How to construct and assemble a spindle motor.

How do you construct and assemble a spindle motor? igus® is a well-known manufacturer of technical plastics, and this is established in the minds of the mechanical engineering world. With over 10,000 core products, igus® is continually developing new products. One of them is the spindle motor which, as the name suggests, consists of a spindle, a stepper motor and a nut ! It was easier to market as a spindle motor! One of the most frequently asked questions when it comes to this product is “How easy is it to construct and assemble a spindle motor?“

So, let’s look at how easy it is!

What is a spindle motor?

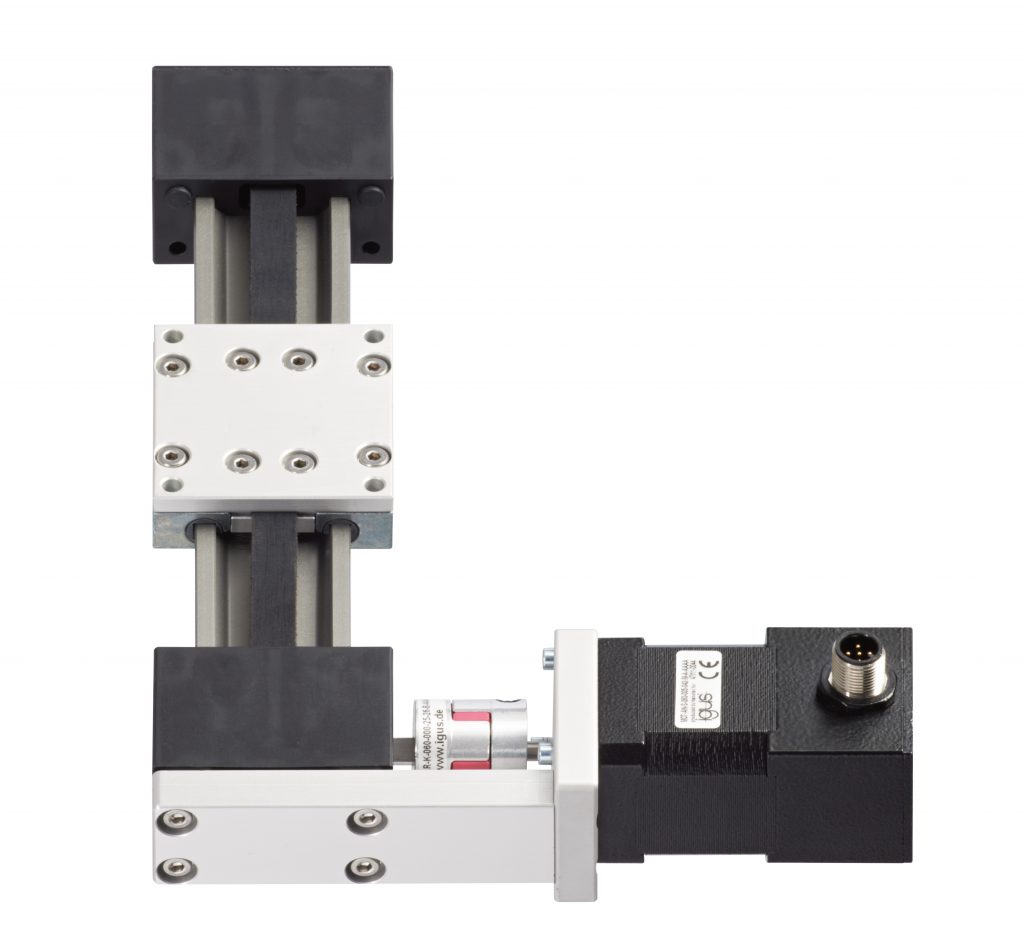

In its simplest form, an igus® spindle motor consists of a spindle, a driven nut and a motor.

These motors are specially designed to accept axial forces. We have combined our spindles with motors that can withstand the loads and speeds of various applications. Our NEMA23 spindle motor can, for example, take up 500 N axially. Some conventional stepper motors would be damaged by this axial load.

The spindle motor system is constructed with hollow shaft, acting as a holder for our spindles. This allows the system to be assembled and correctly fixed. This connection is so strong that it can only be released with a special tool and a specially developed process.

The motor can also be equipped with an encoder and/or an industrial M8 connector. The spindle is also specially machined for this motor so that the thread starts directly from the motor flange. There is therefore no loss of stroke. We also have options to modify spindles to suit customers design at the opposite end of the motor.

Find the right spindle.

This is easier than you may think.

If you have the basic information for your application, such as load, speed, orientation and any specific environmental considerations that could have an effect on the products, the spindle can be easily specified. Once this information has been input, our configurator can advise on the most appropriate spindle for the exact task. This will also advise you of the correct nut for the application. Simple.

Based on the above spindle nut selection we can ascertain the right spindle motor combination for the torque and speed required for the application.

Looking at the big picture.

As mentioned earlier, environmental factors and application parameters are essential in order to ensure the correct system is selected.

Depending on the application, the environment of the machine will determine if there are any specifics required for the system. Chemical washdowns, extreme temperatures and high loads are aspects that will affect the system, so certain elements might need to be tweaked to ensure they are fit for purpose.

Just a side note, there are many variations of how spindle motors are referred to, such as leadscrew motors and linear actuators but essentially, they are all similar products.

It’s time to assemble a spindle motor.

Once a system has been selected from the configurator and it has been ordered, that’s it! It comes assembled so mounting inside the machine really is simple!! So in answer to the question “How easy is it to construct and assemble a spindle motor?” The answer is really easy!

If you are interested in further information on our spindle motor range, please get in touch!