Benefits of industry 4.0 in manufacturing

Industry 4.0 is revolutionising manufacturing with integration of advanced technologies like automation and artificial intelligence. Sometimes called the Fourth Industrial Revolution or Industrial Revolution 4.0, the term refers to the step change happening right now in industry, which transforms how we produce, manufacture, test and distribute products through the application of technological advancements. Many of the biggest organisations such as Siemens are at the forefront of these developments.

So how exactly does industry 4.0 benefit manufacturers?

In this new age, time is a critical resource in every industry, especially so in manufacturing. Industry 4.0 boosts efficiency and productivity through automation, optimising workflows, and reducing cycle times. Tasks once time consuming and labour intensive are now automated, freeing up human resources for more challenging and strategic tasks. This streamlining results in increased output with fewer resources, (more money LESS problems) a manufacturing no brainer!

This is not to say that Industry 4.0 is easy, with factors such as steep initial investment costs and workforce displacement acting as a deterrent to many, but if utilised effectively manufacturers are likely to recoup their investment quickly, and capable, dedicated employees can work cohesively alongside these changes and even use them to minimise their own workload.

How igus® fits into this

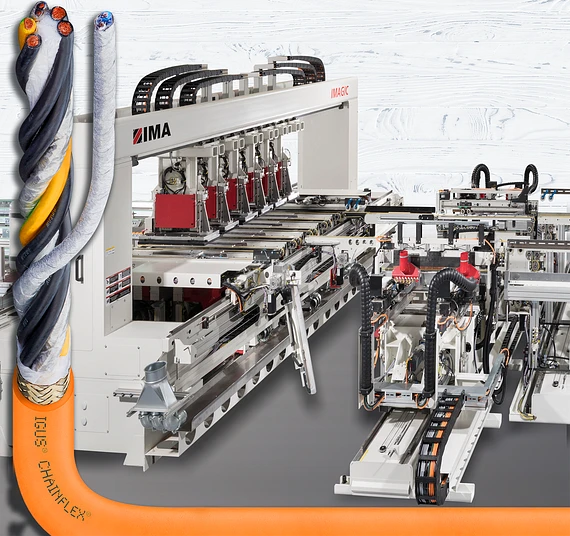

igus® is dedicated to supporting industry 4.0 and are proud to be known for an innovative approach to engineering with motion plastics that benefit virtually all industries. The standard ranges of plastic products such as energy chain systems, chainflex® cables and plastic bearings, equipped with connectivity and sensors, are known as smart plastics and are used to pursue the goal of making complex automation solutions compatible with Industry 4.0. These allow other manufacturers to upgrade their processes and pave the way to being a reliable part of industry 4.0.

From collaborative robots (Cobots) that enable safe and reliable interaction between humans and robots, to customization and digitisation that offers customisable solutions tailored to the specific needs of an industry. Just two of many revolutionary aspects at igus® that could benefit the manufacturing industry.

The future of industry 4.0 holds enormous potential for further innovation and transformation throughout various sectors. Sustainable manufacturing has become an increasingly important topic of discussion, especially in light of the negative opinion on plastics, driven by the disposal of single use plastics which does not reflect the way in which igus® use plastic material as it is used with the intention of creating products and processes with a longer life.

To read more about our ground-breaking products click here.

Our contribution to a green future

igus® ensures environmentally conscious decisions are a core element of the business, purchasing green electricity for the manufacturing plant and recycling both in office and within the manufacturing process. The aim is for the factory to be CO2 neutral by 2025! Take a look here at the steps being taken to be sustainable. Industry 4.0 technologies will play an important role in advancing sustainability goals and promoting environmentally conscious processes by optimising energy and resource usage, simultaneously reducing waste and emissions, paving the way for more eco-friendly production processes to take centre stage.

What it all boils down to…

An important focus that is at the centre of any industry is the opportunity to provide an enhanced customer experience. Industry 4.0 enables manufacturers to personalise products and services that meet each individual customers’ needs. By leveraging data analytics and digital technologies, insight into customer behaviour and preference can be gathered to improve systems that under perform and home in on areas of success.

Therefore, Industry 4.0 offers many benefits to manufacturing (a large majority of which igus® can facilitate) from enhanced efficiency, real-time data insights and customization, to improved quality control and optimized supply chains. Embracing this technological shift enables manufacturers to stay competitive and innovative in the digital age. By incorporating this into an open-minded business now, the path to becoming a business fully submersed and comfortable within industry 4.0 draws closer, a significant competitive advantage!