What is powder coating ?

What is powder coating and how is this related to igus®? Good question.

What is powder coating ?

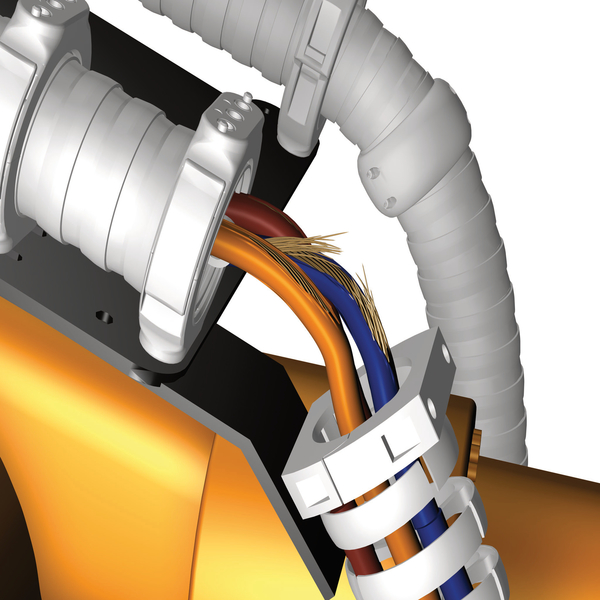

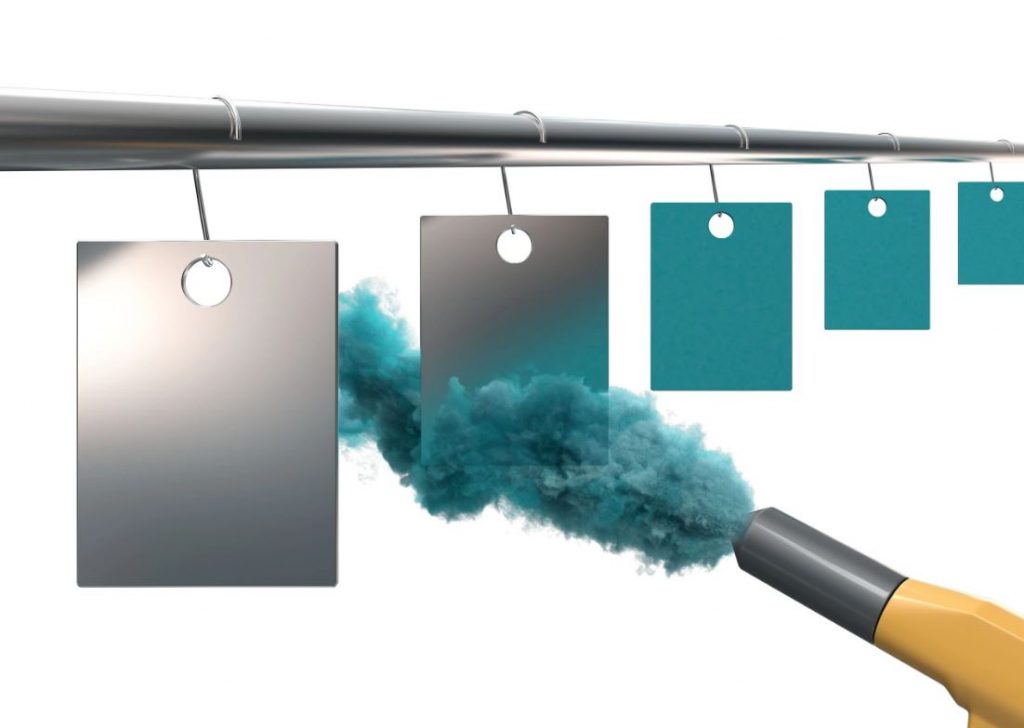

Powder coating is a process where a powder material is applied to an object, normally by heating the object, applying an electrical charge and spraying the powder on with a gun to protect the object from wear. The material builds up in layers and adheres to the component, which is normally a metallic object and is cured during a heat process, The powder coating process can also be known as powder lacquering, which is the same process, just a different name.

What are the advantages of power coating ?

There are many reasons why people chose to powder coat parts within machines, such as;

- Space restrictions and accessibility

- Cost-saving

- Speed.

- Thicker coating than paint

- Environmentally safer.

When it comes to space restrictions, powder coating is ideal. By spraying the material onto the components, it allows the covering to reach the smallest spaces. The standard layer thickness is between 60 and 120 μm you are not restricted to this thickness. Depending on the geometry and substrate, the thickness can be applied up to 500 μm.

Everyone requires environmentally safe options for everything nowadays, quite rightly so and powder coating materials are more environmentally friendly than other forms of coating. This is down to the fact that no solvents are released into the atmosphere as the coatings do not contain solvents.

Powder coating tends to offer a greater durability to that of other coatings, so on components subject to wear this is ideal. This also goes hand in hand with the ethos of igus®, plastics for longer life.

Do igus® offer powder coating materials?

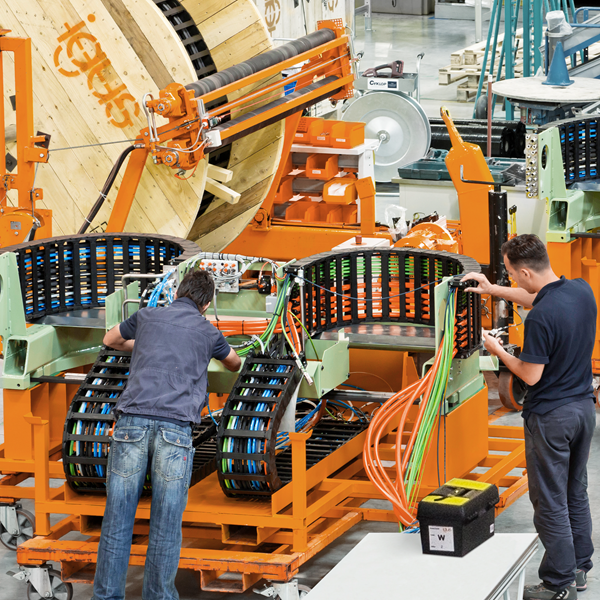

igus® could see the potential for having the self-lubricating materials that are traditionally moulded and extruded produced in powder form and therefore created 7 high-performance polymer powders. To ensure we could cater for several industries and applications, we developed and released various materials such as a high temperature version; IC-04, food approved; IC-05 and a high chemical version; IC-07.

These materials are sold as powder in 1kg, 2kg or 10kg bags, allowing individuals to powder coat their parts on site. Alternatively, igus® offer a coating service so customers can send in their parts and we will get them treated in whatever material is required.

Are their any disadvantages of powder coating?

There have been reports of a slight change in colour once the parts have been cured however this is insignificant in the case of the igus® powders as they are generally not used for aesthetics.

The only other slight disadvantage is preparing the surface of the part being coated. These need to very clean and dry for the powder to adhere to.

What applications would you use powder coating for?

The options for applications and industries for powder coating are endless. We have had many successes with packaging machines, venetian blinds, mounting poles and even office chairs. These successes have led to other areas being investigated where powder coating might help with wear issues.

We recently worked with Doel Engineering, a UK customer who wanted to try powder coating for their packaging machines, you can read the success story here https://blog.igus.co.uk/igus-and-doel-engineering-working-together/

The future of powder coating

So, hopefully you will have an understanding as to what is powder coating which is good as it is going to continue to grow, not only at igus® but across the board. The advantages far outweigh the disadvantages and with powder coating materials suitable for nearly every application and industry, this form of wear protection is going to go from strength to strength.