How important is smart plastics technology in automotive production?

No one likes a failure. In our own lives or in industry. Both can be catastrophic. Heart failure can shut the body down, a technical failure can shut a production line down. Obviously different levels of catastrophe; however, in automotive production, a failure can shut production lines costing tens of thousands of pounds every hour they are down.

So, how do we prevent it? And how important is smart plastics technology in automotive production?

Smart plastics technology in automotive production, is it important?

There isn’t any other industry that needs reliability more so than the automotive industry. Every part of the car build requires automation of some description, whole vehicles or individual components, such as the engines, go through production lines, with varying degrees of automation. If production stops here because of a failure, it very quickly leads to expensive losses.

This is why it is important especially for vehicle manufacturers and suppliers. The need to have fail-safe components is paramount.

How do smart plastics work?

Many automotive production companies rely on “smart plastics” from igus®.

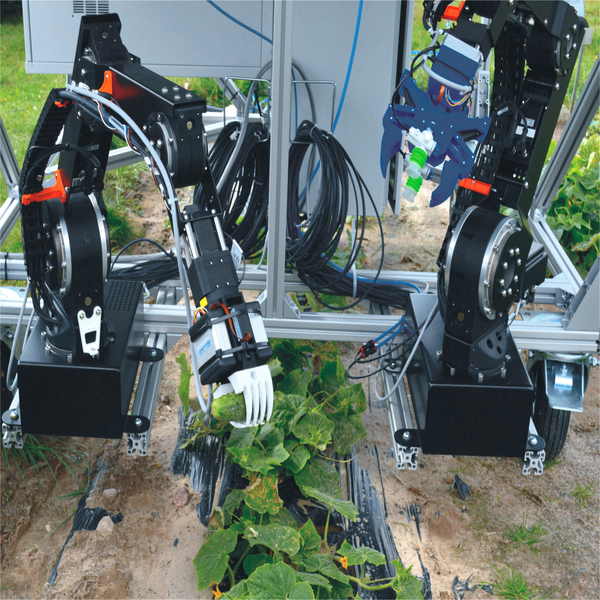

Smart plastics are intelligent solutions which monitor data on the condition of the components on the machine or production line. Sensors measure wear during operation and notify the user early enough to plan a repair or an exchange before any permanent damage is done. This can prevent failures before they occur and ensures production lines can be shut when it’s suitable and rectified cost-effectively.

In automotive production, lost production can cost tens of thousands of pounds every hour they are down to fix a failure, so having the ability to monitor the condition of the components and act before the failure is a lifesaver for the industry.

How can igus® help in automotive production?

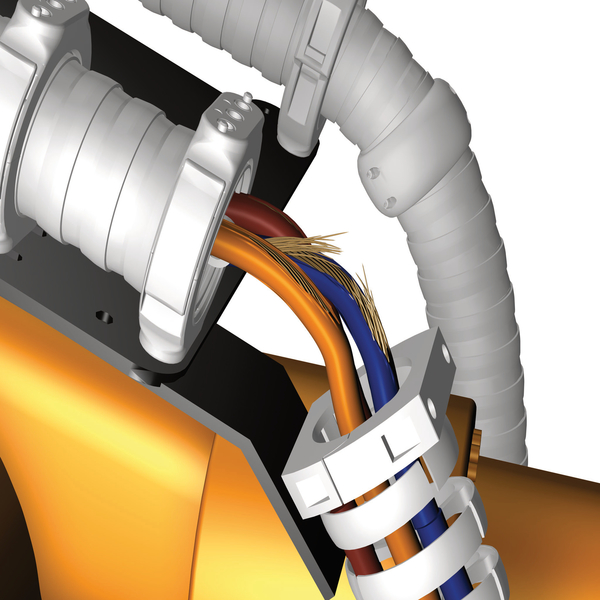

Luckily igus® identified this requirement and have now got software and hardware which can be part of the solution for preventing failures. For example, in the case of car body construction production lines, large industrial robots are used for the rotary movements. These robots can be fitted with igus® triflex® energy chains, a modular chain which protects the cables powering the robot without compromising on the movement. You can find more blogs on triflex® on industrial robots here https://blog.igus.co.uk/category/robotics/

igus® isense sensors can be mounted on robots to monitor the condition. If the triflex® energy chain breaks, there is a signal that goes back to the control box. This digital networking of machines combined with products and intelligent sensors now makes it possible to record the condition of components, ensuring the health of the machine or production line remains strong. If a breakage occurs the operator is notified as soon as replacement or repair is required.

Is it worth investing in smart plastics for automotive production?

There is a saying here at igus®: “buy cheap, buy twice” and I used to think this was nonsense, however, it is becoming more and more accurate. Sometimes you have to invest at the beginning to save costs in the long run. Investing in quality products that have years of testing and confidence behind them go a long way. This is no different to investing in smart plastics. The initial outlay might be significant, HOWEVER, if a product could then save you tens of thousands of pounds by reducing downtime, surely it is worth the investment?

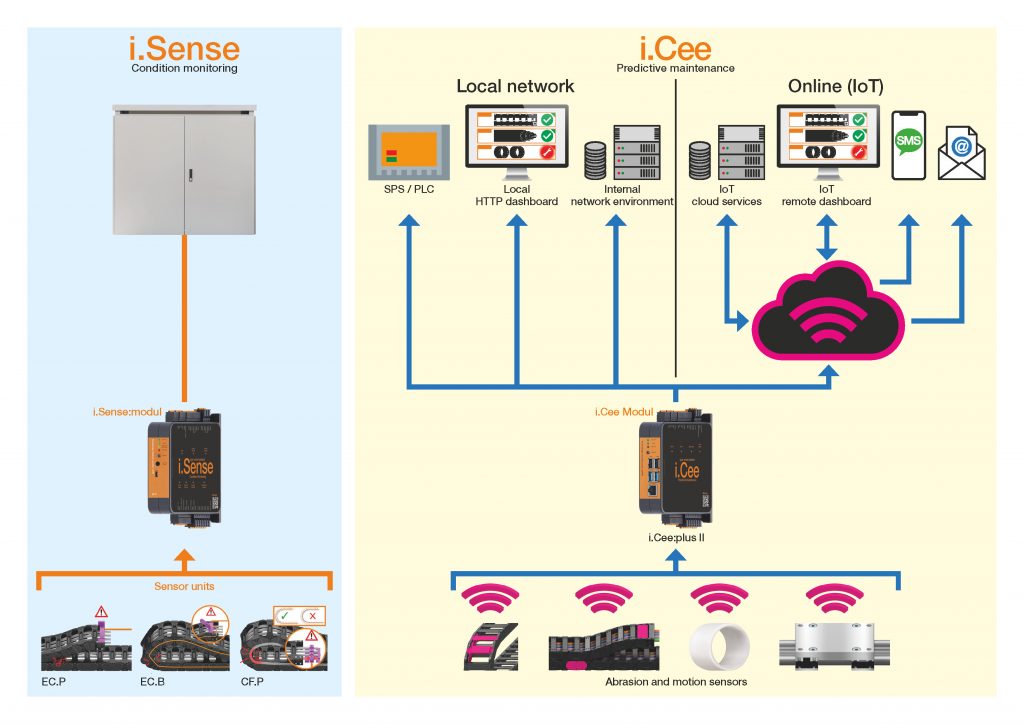

Smart software

The igus® predictive maintenance system software is called i.cee. This software combined with the special iSense sensors on either the energy chains, bearings or linear rails all help determine the wear and report back to the operator. This turns the individual components into smart components. Anything that can relate data back or can “talk” to the operator is known as intelligent or smart. It is actually really clever when you think about it. If only a human body could report a heart problem before it actually fails….