igus® E4.350 energy chain vs steel drag chain

When designing an energy chain into an application within the oil and gas industry, there are various parameters which need to be considered. It is also important to understand why certain chains get specified at the design stage over others. So, why would an igus® energy chain be more suitable than a steel drag chain in this industry?

Traditionally, the oil and gas industry has favoured stainless steel drag chains. This is due to a number of factors, including the historic preference of steel chains from when the early oil platforms were built. Many retrofits have been carried out, with a like-for-like replacement, making steel drag chains the norm offshore. People are creatures of habit and don’t like change, so it is imperative that they see the benefit of change and understand the advantages of replacing steel chains with igus® energy chains.

Here are a few benefits of why an igus® E4.350 e-chain® might be better suited over a traditional steel drag chain:

- With igus® e-chains® not only is there is an obvious cost saving from a purchasing point of view, but customers also save money by increasing the lifetime and reliability of the energy chain. The E4.350 energy chain reduces downtime by eliminating the need for any maintenance due to its moving parts being produced using self-lubricating polymers.

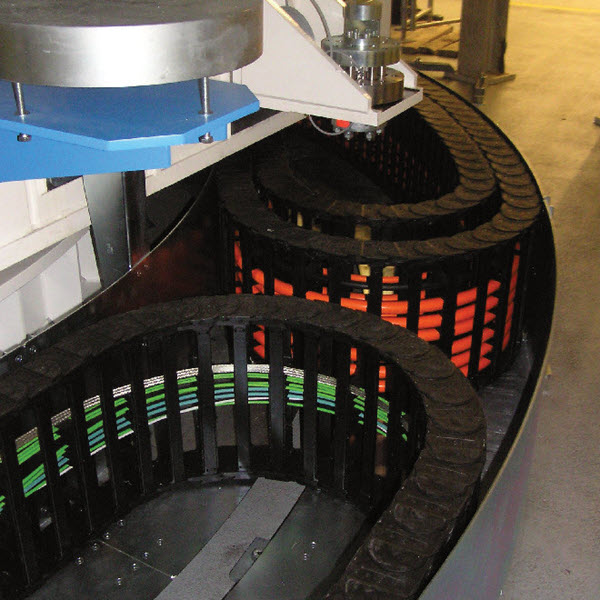

- At times there appears to be a common misconception in the industry, that larger energy chains must be made from steel. The introduction of the E4.350 series with its polymer side links and stainless-steel crossbars, has meant customers have the maintenance free properties of an igus® e-chain®, coupled with the rigidity you would expect from a steel chain.

- Cost-effective – this is an important benefit. The igus® E4.350 e-chain® can be up to 50% more cost-effective than a steel equivalent.

- Corrosion resistant – being predominantly made from one of igus®’ self-lubricating polymers means the energy chain has a high corrosion resistance, which is turn increases the lifetime of the chain.

- In some applications in the Oil & Gas industry, weight is a pivotal factor when deciding which products to use and using an igus® energy chain could save the customer up to 40% weight vs an equivalent sized steel drag chain.

- All igus® energy chains are maintenance-free and self-lubricating, so there is no need to oil or grease them throughout their service lives. Unlike steel drag chains, which require lubrication, and in turn, additional time and money purchasing the lubrication, as well as labour costs for lubricating and maintaining the energy chains.

- All igus® energy chains are available in igumid ESD material (Electrostatic discharge) for hazardous environments. Full documentation is available on request.

- Easy assembly of e-chain® and internal separation. This is a huge advantage of an igus® energy chain. All chains are designed with ease of assembly in mind. Unlike steel chains, igus® energy chains are built from off-the-shelf component parts. For the E4.350 series, the interior separation can be built up as a sub-assembly, to ensure fast & easy assembly offshore.

- igus® energy chains can be supplied pre-populated with cables & hoses, known as an igus® readychain®. An igus® readychain® can come in various shapes and forms, from loose cables inside the chain, all the way up to cables with connectors harnessed by igus®.

- igus® also offer full turnkey installation, or installation support on all products, anywhere in the world.

There are some huge benefits to changing from steel to polymer so at the design stage talk to our engineers and see how igus® could save you time and money.