When is an e-chain® a beam?

Understanding that energy chains are actually beams, makes the physics of these chains a lot easier to comprehend.

There are 3 main examples of beams; simply supported, cantilever and strut. These can be found in everyday life and not always in the most obvious of places. Understanding the foundation mechanics of a beam is essential to be able to understand how it adapts to forces, environments and the loads that e-chains® can endure.

What is a simply supported beam?

A simply supported beam is just that. It is a beam which is supported at 2 points.

Camber; what is it?

Camber is a term which refers to the upward curve that you might find in beams and e-chains® are no exception. Camber allows additional load to be applied along the unsupported length. It also can increase service life. In e-chains®, camber is referred to in terms of FLG, FLB and C. These symbols equate to the following: Camber is a term which refers to the upward curve that you might find in beams and e-chains® are no exception. Camber allows additional load to be applied along the unsupported length. It also can increase service life.

- FLG – unsupported e-chain® with straight upper run. This is the ideal condition for energy chains.

- FLB – unsupported e-chain® with permitted sag. This is slightly bent so may have some restrictions regarding speeds and acceleration.

- C- critical sag! An energy chain should not be operated in this condition!

What can igus® offer if the system installed is showing signs of critical sag application?

If faced with a chain which is showing signs of critical sag, there are at least 3 options to consider correcting it. The first option would be to see if a deeper chain could be used. Another option would be to consider if the chains could be separated into 2 opposing e-chains®. The third option would be to change the mode of operation of the e-chain® to become a gliding application.

When is camber not required?

There are applications where camber is not required or is even unhelpful, such as vertical hanging and vertical standing applications. If camber is present on applications where energy chains are in these orientations, it can cause what is known as tear dropping. The term “tear dropping” became established due to the shape the chain takes when excessive force is applied. This force can make the chain buckle and disform, thus creating the tear drop shape and can potentially cause an over balance, or jamming if in a confined space

How do we prevent “tear-dropping”?

To eliminate tear dropping igus® offers an NC e-chain®. The NC stands for “No Camber”. This is achieved by either rotating the links of the e-chain® (some links are designed to remove camber upon rotation) or through an annealing process. Annealing is when the parts are warmed in an oven, then weighted down and cooled at a slow rate. This removes the stress in the chain, therefore removing the camber.

So how and why do you make beams deeper rather than wider?

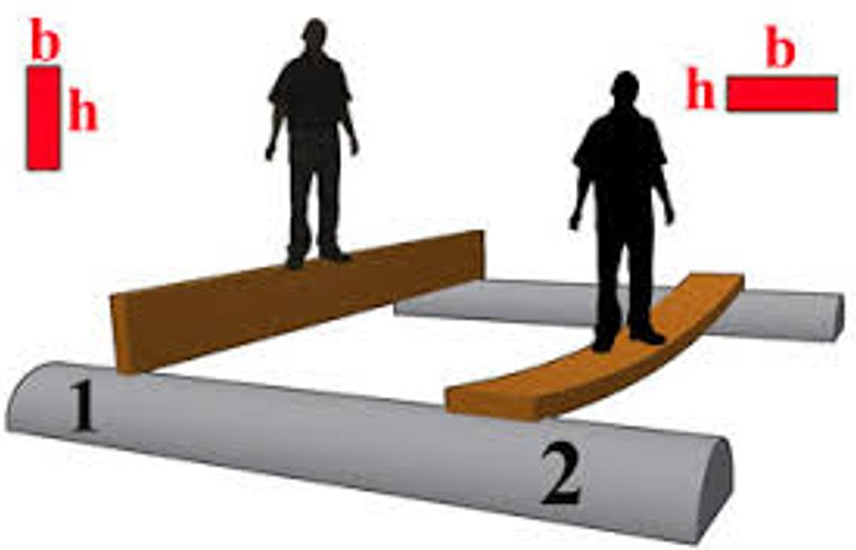

Rather than give a physics lesson on b x d³, a simple analogy is much easier to comprehend.

For example: take 2 bricks and lie them side by side spaced apart. Balance a ruler between them like a bridge. If you place a force in the middle of that ruler, it bends and ultimately could snap under the stress of the force. If you turn the ruler on its side and attempt the same experiment, you would do well to get it to bend, let alone break! By exchanging a shallower e-chain® for a deeper one, this increases the load that the beam or chain can carry without bending.

Imagining energy chains as beams makes them much easier to understand, and to see them as support as well as protection and guidance for cables and hoses.