What is iglidur®?

What is iglidur®?igus® has been producing highly technical plastic bearings and components manufactured from iglidur® materials for over 50 years, and they are fast becoming the ‘go to’ replacement for their metal equivalent. But what is it about these igus® materials which has made it such a popular choice for replacing not only metal but also other plastic counterparts? In fact, what makes an iglidur® polymer and why would you choose one over other traditional plastic and even metallic components?

‘What is iglidur?’ is not the only questions we have answers to, find more here

What is iglidur®?

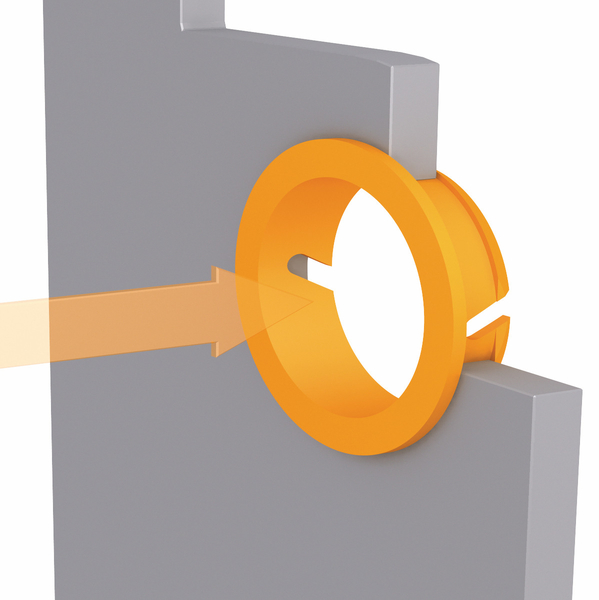

igus® developed iglidur® materials as high-performance polymers but each one has specific specialised properties that individualise themselves from the rest. All the iglidur® materials are wear-resistant, robust, self-lubricating and therefore also run completely dry. Thanks to extensive testing, igus® can confidently calculate the service life of their bearings, depending on the application parameters required by the customer.

Each iglidur® material consists of three key components; the base polymers, fibres & filling materials and solid lubricants. These three elements create a unique combination and it’s this combination of components that form the base of all the igus® materials. Every application is different. Every parameter can be different so to ensure that each application has a suitable material, additional components are added to the foundation elements to create different compositions, different iglidur® materials.

Self-lubricating

Now we’re answered ‘what is iglidur’ we begin to explain igus® materials further. Being lubrication-free has always been a unique selling point. Yet people still ask, “what lubrication can, or should I use?” What is the fascination, almost a need to lubricate parts? There is simply no requirement for any lubrication! Furthermore, the self-lubricating element also helps reduce the co-efficient of friction and helps reduce the maintenance required due to the dirt resistance caused by the self-lubrication of the materials.

Comparable to other plastics

It is a common misconception that igus® bearings are nylon bearings. Nylon is a material, just as iglidur® is a material so igus® does not sell Nylon bearings, superior alternatives to Nylon material yes, but not Nylon.

The range of iglidur® materials that are available will be comparable to other plastics. For example, we have a high-performance range of materials such as iglidur® Q2E, X, A350 and A500 and these would be suitable for most applications where there is high load, high temperatures or a chemical resistance requirement, where you may see materials such as PEEK or HPV.

iglidur® over traditional plastic

There are many benefits that iglidur® materials can bring to your application, many are mentioned above. But there are more!

- igus® is unique when it comes to calculating the life cycle of bearings. The development of the lifetime calculation programme allows customers to know how long their product is going to last and arrange planned downtime should they wish to replace bearings, well before the products are due to require replacement.

- There is also a product finder which helps you specify the most suitable material for your application. The results that these configurators provide are all based on thousands of test results carried out in our laboratory.

- If a standard option is not plausible, there is stock material in either bar or plate which can be machined into the customer design. There is also a 3D print service, tribo-coating service, fit calculators, all the tools a customer needs to find the correct igus® material for their application.

Now we have answered ‘what is iglidur®?’ and you are STILL not convinced that igus® materials are the way forward, contact us and it won’t take much for you to be convinced.