Why is 3d printing important?

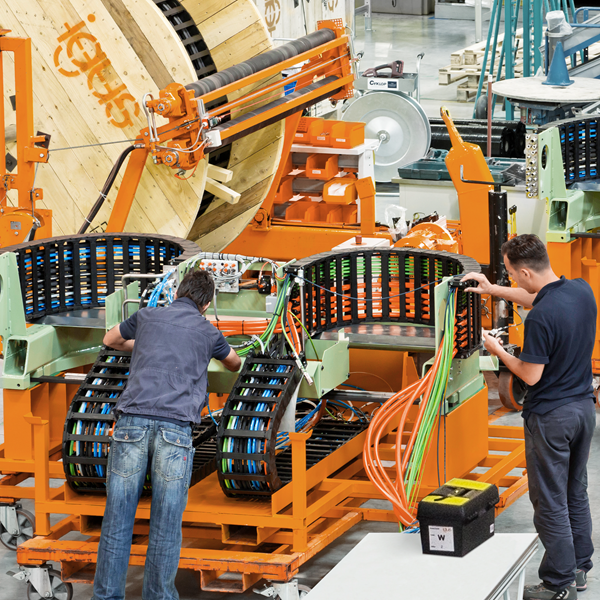

Why is 3d printing important and why choose igus® 3D print service over machining from bar stock?

The 3D print service at igus® offers a zero waste guarantee. Every section of your bespoke-made part is either fused together or laser sintered to ensure no material is wasted, and no excess is needed to achieve the end result. The magic all happens in our ‘build room’, and this is where a carefully organised operation occurs where reusing of materials, efficiency, and cleanliness are key factors. The SLS chamber might even have materials pass through again to ensure no wastage occurs, and that the process remains as clean as possible.

Why is 3d printing important?

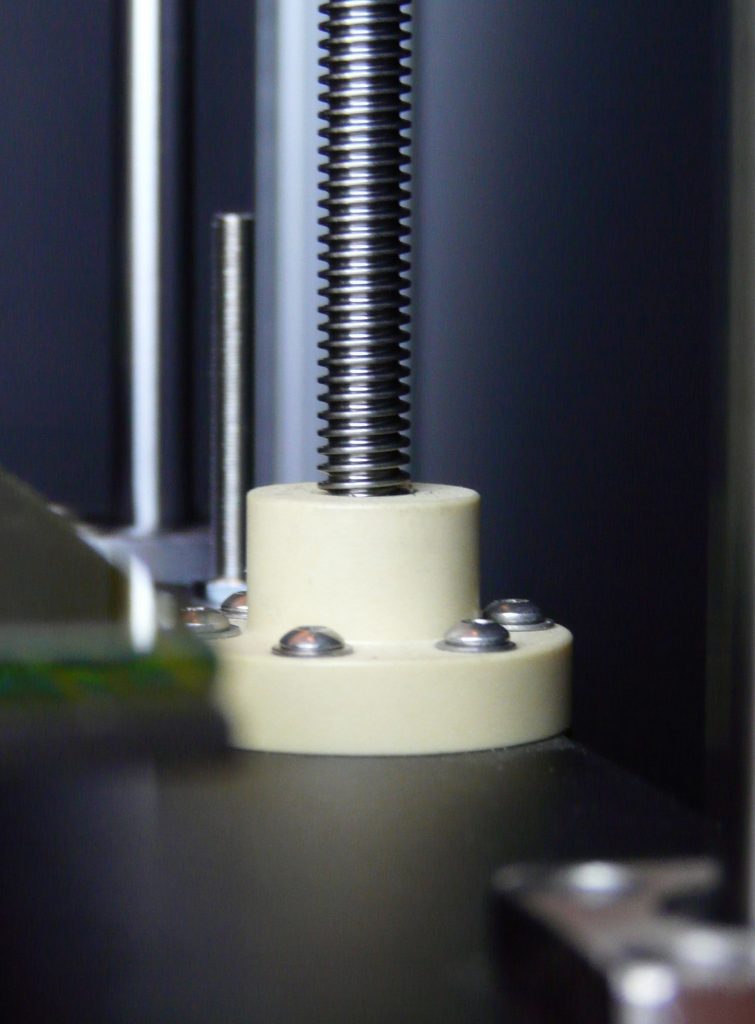

The proof is certainly in the pudding. With printed parts surpassing machined and moulded parts when tested for strength, the wear and abrasion resistance is up to 50 times higher than for standard materials. Supplied in filaments, or in SLS powders, igus® will cater for all your needs and we will assist you when you are unsure of which material and printing method to use for your application. The igus® materials are tested against not only competitors’ products but also our own materials so that the right one can be found for you.

Other properties highlighted in these tests include long service life, low coefficient of friction and high surface speed capacity. This makes them unique and a desirable alternative to machine polymers and metal substitutes.

Another consideration to look at for why is 3d printing important is the cost. The cost is considerably reduced when choosing 3D print over bar stock machining, due to the minimised wastage and system setup times. By keeping time down and being exempt from waste, igus® can remove unnecessary costs that inevitably arise when using plastic rods to machine your special low-friction bearings and parts.

What’s more, the igus® 3D print service is so easy to use that you can simply upload your STEP file to the website, configure the part, and receive a quotation instantly.

For lead screw nuts, threads larger than M6 can be printed and can be further specified for trapezoidal and special high helix threads. This reduces the lengthy process of waiting for thread cutting tools, which can often result in undesired expense. It is evident that precision is drastically increased when comparing moulding to printing, yet further intricacies can be accounted for when using 3D print which would not be possible if machining the parts instead.

You can select which igus® print filament or igus® SLS material you require, specific to your application properties: should you require the material to fit low coefficient of friction, high temperatures or low absorption properties. The parts can also then be dyed according to your visual requirements. After ordering, the subsequent delivery process is quick and easy to suit your time-precious schedule – usually within 24hrs of ordering depending on the part’s complexity.

Visit the website to find out more about igus® 3D Print.

Alternatively, contact our Product Manager Dean Aylott: daylott@igus.co.uk for any 3D Print enquiries and for other blogs relating to 3d printing visit