Find out why 3D printed gears are the future!

When you think of gears, what is your first thought? I am confident that the first thought is not 3D printing them! So, this blog is to challenge your thoughts and the misconceptions surrounding 3D printed gears and to give you an insight into why more and more people are either 3D printing their own gears or getting us to do it for them…

Back to basics

Let’s start with some basics, what are the types of gears that igus® frequently 3D print?

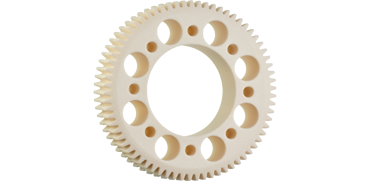

Spur Gears

These gears are commonly known as gear wheels or straight-cut gears. They are the simplest of the gear family and consist of a cylindrical bore through the middle with teeth projecting parallel to the wheel axis. The main 3D printed material that igus® uses to produce these is iglidur® I3. The I3 material is a high wear-resistant material with excellent stability and mechanical properties. The material has an abrasion resistance up to 30 times higher than conventional 3D printing materials. This makes it the perfect material for gears.

Worm Gears

Worm gears are more of an assembly arrangement consisting of a worm screw and a worm wheel. Using an assembly allows the rotational speed to be determined by the user. Because of this allows for a higher torque. With this type of gear, igus® recommends iglidur® I6. This white material is extremely tough and abrasion resistant. It is also FDA compliant so can be used in food applications! This material was designed to be used for the gear industry. With the 3D printing method rather than traditional milling, the design flexibility has fewer limitations.

Bevel gear

The bevel gears again have a partnership, with another bevel gear! These conically shaped gears work in harmony with each other. They mesh the gears together like a jigsaw. Usually these gears are mounted on shafts, which are 90 degrees apart. The material recommended for these gears would again be the iglidur® I3 for the same technical aspects required for the spur gears.

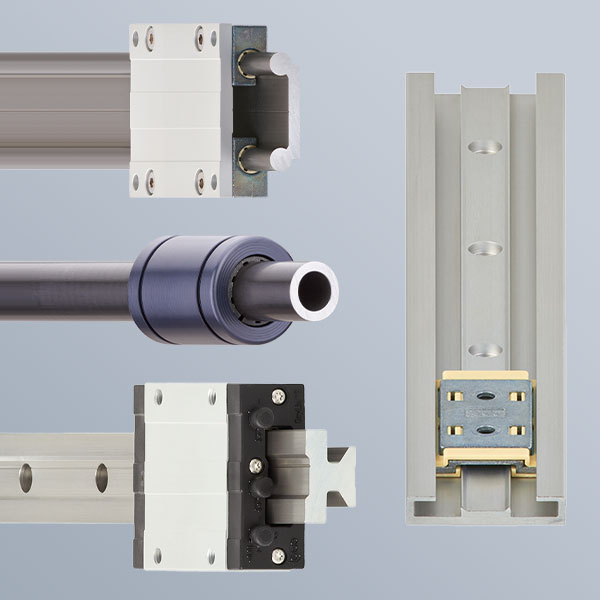

Rack and gear

Technically not a gear but something that we do get asked for is rack which goes hand in hand with traditional gears. This can be an alternative to belt drive, turning rotary motion into linear motion.

To make life even easier for the customer, there is not only a gear service life calculator but also a 3D printed gears CAD configurator, all completely free!

This allows customers to configure their gear, get an idea of the service life and order them quickly and efficiently with no tooling, no set up costs, no long lead times and best of all, no minimum order quantity. So, ask yourself, what is preventing you from trying the igus® 3D printed gears…??

For more blogs relating to 3D printed gears as well as other components, visit here.