What plastic is used in 3D printing?

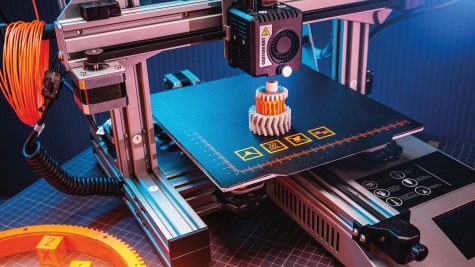

What is 3D printing? 3D printing or additive manufacturing is the process of creating three-dimensional objects from a digital file. This is done by laying down successive layers of material until the object is complete. The materials used can vary from plastics to metals and ceramics.

How does 3D printing work?

The process begins with a digital 3D model, created using computer-aided design (CAD) software. The model is then sliced into thin horizontal layers, which the 3D printer uses as a guide to build the object layer by layer. The printer deposits material precisely, solidifying each layer before adding the next.

What plastic is used in 3D printing?

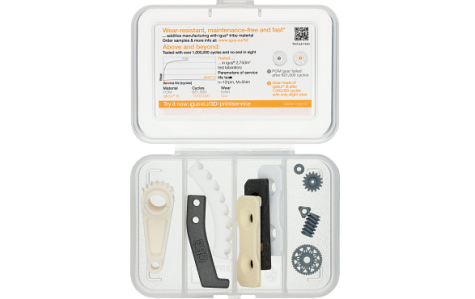

There’s a range of traditional plastics that can be used for 3D printing such as PLA, ABS and PVA. At igus®, we have our own range of filaments and laser sintering materials. This allows customers to print custom parts with wear-resistant materials which have good mechanical properties.

3D printing materials from igus® are the only filaments, powders and synthetic resins in the market that are specifically designed to counteract friction and wear. They are maintenance-free due to integrated solid lubricants and have a longer service life than conventional plastics with comparable strength to injection moulded components.

Discover our range of materials for 3D printing.

Applications of 3D printing

3D printing has a wide range of applications across various industries like prototyping and manufacturing which allows designers to quickly create and test new designs. It is also used for producing final products, especially in industries like aerospace and automotive. Other areas of application include:

Healthcare: Used for custom prosthetics, dental implants, and even bioprinting tissues and organs.

Art and Design: Artists and designers use 3D printing to create intricate sculptures, jewellery, and other creative works.

Education: It’s a powerful tool for better understanding engineering, design, and manufacturing concepts in a hands-on way.

Advantages of 3D Printing

Traditional manufacturing methods have their limitations but 3D printing allows products to be customised to meet exact requirements, no matter how complex. As well as more detailed designs, faster prototyping speeds up the design and development process, providing a more cost-effective method of production.

3D printing continues to evolve, pushing the boundaries of what is possible in manufacturing and design. Whether you’re an engineer, artist, or hobbyist, the potential of 3D printing brings many opportunities.

Why plastic?

There are many materials you can use for 3D printing so why choose plastic as your material of choice?

Our range of available products includes special filaments for 3D printing with the fused deposition modelling/fused filament fabrication method (FDM/FFF) and plastics for selective laser sintering (SLS).

Pros:

- Many plastics are easy to print with and a suitable option for beginners.

- Plastic filaments are widely available with many types and colours to choose from

- igus materials are strong and durable.

Cons:

- While some plastics are strong, they may not be able to withstand certain extreme conditions.

- The initial cost of purchasing your own 3D printer is steep, that’s why igus® can print your parts for you.

- Although there are multiple plastic options available, the range is still limited when compared to traditional manufacturing methods.

Need igus® to print wear-resistant components for you?

In our online 3D printing service, you can easily upload a CAD file and even calculate the service life for your part. We will manufacture your individual components or series from our own materials, the cost-effective and time-saving way of getting what you need.