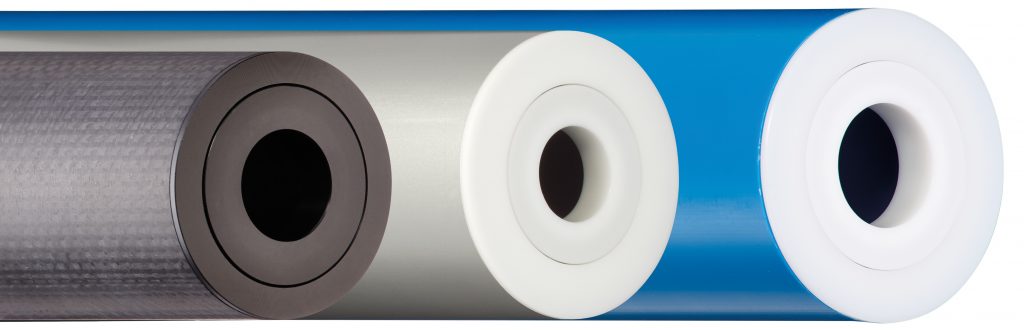

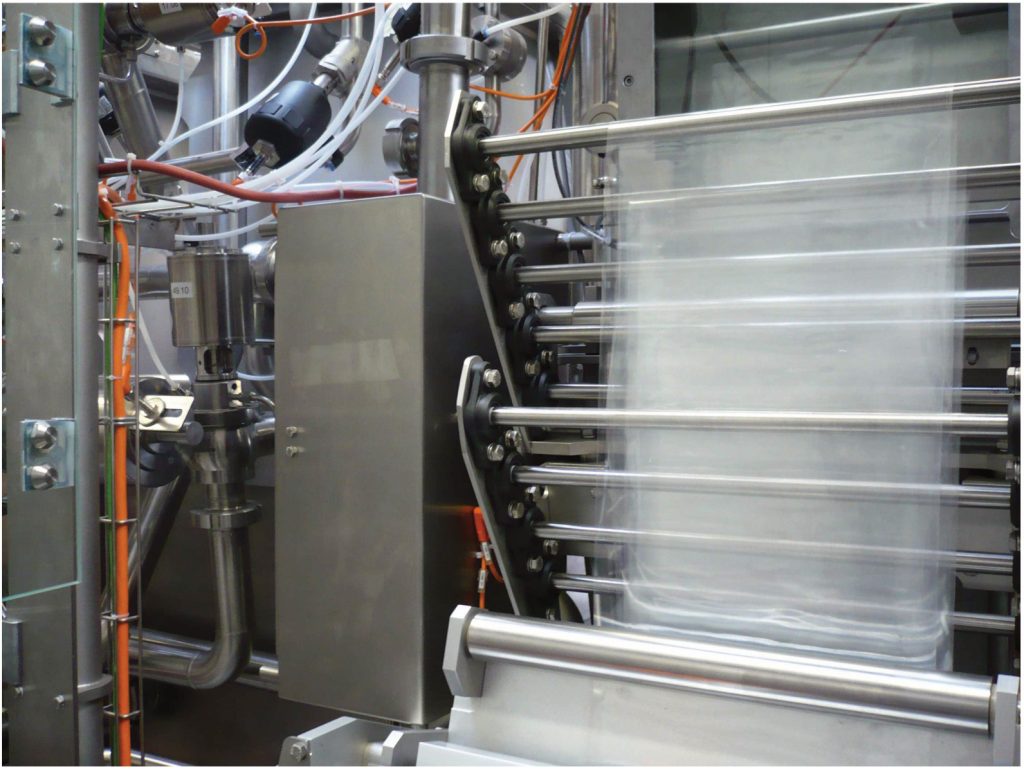

The xiros® roller has been around for a while, understated, discrete and quietly improving applications in the background. These rollers are continuously being developed and enhanced to ensure their flexibility is suited to multiple applications and industries. The newest design is the black guide rollers, which are produced in black anodised aluminium and fitted with maintenance-free, smooth-running xiros® polymer ball bearings. Historically the rollers were produced in clear anodised aluminium, so the introduction of the new black guide roller provides a real twist to products available in packaging and labelling technology as well as the printing industry, to help reduce light reflection. The ready-to-install system is not only visually appealing aesthetically in black but also technically competent. These rollers are ideal for diverting films or in labelling applications and offer significant advantages over steel rollers.

Here are some of the advantages of xiros® rollers over alternatives:

- Maintenance-free

- Low friction/inertia

- Low noise

- Iglidur® F180 material is electrically conductive and this material can reduce static build up

- No lubrication

- Lightweight

xiros® polymer ball bearings are renowned for being lubrication-free, maintenance-free and hygienic and they have a very low breakaway torque. It is thanks to those certain specifications that, as mentioned previously, they are highly sought after and used in the field of packaging and food technology. Although other industries are using these rollers, such as airport handling equipment industries, the bulk of our sales are for rollers designed into industries such as labelling machines and the paper industry. igus® supplies these rollers as fully assembled systems with a tube made from either aluminium, carbon or PVC, plus the two bearings installed. We can also deliver with shafts fitted to suit your requirements which can be made from various materials to your drawing specification. Offering them as a complete solution saves the customer time and effort at the assembly stage and they can be easily designed in at the initial stages of application design.

The introduction to the black aluminium roller came from a customer enquiry. The technical specifications of our classic aluminium rollers were already very appealing, but due to the aesthetics the customer required black.

There are a variety of ball bearing combinations to be used within the roller; the race, balls and cage materials can all be altered to suit the application. By using wear-resistant high-performance polymers and thin-walled tubes, the rollers provide a weight saving of up to 48 per cent compared to metallic solutions. Their mass inertia is 42 per cent lower, therefore, the energy required for acceleration is considerably lower without compromising the rollers conveying speed.

As with any of the igus® products, the idea was put forward, prototypes were designed and created, and tests were started. After extensive testing, the results were positive and showed nothing detrimental in comparison to the original clear anodised aluminium roller. A new product was born.

With flexibility in ID, OD and roller length, it is beneficial to take some time to look at the configurator page or speak to one of the igus® specialists. They can offer virtual or physical assistance with a cost down, life up ball bearing solution.