Offshore maintenance – How can igus® support you?

What is the Offshore industry?

The offshore industry covers operations located away from the coastline, in open waters. The exploration, production of natural resources found out at sea such as oil, gas and wind energy create the need for applications like oil rigs, ships and wind turbines to procure and transport what we source to be used on land.

The task of extracting oil and gas is no small feat. Sometimes accommodating hundreds of people at a time, oil rigs vary in size. When fixed to the ground in relatively shallow waters, they are known as jack-rigs but for those placed particularly far from the coastline, semisubmersibles are used, floating above the water but slightly submerged to prevent the current from destabilising operations.

Once exploration and drilling are complete, production begins. To understand this process in more detail, The National Ocean Industries Association (NOIA) gives an in-depth explanation of the processes undertaken to obtain oil and gas.

Roadblocks and Solutions

As such an important industry across the world, roadblocks in the production process can have a significant impact on the ability to quickly produce such an expensive and sought after resource. Without oil and gas, it would currently be impossible to meet global energy needs. A big cost in the offshore industry is downtime for maintenance, both planned and unplanned.

To avoid unplanned downtime in offshore applications, oil rig maintenance is undertaken. An SPS (Special Periodic Survey) reactivation involves 5 yearly re-certification of drilling and other equipment to get ahead of the curve in preventing product failure.

This method is particularly beneficial for maintaining and strengthening offshore assets like FPSOs (Floating Production Storage and Offloading units), drilling rigs, and pipelaying vessels. An assets SPS presents an opportunity for the operators to carry out preventative maintenance in a controlled environment and factor in the financial impact of downtime.

However, sometimes products fail before this SPS is undertaken, whether it be faulty components or simply low-quality products not capable of lasting as long as required. This is where igus® come in with a range of tried and tested solutions to extend the service life of these applications, as well as providing the more cost-effective option.

What applications can igus products be implemented in?

Catering for a variety of industries, igus® have an extensive range of solutions designed to improve the movement in applications. So, what applications can benefit from igus products?

- Oil rigs

- Offshore turbines, both wind and tidal

- Ships

- Subsea applications

These are just some of the areas within the offshore industry where igus® products could be found.

Our Top 3 Solutions

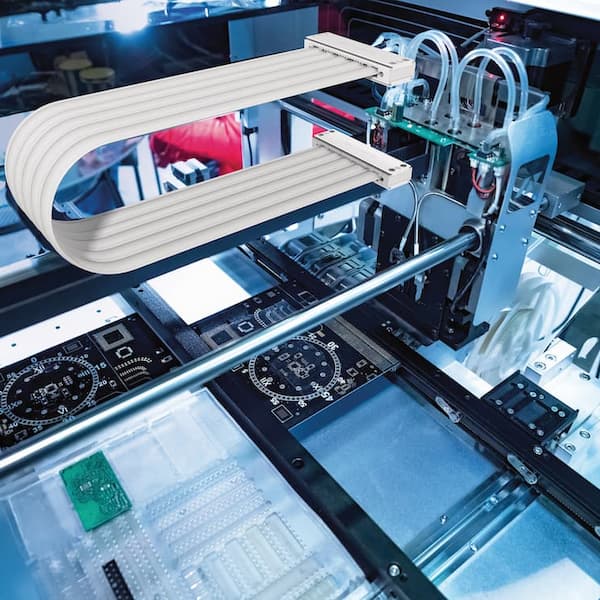

The e-loop is a cost-effective alternative to top drive service loops which allows you to remove or replace individual cables & hoses when required. The restricted bend radius allows for safe and reliable guidance of hanging cables/hoses, avoiding overbending/kinking which can be seen with conventional service loops.

The e-loop also enables the operator to combine all services inside 1 single igus e-loop, which, combined with its aerodynamic design means there is little/no movement during high winds and no tangling of different loops. All of these factors combine to dramatically reduce downtime. Oil rigs have to operate in some of the toughest weather conditions, so it is vital that the e-loop can withstand these for extended periods of time.

Take a look at one of our e-loops in action in Canada.

The igutex® bearing range, known as the toughest bearing in the world, is designed specifically for heavy loads in challenging environments such as offshore. A high strength composite fibre material, igutex® is capable of extending the service life of demanding applications and ensuring your application remains maintenance free.

Last but not least, igus® offers over 300 MUD-resistant and NEK 606 compliant cables that can be used in offshore applications and as the first company to receive DNV approval for chainflex® cables in energy chains, there is no need for time-consuming and costly special approvals.