The top 3 benefits of using overhead conveyor systems

Overhead conveyor systems are underrated, and as space becomes a premium and the demands on material handling increases, companies are having to be clever with their space. It is not only space that customers are looking at being clever with. The need for cost saving and consideration for the planet are also high priorities for customers.

With this in mind, we look at the top 3 benefits of using overhead conveyor systems and how they can embrace cost saving, environmental impact and cope with space constraints. But first, what are overhead conveyor systems?

What is an overhead conveyor system?

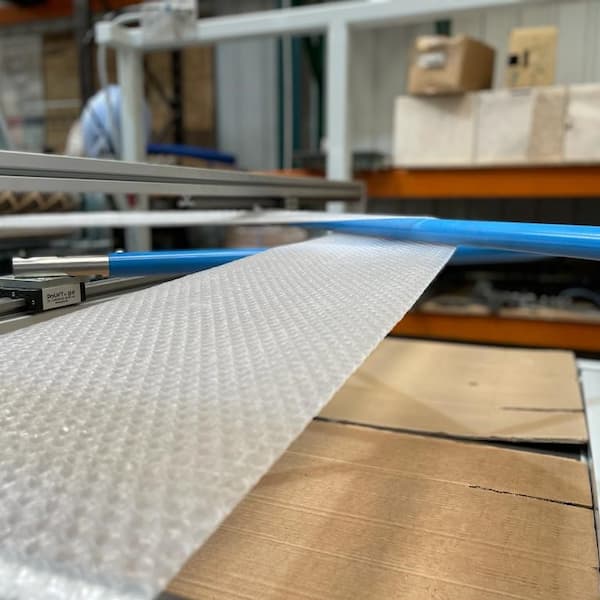

This answer is actually very simple. It is a conveyor system suspended from the ceiling which facilitates moving parts between various locations. These are usually automated and powered separately to other conveyors. There tends to be a continuous loop of track which allows the parts to be moved from various parts of the warehouse.

Benefit number 1.

Space & safety:

By utilising the ceiling space, this allows factories and warehouses to double their goods transportation. This is an efficient, space optimising way of doubling the production area without doubling the square footage of the building. Limiting the physical footprint of the building ensures costs remain the same in terms of rent, it also considers the environmental impact of not needing to eat away at any natural surrounding environment.

Using overhead conveyor systems also offers a safety element in the fact that the conveyor systems are located up high, high above the heads of the employees. Why is this a safety advantage? This eliminates any chance of trips and interference between workers and the conveyor systems, helping promote employee well-being. Not only does it ensure employee safety, but it also decreases the potential for employee time off after suffering from a fall or injury.

Benefit number 2.

Cost:

The rigid track or loops allows the conveyors to run continuously, and many people are turning to igus® products thanks to their low cost, their lubrication-free properties and their availability. Despite being rigid tracks, the design is flexible and exchanging metal components for polymer ones, such as xiros® ball bearings for metallic versions. These are not only saving customers money but are offering a cleaner operation. Without the need for lubrication, this ensures that no grease or oil will fall from the ceiling.

Benefit number 3.

Cleanliness:

Following on from the above statement, the lack of lubrication required ensures no one gets coated in oil or grease from the overhead conveyor systems. This allows them to move freely without interruption as the components do not get clogged. Ensuring that nothing drips from the overhead conveyor systems is crucial.

How can igus® products help?

igus® products are known for their cleanliness and thanks to being completely lubrication-free are ideal for the overhead conveyor industry. Our range of ball bearings are used across standard conveyor systems, along with our ball bearing conveyor rollers. Utilising the technology and products already working well in these standard systems, it makes logical sense to use them in systems hanging from the ceiling.

In principle the system is the same, just elevated. The requirements are the same, a need to be lightweight and yet heavy duty. The need to be automated and low maintenance or even no maintenance. All of these elements are found in the various igus® products available for this kind of application.

Other industries and applications that use our xiros® ball bearing can be found here: https://blog.igus.co.uk/category/dry-tech/xiros/ but we are always on the lookout for exciting new innovations that can use our products.

For more information on the igus® products used in overhead conveyors visit:

https://www.igus.co.uk/info/xiros-in-overhead-conveyor-systems