What does the UK manufacture?

There has been an uptick in the amount of UK manufacturers reshoring parts of their operations as a result of increased economic pressure.

Many people aren’t aware of just how much is manufactured in the UK. The UK has a diverse manufacturing sector from military equipment to pharmaceutical products and electronics and we remain the ninth largest manufacturing nation in the world. (MAKE UK)

The Engineer gave insight into the statistics to back up this trend in reshoring: “A remarkable 58 per cent of manufacturers are reshoring their operations, spurred on by tech advancements and the opportunity of having greater security within their supply chains, without the hefty price tag which used to be associated with onshore production.” (Source)

What is reshoring?

Reshoring involves returning the production and manufacture of goods to the country in which a company was founded, for example, the UK. It’s beneficial to the UK to localise operations and create job opportunities as a result. Increasing job opportunities minimises unemployment and helps to boost the economy. The quality of a business’ products or services could see improvement too.

When operations are taken offshore it’s much harder to monitor quality control and the quality of the product can slip as a result. This is why it is so important to trust and clearly communicate with those in charge abroad to prevent an inconsistent brand image being portrayed to your customers.

What is offshoring?

The BBC Business news article ‘Why firms are bringing their manufacturing back home’ remembers the rise in popularity for offshoring in the 1990’s as a ‘major economic movement’ where people capitalised on the opportunity to manufacture their products cheaply abroad where workers were underpaid and often overworked.

‘The result was a Chinese manufacturing boom, and a long supply chain from Europe and the US to China and beyond.’ (BBC News)

Offshoring comes with its risks from decreased quality to longer delivery times that could be make or break for customers used to a business’ way of functioning. Relationships could suffer from such a drastic change as a result.

Decision time for UK manufacturers

Each manufacturer has their own complex and varied reasoning for the shift to reshoring their operations but factors such as financial status, associated risks and the political landscape are the main contenders.

A large amount of business decisions are based around finances, whether that be risk focussed or profit focussed metrics. Offshoring became an attractive option as it was significantly cheaper due to inexpensive labour but as technology has advanced, the need to be responsive and flexible has greatly increased, something that is much more difficult to stay on top of when your operations are located abroad.

What do igus® UK manufacture?

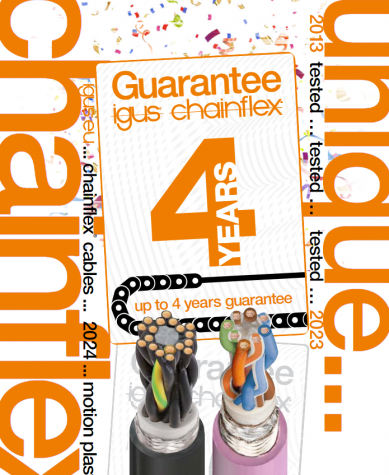

igus® manufacture harnessed cables in the UK and offer around 6000 motor, servo, signal and encoder cables suitable for 38 manufacturer standards. igus® focus on cost-effective, quality products and so we are the only manufacturer to offer a guarantee of up to 4 years or 10 million strokes for our cables.

Harnessed cables are essentially pre-assembled cables designed to meet specific customer requirements. In complex applications like vehicles, being able to organise multiple wires into a compact and flexible bundle increases the service life and safety of the product and makes installation far easier.

We also offer the readycable configurator which allows you to find the cable best suited to your application or find replacements for your current cables. The service life calculator within the configurator then allows you to see how long our product will last in your machine, helping you to make an informed decision before you buy.