Is electrostatic discharge important in moving parts?

Friction caused within machines is inevitable. But what is important is how you dissipate the static discharge. It can cause permanent damage to the product or machine if it is not removed. Components made of wear-resistant iglidur® polymers do not require additional lubrication. However, unlike their metallic counterparts, these polymers cannot dissipate the electrostatic discharge. How do we counteract and protect these components from irreversible damage? We need a controlled discharge. So, what is ESD and how do igus® products do this?

What distinguishes an electrostatic discharge material against standard materials?

Electrical discharge can be referred to as ESD (electrostatic discharge). The cause of an electrostatic discharge is the friction of two insulating materials against each other. In everyday life we encounter this physical act of getting static shocks when we walk over carpets with plastic shoes.

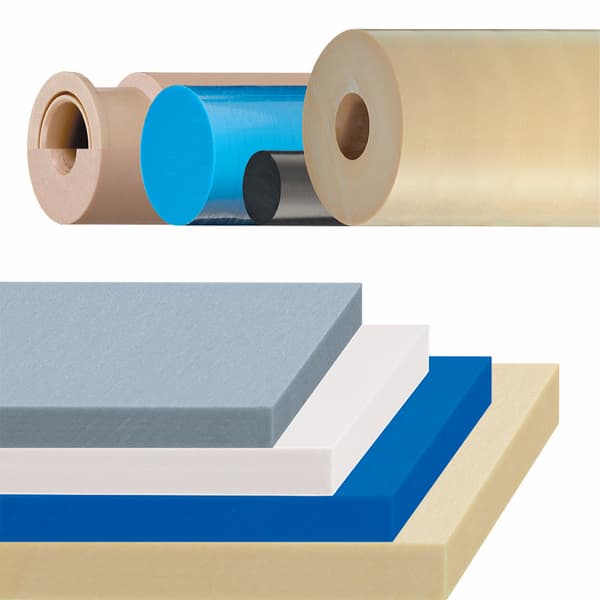

Within the igus® range, there are multiple products available in an ESD material. This ranges from energy chains, bearings and bar stock. All of these have antistatic specifications. But for this blog I am going to focus on the new 3D printing material.

For further information about the dangers that can be caused by antistatic polymers, you can read my blog: https://blog.igus.co.uk/atex-how-can-dust-cause-an-explosion/

iglidur® I8-ESD and its material properties

igus® has recently launched an ESD laser sintering material onto the market. The iglidur® I8-ESD material has been developed for specific applications. Applications where dissipative electrical material properties need to protect sensitive electronic components. This material and manufacturing method enables the additive production of prototypes, production parts and spare parts, All of which confirm to ESD specifications.

In addition to the static conductivity, iglidur® I8-ESD has a high abrasion resistance compared to a standard PA12 laser sintering material. This makes it stand out from the crowd and is ideal for all applications where electrostatic charges must be avoided.

The specifications:

- Lubrication-free and maintenance-free

- Abrasion resistance

- Electrostatically dissipative (ESD)

- Colour: black (solid)

- Increased rigidity

- Available as laser sintering powder or from the 3D printing service in 1-3 days

iglidur® I8-ESD as powder or print components

iglidur® I8-ESD is suitable for use within regular laser sintering machines. The material can be purchased as laser sintering powder and processed on standard equipment. For those customers who do not have their own laser sintering machine or only need a few parts from it, can order the components from the igus® 3D printing service – delivery takes 1-3 business days.

Electrostatic discharge must be dissipated correctly otherwise it can be extremely dangerous. It is important to keep safe and ensure the right materials are chosen for your application.