Sustainability in manufacturing

It is becoming increasingly important for companies to be aware of their responsibility to reduce their carbon footprint and prioritise sustainable practices. This post explores various strategies that manufacturers can adopt to increase their sustainability and contribute to a healthier planet.

Encouraging sustainability in your manufacturing site

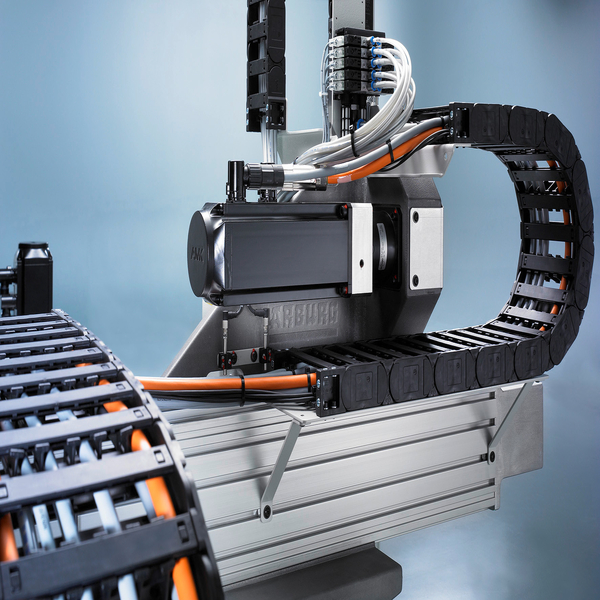

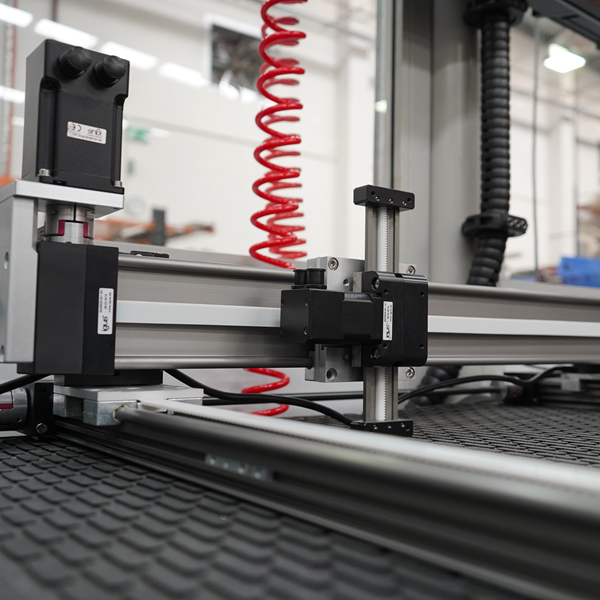

One of the most effective ways to do this is by improving energy efficiency. Whether this be through replacing old, inefficient machinery with energy-efficient alternatives or by streamlining manufacturing processes to minimise energy waste, a more sustainable manufacturing environment can involve everything from better scheduling to the use of advanced technologies like IoT and AI for predictive maintenance.

Investing in renewable energy sources such as solar or wind can also help reduce reliance on fossil fuels. Many manufacturing sites are now installing solar panels or wind turbines to generate their own clean energy. These systems often use igus® motion plastics which are ideal for use in this area:

- UV resistant

- Corrosion and lubrication-free

- Robust in dirty, dusty conditions

Take a look at some customer applications.

Reducing waste is another critical aspect of sustainability. Manufacturing sites can adopt several practices to successfully reduce this from consistent practices like a recycling program for materials like metal, plastic, and paper to finding ways to reuse by-products within the manufacturing process to further reduce waste.

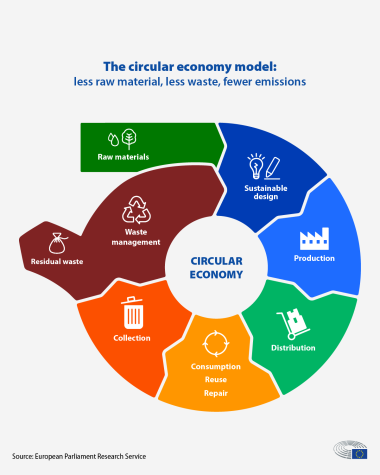

A Circular Economy

This is something we have discussed on the blog before as it is an important model of production and consumption where products are designed for reuse, refurbishment, and recycling, which can drastically reduce waste and promote sustainability.

Read more about the circular economy.

Creating a working environment where all employees understand the importance of a circular economy allows them to contribute towards its success and communicate this to customers. Having a transparent focus on sustainable practices can strengthen customer relationships and encourage new customers who value green businesses.

Encouraging a culture that values sustainability increases the chances of any sustainable initiatives being successful. This could be achieved through training to highlight the importance of environmental protection, incentive programs or establishing ‘green teams’ that head sustainability initiatives and encourage employee involvement.

Potential Roadblocks

- High Initial Costs: Implementing sustainable practices often requires upfront investment in new technologies, equipment, and training. This can be a barrier, especially for SME’s.

- Technological Challenges: Adopting new, sustainable technologies can be complex and time-consuming. It may also require substantial research and development efforts.

- Regulatory Compliance: Keeping up with evolving environmental regulations can be challenging and costly. Ensuring compliance while maintaining cost-effectiveness is a significant hurdle.

- Resource Efficiency: Optimising the use of resources such as raw materials, energy, and reducing resource consumption requires continuous effort and innovation.

There can be challenges that prevent various businesses committing to concrete sustainable plans, but many manufacturers find that the long-term benefits outweigh the initial drawbacks.

Sustainable Product Design

Designing products with sustainability in mind is something igus® has been doing for decades. Sustainable product design involves using materials that are renewable, recyclable, or biodegradable that can reduce the environmental impact of products.

igus® motion plastic components are self-lubricating, meaning they don’t rely on any external lubrication which saves substantial time and money as well as protecting the environment from damaging chemicals.

Increasing sustainability in manufacturing sites is not just about meeting regulatory requirements or enhancing brand image; the central focus should be on making a positive impact on the planet. By adopting energy-efficient practices, reducing waste, engaging employees, and designing sustainable products, manufacturing sites can transform their processes.

The journey towards sustainability may be challenging, but the rewards for the environment, society, and businesses themselves are well worth the effort!