Avoid machine downtime – incorporate smart plastics in your production line

The cosmetics industry relies heavily on their production lines in order to meet business expectations and perform successfully. Therefore, just like production line’s in any industry, unplanned downtime due to equipment failure cannot be a possibility. The financial cost downtime inflicts on a business is not worth risking. In fact, minimising downtime is immensely cost-effective, as your organisation can be prepared and know ahead of time when maintenance is due and act accordingly in advance. This allows production to remain undisturbed and therefore production doesn’t stop or restrict business revenue. This is where igus® has a smart solution to ensure you are clear from the unwanted downtime disaster.

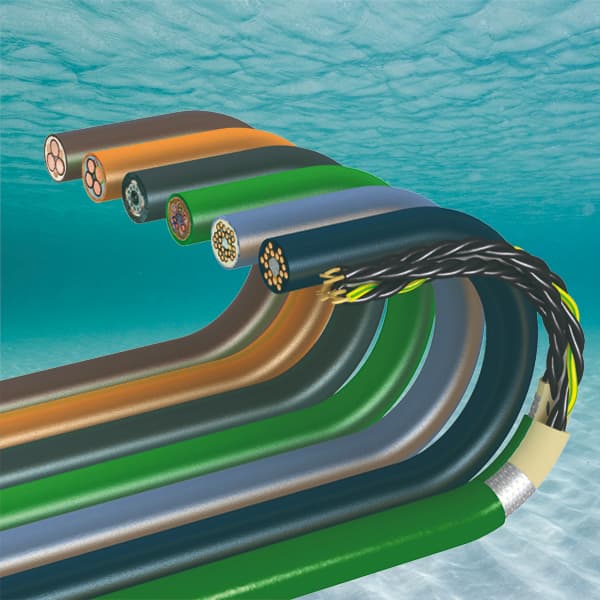

With industry 4.0 at igus®, you won’t have to worry about unanticipated pauses in production that can lead to huge expenses for your organisation. igus® energy chain systems, chainflex® cables and plastic plain bearings can be employed with the required sensors and software to minimise unplanned downtime and create an untroubled manufacturing operation.

The two types of systems igus® provide are: condition monitoring and predictive maintenance. If you haven’t considered converting to our smart plastics technology yet or would like more information around avoiding unplanned downtime with igus®, continue reading.

Condition monitoring

Conditioning monitoring at igus®, also known as i.Sense, is a regular or permanent recording of the machine’s condition using sensors which measure and analyse physical parameters, such as vibration, temperature and position/proximity. The sensor alerts you if one of the values is outside its limit, allowing you time to suggest alternatives or fix the issue before production must pause. This is a perfect preventative solution for industries like cosmetic manufacturing, as your production process will not be impacted by any maintenance procedures.

Other benefits of igus® condition monitoring include:

- Increased machine availability

- Eliminating unplanned downtime and machine failures

- Reduce maintenance costs with early warnings

- Easy to integrate into industry 4.0

- Better fault analysis thanks to real-time machine data acquisition

Predictive maintenance

Predictive maintenance or i.Cee, is the next step of development from condition monitoring. It is a system which calculates the perfect time for servicing as well as determining the best maintenance solutions with igus® products. Therefore, you can transform stock products, such as our energy chains and plain bearings, into intelligent products. igus® i.Cee is available in a variety of designs to offer a high level of individuality and suit every production line in all industries.

Some more benefits of using igus® predictive maintenance are:

- Avoids expensive production losses due to unplanned downtime

- Reduce maintenance and servicing costs

- Maximise the service life of the igus® components you are using

Which smart system should you acquire to prevent unplanned downtime?

Both smart plastic options provide solutions to prevent unplanned downtime of your production line, however, depending on your specific requirements, there are different characteristics provided by i.Sense or i.Cee for different scenarios and solutions.

i.Sense

Employing condition maintenance within your production line is advised if you wish to have a shutdown function for your energy supply system to avoid a crash, or if you are trying to avoid software for monitoring your energy supply. i.Sense also provides a status report if you require a warning of machine abnormalities which can proceed a cease in production.

i.Cee

Predictive maintenance is recommended if you wish to transform stock products into smart products, know the current service life of the igus® components and when they are due for maintenance. i.Cee is also advised when you wish to avoid risks of unscheduled machine downtime.

Cosmetic manufacturing and many similar industries depend heavily on sufficient machines and automated processes day-to-day. Therefore, if you have the option to prepare for maintenance and avoid unplanned downtime, then why wouldn’t you?

For more blogs relating to igus® smart plastics, click here.