Why do we need energy chains in engineering applications?

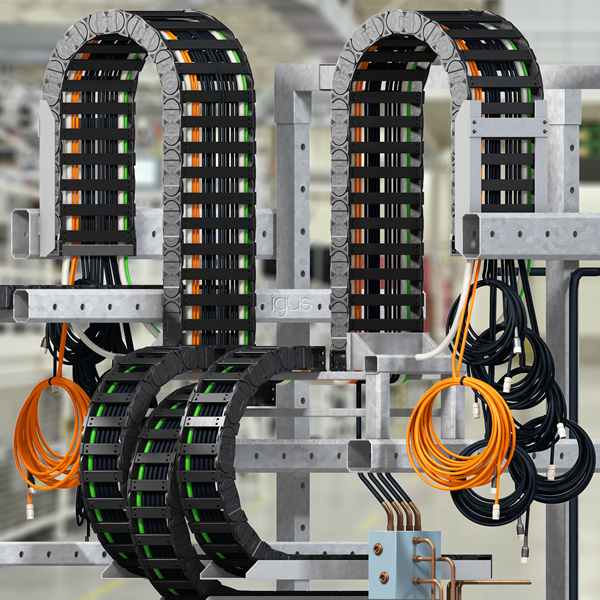

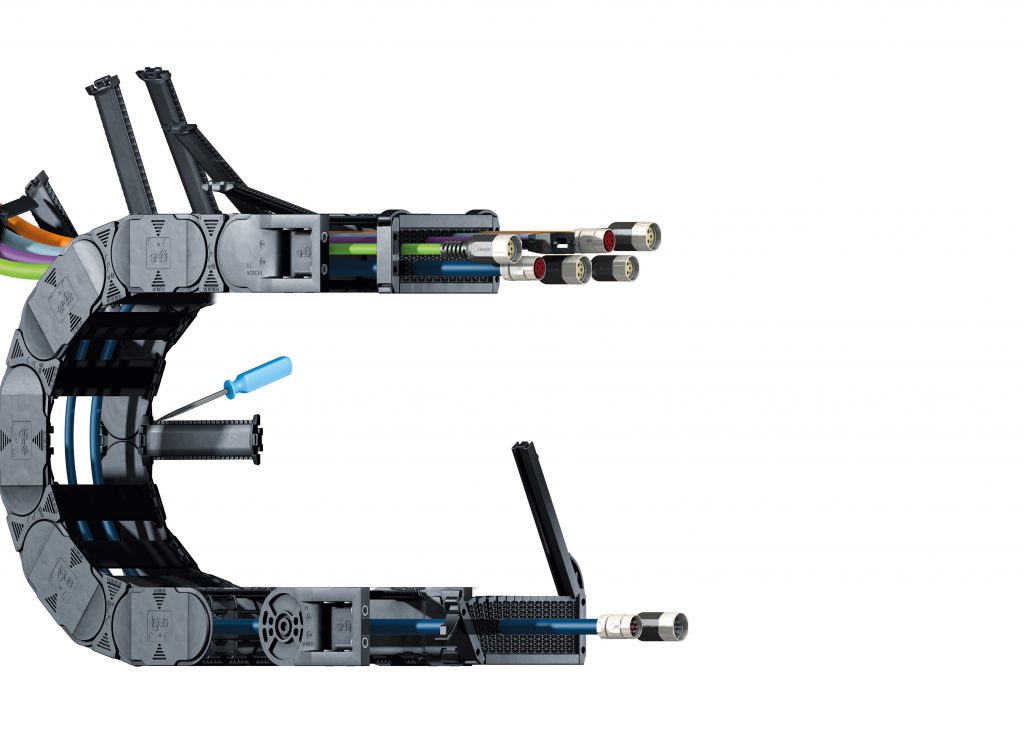

Energy chains are often called by other names, such as drag chains and cable carriers. Fundamentally this is what they are. These chain systems are designed to guide and protect cables and hoses carrying energy, data and liquid safely. The goal is to ensure an uninterrupted supply.

Many moving parts within a machine need to have a power source supplied to them. This means there will be cables connecting the power source to the component. These cables need to be protected. Why spend money on a product for your machine without ensuring it is going to run as efficiently as it can?

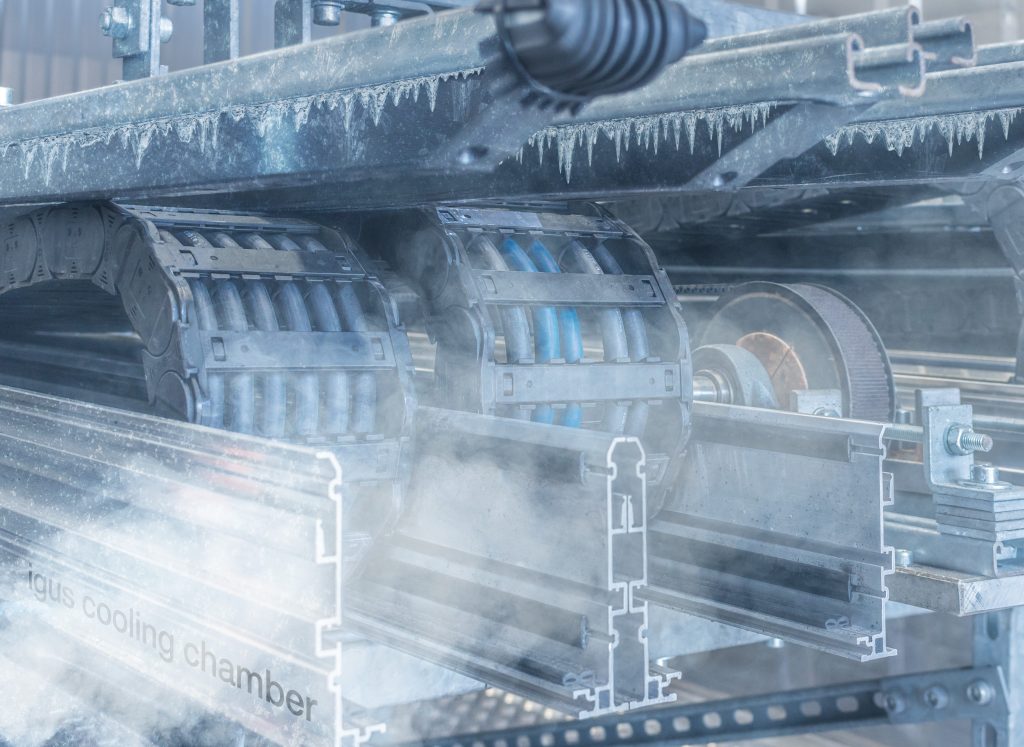

But these chains have to be able to do more than that. They must be able to withstand harsh environments, extreme temperatures, a whole range of diverse environmental influences and how many energy chain systems can cater for all these diversities?

igus® energy chains, or e-chains® as they are referred to in the igus® world, have been designed in optimised tribological materials which ensures that the maximum operating lifetime is achieved.

The range of sizes, widths and materials available enables us to be able to offer energy chain systems for most applications and allows us to be able to replace metal drag chains for plastic versions.

The metal v plastic debate

There is still a stigma surrounding plastic e-chains®; will they be able to cope in the extreme weather? Can they survive in adverse environments will plastic be able to hold the weights required?

This misconception is simply that, a misconception. igus® have invested a lot of time and resources into ensuring that the polymer chains produced are thoroughly tested and proven in all possible applications. There is a designated testing laboratory at igus® Cologne which is running 24 hours a day. This is continually testing a multitude of variants.

We have energy chains made from specific materials especially for certain industries. These range from the e-skin®; suitable for cleanroom environments and conductive ESD e-chains® for explosive environments.

“Talking” technology

There are also other unique features to igus® energy chains. We have industry 4.0 intelligent chains. Tis technology reports wear or damage back to the control system before it becomes detrimental to the application or machine. This conditioning monitoring system increases safety in machine efficiency due to the regular wear detection.

We offer a 36-month guarantee or 10 million strokes, whichever comes first. This is offered with all energy chains, proving the confidence we have in the products.

We have free online configurators which allows customers to have confidence in the chain system you pick. You have control over the parameters you enter. Another online tool we offer is the 3D CAD portal. Here you can find CAD files to help you incorporate these energy chains into your designs.

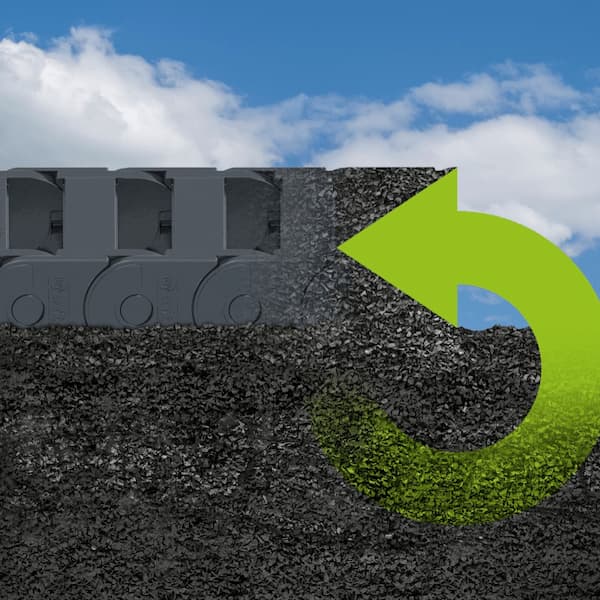

These essential energy chains can also be recycled! So even after you may consider them to be at the end of their life cycle, you can send them back to igus® in exchange for a voucher. These will be re-granulated into more energy chains! This is only a small element of their sustainability. Even producing these chains has a more positive impact on the environment. You can read more about how in this blog https://blog.igus.co.uk/the-unnecessary-plastic-pollution-how-can-we-play-a-part/

There are more positive reasons to ensure you are using igus® e-chains® in your application . However if you need convincing further visit the new e-chain® product page.

Industries that e-chains® are commonly used in are agricultural, automotive, material handling, cranes, packaging and Robotics.