How does an electric motor work?

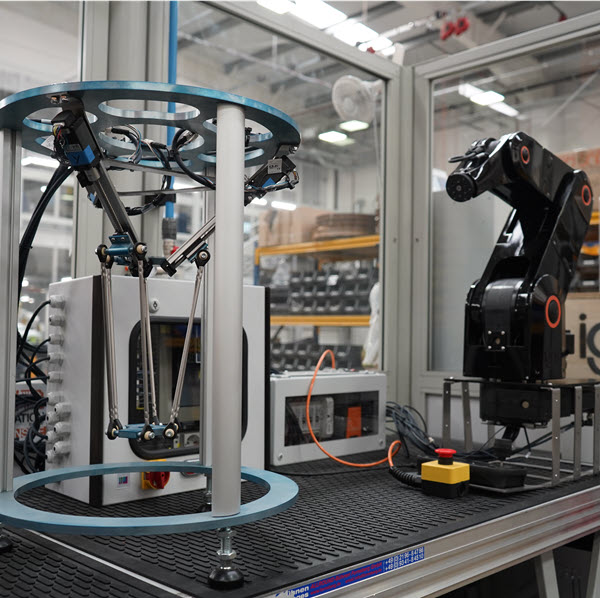

Electric motors are devices that convert electrical energy into mechanical energy to be used in various applications from simple household appliances like washing machines to industrial machinery such as conveyor belts and power drills.

Electric motors are an essential part of factory automation. Learn more about improving your processes with automation here.

So how do electric motors work?

In short, electric motors work with magnets, electromagnets, and electricity to generate movement. Motors can run off a direct or alternating current and are often referred to as DC or AC motors as a result. In this resource we will go through both and look at the range of motors igus® can offer.

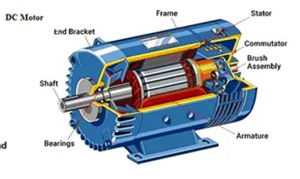

DC Electric Motors

DC motors include two key components: a stator and an armature.

The stator is the stationary part of a motor that provides a magnetic field which allows the armature to rotate. A simple DC motor uses a stationary set of magnets in the stator and a coil wire running through it to generate an electromagnetic field. This magnetic field is then concentrated by wrapping insulated wire around the core of the motor.

When the coils are powered, a rotating magnetic field is created, causing the shaft to rotate.

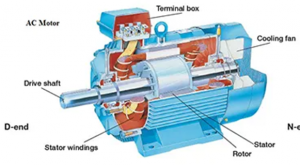

AC Electric Motors

Unlike direct current, an alternating current is when the electric current periodically inverts direction. AC motors rely on a device known as an alternator to produce this alternating charge which in turn generates its electromagnetic field.

If the AC motor is correctly designed, it will be a power source for a whole host of applications that’s flexible, efficient and functions with little noise

Diagrams sourced from Kinmore.com

igus® Electric Motors

If you want to automate an application, there are plenty of ways to do so. igus® have a huge range of electric motors available with different properties designed to cater to your application. DC motors are used in lead screw drives, toothed belts and rack and pinion drives and so entire handling systems can be configured in combination with linear axes. If you know exactly what you’re looking for, you can order instantly online at www.igus.co.uk or request support from our team here.

Types of igus® Electric Motors

At igus®, although we don’t provide AC motors, we do provide motor control systems which works together with a switchboard (or multiple) that controls the movements and powers the motor. If you need convincing of the benefits these systems have, we can offer free sample programs with each system so you can try the programming software for yourself!

Find more information on this here

Powering your system

The drylin® power supplies for automation are suitable for all dryve motor controls. They supply output currents in order to be able to operate the entire igus® motor series. The 24V output voltage is typically used to supply stepper and DC-motors, whereas EC/BLDC motors have a 48V output voltage.