Plastic gears vs metal gears. Change up a gear!

Plastic gears vs metal gears. igus® gears offer up to 80% more wear resistance than conventional plastic.

igus® is known throughout the world for its innovation of polymers, dating back as far as the 1960’s, but until recently it has not been associated with polymer gears. This has now changed with its entry into the polymer gears market. But we get the same question from our customers “plastic gears versus metal gears? How do they compare?”

If you want to learn about how the igus® gears are manufactured: https://blog.igus.co.uk/how-are-plastic-gears-made-igus-gives-an-insight/

To find out more about plastic gears vs metal gears and the clear benefits of igus® polymers, keep reading.

There are three main points to consider:

1. Plastic gears vs metal gears. Easy configuration and NMO

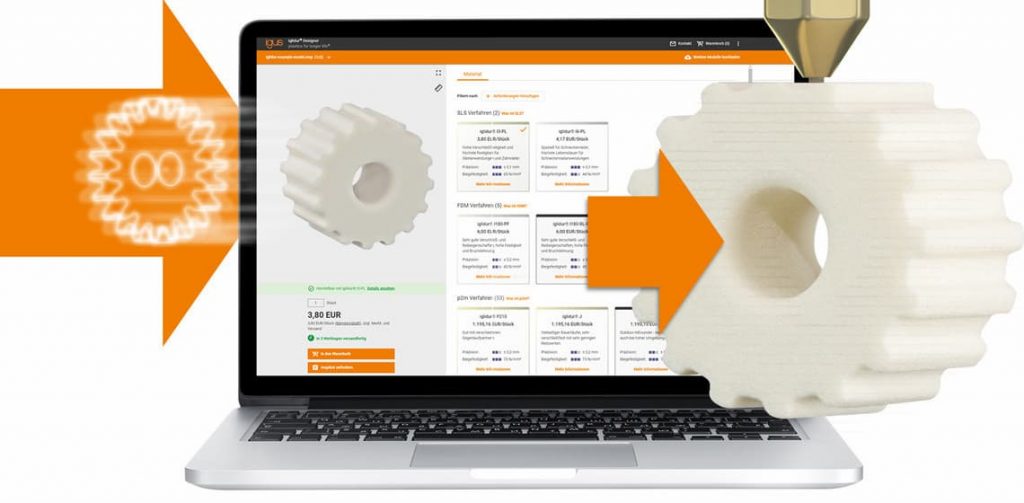

As with the majority of igus® products, we offer a free gear configurator that can create a model within 1 minute online. The beauty of this tool is you have the flexibility of picking from a range of materials, you can see the geometry of the part in 3D, and you can order an individual gear or one million, there is no minimum order quantity.

You can also download a STEP file to use in your design and a data sheet. All for free. We have always wanted to give customers the flexibility to incorporate igus® products into their designs and applications at the beginning of the process, and tools like this make it possible.

This is not something that most metal gear suppliers offer.

2. Plastic gears vs metal gears on delivery

As a society we a have become obsessed with speed. We are impatient creatures and are not organised enough, so a bit lastminute.com. But, plastic gears vs metal gears, what can get you the quickest delivery?

Luckily, 3D printed gears can be manufactured and dispatched within 72 hours, which is ideal for those time-critical jobs!

igus® also has a large range of standard injection-moulded gears in stock, so it may be that changing from metal to plastic is not as difficult as you think. Producing plastic gears is also more cost-effective, therefore, the cost to customers of plastic gears is significantly lower than metal gears.

So, referring to the early “plastic gears versus metal gears” debate, lower cost, quick delivery…. Do you still need convincing?

3. Free plastic gear engineer support

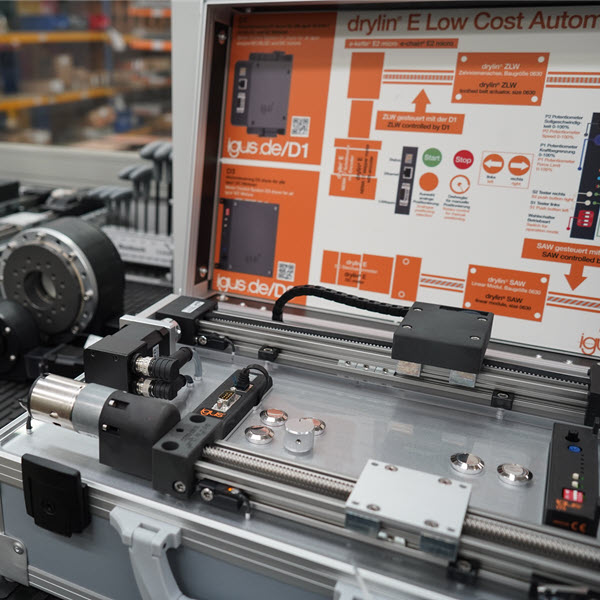

Support for customers has always been essential for igus®, another reason why the configuration and service life tools are so important for us to have available. We have engineers that cover the UK, who provide a free visiting service, no matter where you are! The engineers have an extensive working knowledge of igus® polymers and applications and if they require further support, we have product managers who will add to the knowledge bank.

Not only that, we are a subsidiary, so we have the international backing of not only our parent base in Germany, but all over the world. We have vast experience and expertise worldwide, enabling us to pool wisdom from near and far.

We offer digital consultations via email. Phone or Teams’ meetings. We also have live chat available with humans answering your questions and not robots. Can your metal gear supplier offer that?

Improve your gears now!

Times are changing, people are more aware of their options and innovations in plastics are creating controversy when it comes to the plastic versus metal debate.

But when you can get parts quickly, you can make savings, you can download CAD files into your design for free, you can increase the lifetime of your gear and you can have support from an expert team, why would you not change from a metal gear to a plastic one?