Bearing lubrication; 3 important reasons why you shouldn’t lubricate bearings

Bearing lubrication, a topic we wrote about last year, which you can read here: https://blog.igus.co.uk/do-i-need-to-lubricate-bearings/ but this new blog is more lead screw specific.

A misconception when it comes to lead screws is the insistence in greasing them! Granted, some products require lubrication to ensure that they do not seize up, however, it is easy to forget that lubrication is not a prerequisite for all products. And with any igus® products it is simply not needed, so please save yourself time and money and don’t bother!

3 reasons why bearing lubrication isn’t needed with igus®

Reason 1 – Waste of money

Our lead screw systems are developed for maintenance-free and completely dry operation, meaning no bearing lubrication is required. With this in mind, you cannot really compare a lubricated lead screw system with a dry-operating system. They operate differently because of the external lubrication used. Lubricants can cause a high maintenance effort and additional costs that are often not accounted for.

With igus® dryspin® products, the lack of lubrication required is down to the homogeneous structure of the lead screw nut material. This ensures that any wear is mostly linear, wear can be calculated given application specifics and therefore maintenance intervals can be scheduled in.

Our materials are characterised by their special specifications: their unique composition makes them extremely wear-resistant and resilient to almost any environment. Due to the self-lubricating effect, the lead screw nuts are 100% dry-running and maintenance-free. Their special composition makes them extremely wear-resistant, robust and self-lubricating. Therefore, using igus® products means no grease, saving you money.

Reason 2 – Contamination

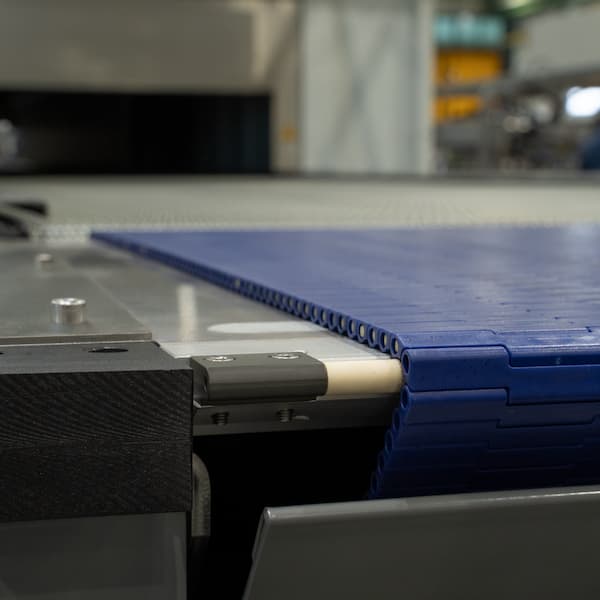

Bearing lubrication can penetrate cavities, mix with dirt and dust particles, and bring them to the surface. Particles such as dust and fibres can adhere to conventional lead screw drives due to the grease or lubrication used. In dirty environments, this greatly decreases service life. In comparison, when using igus® products you will increase the service life. No dust particles are able to grip to the lead screw, therefore they are ideal for both dirty and clean environments.

Cleanroom applications demand products where contamination is not acceptable, and dryspin® products are ideal for this. The above-mentioned advantages make it possible for dryspin® lead screw drives to be used in special industries, such as food and packaging, medicine or pharmaceutical technology to name just a few. These industries make it mandatory that the installed products are absolutely clean, hygienic and very easy to maintain.

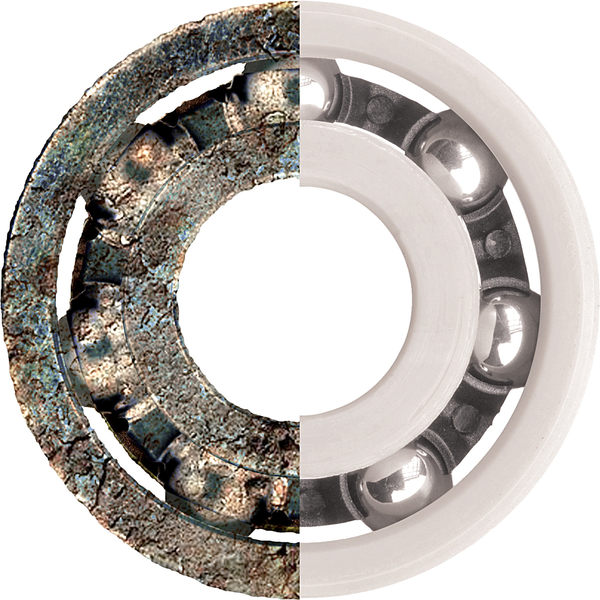

Reason 3 – Bearing lubrication can decrease the life of the bearing

As a rule, our materials are resistant to certain oil-based lubricants, but the use of these lubricants could possibly affect the lead screw nut in a negative way. People will always insist on bearing lubrication as a solution and if this lubrication is not done consistently, issues arise with wear and seizing. Having the lubrication internally within the iglidur® material allows smooth running without having to grease. This is the key to a long service life.

Ultimately, that is what you want, a long service life for your bearing, without contamination and saving money.

Need I say more…..