Additive Manufacturing Production

Additive manufacturing has become indispensable in development departments, production lines, and workshops. Initially used for prototypes and view models, the technology has evolved significantly, especially in engineering plastics. Major polymer specialists have introduced 3D printing materials, enabling more functional applications. The simplicity of plant technology and handling has led to a diverse range of 3D print filaments.

igus and Additive Manufacturing

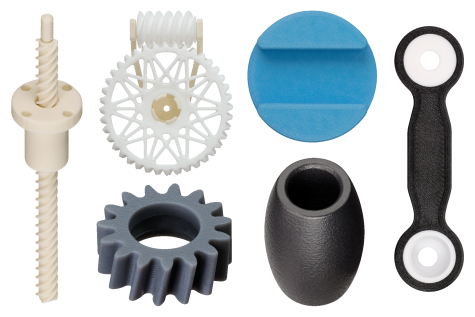

igus, known for developing functional high-performance polymers, embraced additive production years ago, creating materials for filament printers (FDM) and laser sintering printers (SLS). This article focuses on materials for moving applications where friction and wear occur, unlike static components.

Multi-Material 3D Printing

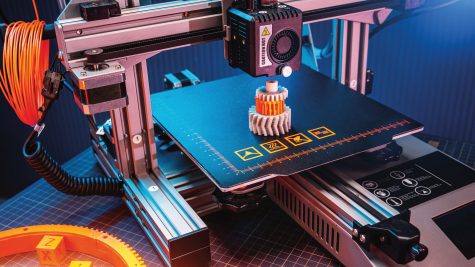

Design offices are exploring how additive manufacturing can replace or supplement existing techniques, while manufacturing technology advances rapidly. Multi-material components, or 2-component parts (2K), can be produced from two different materials in one step without subsequent joining. This is possible with 3D printers using the melt strand deposition method (FDM/FFF), where raw material filaments are applied through melting nozzles.

The 3D printer switches between materials in each layer, allowing for creative combinations. Different features like infill, outer skin, top, and bottom can be assigned to various materials using 3D printing software (Slicer).

Combination Options of Different Materials

3D printing with filament offers a variety of materials, including:

- Optics: Various colours, surface finishes (glossy, matte, translucent), metal-filled

- Mechanical Specifications: Tough, temperature-resistant, fibre-reinforced, flexible

- Special Features: Fire-retardant, antistatic or conductive, tribologically optimised, foaming

Two filaments can be combined on a standard printer, with processing temperatures being the main restriction. Materials do not need to fuse at boundary layers, as a form closure can achieve an inseparable connection.

Functional Material Combinations

Force Deflection Component: High stiffness structural material (e.g., igumid P150) combined with tribologically optimized material (e.g., iglidur tribo-filaments) for smooth, durable bearings.

Gripper Element: Fiber-reinforced filament for the body and flexible filament for gripping surfaces, providing a secure grip.

Shaft Bearings: Tribo-filaments for plain bearing elements encased with flexible filament (e.g., TPU with Shore hardness of 95 A) to compensate for angle errors and dampen shocks.

Construction for multi-material 3D Printing

To start 3D printing multi-material parts, the 3D printer must be taught where to use each material. Using Autodesk Inventor for design, a new-generation Ultimaker 3D printer with two material nozzles, and Cura slicer software, the process involves superimposing STL models with matching coordinate systems and origins.

Designing a component with several solid bodies ensures neat fitting without overlap. Exporting these as individual STL files allows for proper superimposition in Cura. The graphic shows how different filaments are assigned to models and combined into one component.

Connections between materials can be made with positive fit and material bonding. Positive-locking connections offer greater security against failure. Examples include dovetail joints and encapsulation. Cura’s slicing process alternates materials in each layer, interlocking phases and strengthening bonding.

Practical Example

A lead screw support block with a fibre-reinforced main body and tribo-filament bearing surface demonstrates practical application. The bearing surface includes a concealed circumferential element for form-fitting connection.

Multi-material 3D printing offers numerous possibilities for functional and profitable applications. If you have ideas but lack the appropriate 3D printer, igus can help with implementation. They currently process carbon fibre-reinforced filament with high stiffness and flexible filament with Shore hardness of 95 A.

To find out more on the topic of 3D printing click here.