Conveyor solutions. Are your conveyors running on a knife edge?

Conveyor solutions and their importance are often underestimated in our world. Indirectly, conveyors keep the world moving, keep production lines running, keep breakages to a minimum and without them, the world grinds to a halt.

How to significantly increase your conveyors’ productivity

Given the importance of these conveyor solutions, we need to consider the way in which we can increase conveyors productivity. How can we make a positive impact in applications and industries? What can we do to improve systems that are working well, and make them perform even better?

Do you want to:

- reduce downtime?

- increase service life?

- save money?

In this blog, I will explain what conveyor solutions you can do this by making one small change to your application, change your metal bearings for polymer bearings.

Reduce downtime

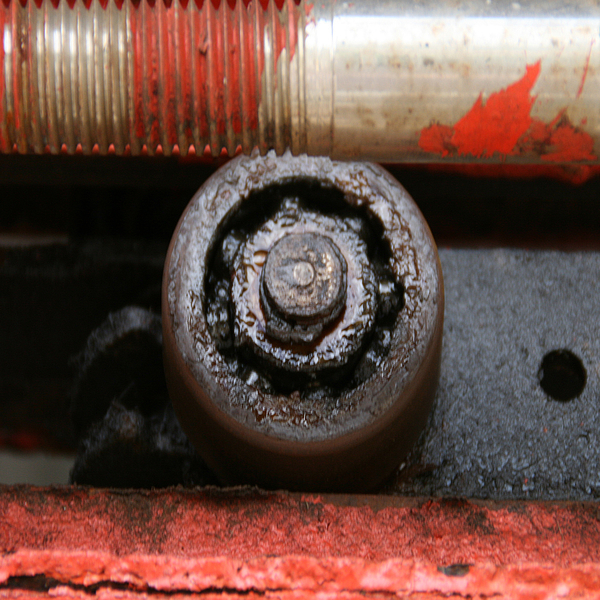

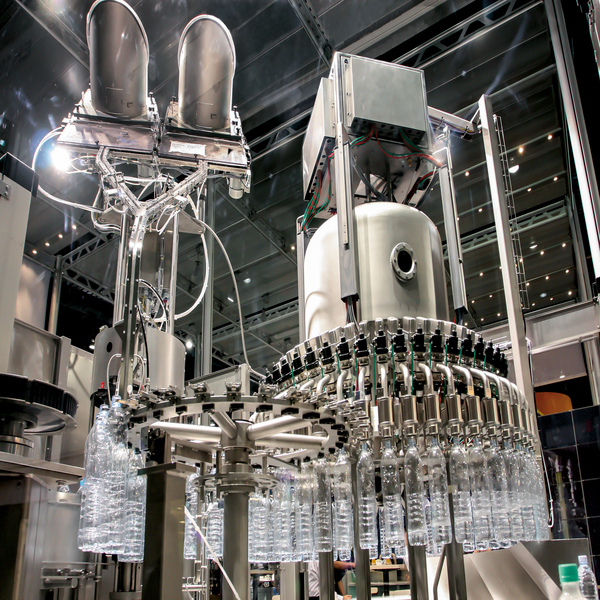

By incorporating igus® knife edge rollers into your conveyor system, these small complete polymer rollers, manufactured from our proven polymer materials, can help prevent the conveyor from wearing. Knife edge rollers can be applied into almost every industry. They are heavily used in the food and packaging industry for the transfer of:

- food produce and packaging containers between two conveyor platforms, especially in food sensitive environments

- product labelling

- warehouse product handling and transfer

By reducing wear and downtime on the machine.

Increase service life

Using igus® knife edge rollers in these environments means no contamination as they are dry running and self-lubricating. This also means that they run silently. Not requiring lubrication increases the service life of the machine or application. Dirt and dust particles do not get trapped on shafts or wearing surfaces, which allows the whole conveyor system to run smoothly. When metal runs on metal, wear is guaranteed so protecting your running services is vital to increase service life.

igus® knife edge rollers beat conventional roller materials in every aspect. The igus® polymer materials are:

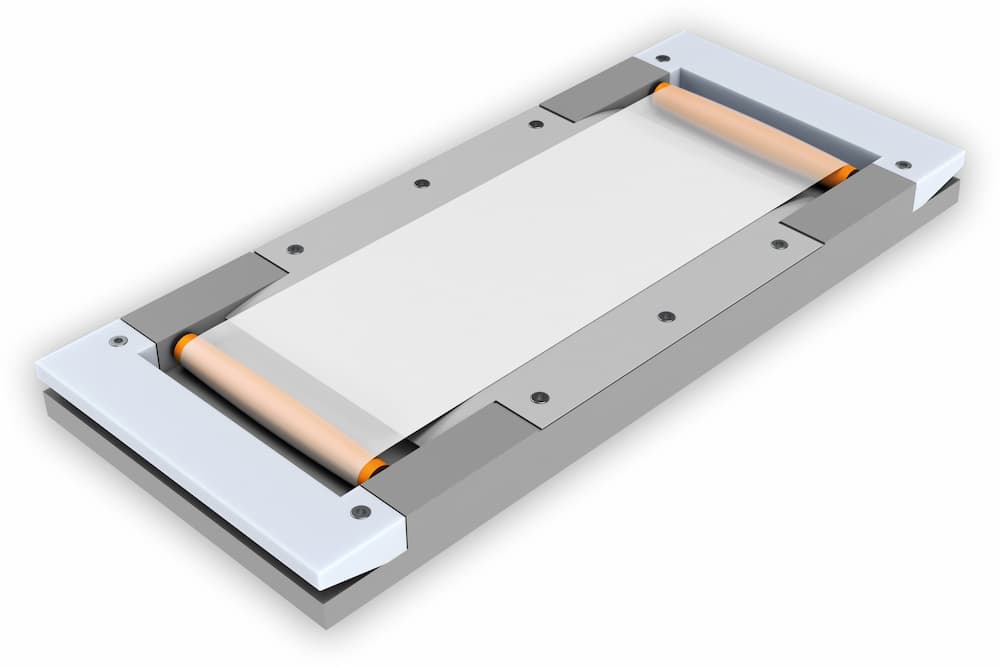

Robust and can withstand high temperatures, the new A250 knife edge roller pictured can work in long term temperatures of +90 degrees and down to -40 degrees.

Dirt Resistant, the igus® materials are tested vigorously in our dedicated test lab before they are certified for use in industry.

Hygienic, many igus® materials are certified with FDA . Corrosion-free for continued wash down cycles that withstand many chemicals.

The overall advantage of igus® polymer materials in conveyor solutions is longer lifetime and less maintenance requirements.

Would you like to learn more? Click here to read more about knife edge rollers

Save money

Taking the previous two points into consideration, it is clear to see how changing to igus® knife edge rollers can save you money, no grease is required, less maintenance, increased service life, less downtime and being polymer, they are more cost-effective to purchase. Sometimes, conventional size rollers are not required, and a custom size or shape is.

We can offer customised rollers! Custom designs are made possible from our range of 29 iglidur® materials. We can 3D print, machine, or Print to mould, all options without expensive tooling costs. Having a large range of standard rollers on the shelf, allows us to be competitive, the rollers link together to form longer bonds. However, having the ability to offer custom designs and lengths creates more opportunities to help you find a solution.

With these conveyor solutions make your conveyors more efficient and productive today!

If you have conveyors in your business, factory or part of a machine build, then please contact us for a free sample, or we can arrange for an engineer to visit you and advise on the most suitable materials for your application. Alternatively, you can read more about knife edge rollers here https://blog.igus.co.uk/?s=knife+edge+rollers