Cable designs and why chainflex® cables are superior

A question for you. If you need to supply data or energy on moving machinery, what do you need? igus® has the answer….

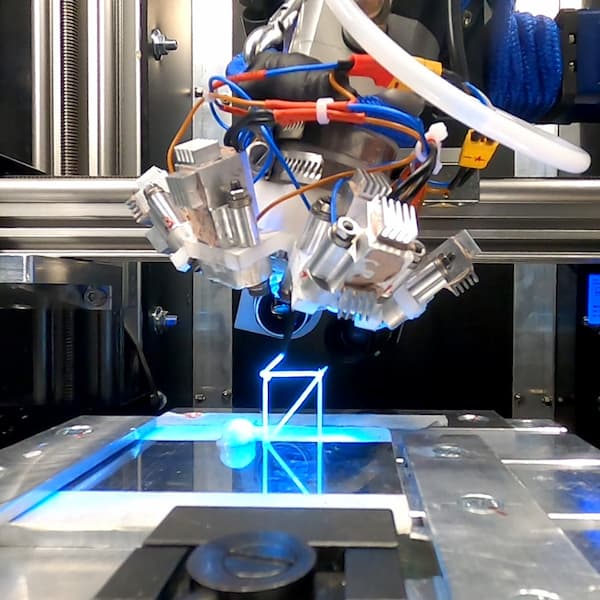

In order for a moving energy supply system to function properly, it requires the perfect operation of all components, including the electrical cables being used in the system. In the early 1980’s, igus® began to develop complete energy chain systems. chainflex® cables and energy chains are offered from a single source and with a system guarantee of up to 4 years, that’s how confident igus® are with their products and their testing.

Since the introduction of chainflex® cables in 1989, millions of tests have been conducted to ensure that the design is optimal. Original design principles remain; however, these are constantly being developed to ensure that the products are always the best that they can be.

Let’s look at some key cable design features to get a better understanding of why igus® chainflex® cables are becoming so successful.

Properties of winding in layers

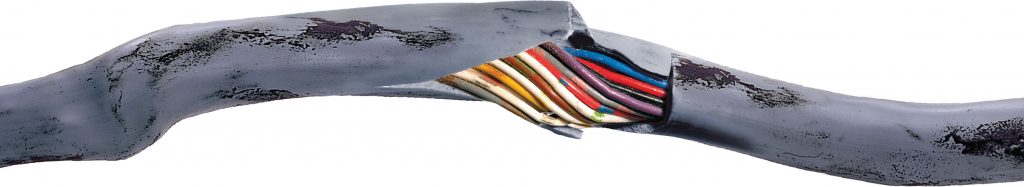

Winding cores in layers is significantly easier to produce and is therefore classed as low-cost cable. But this type of cable can suffer from “corkscrewing”. How do these problems arise? In the case of winding in layers, the cable cores are wound in several layers and are then provided with a jacket in the form of a tube. In the case of shielded cables, the cores are wrapped up with fleece or foils.

So, what causes the “corkscrewing”?

The bending process compresses the cores along the inner radius of the cable and stretches the cores laying along the outer radius. Initially, this might work quite well because the elasticity of the material is sufficient, but it doesn’t take long for the materials to fatigue. This can cause permanent deformation and, due to the stress of movement from the neutral axis,, the cores fall into compression and tension zones.

The “corkscrew” is therefore created, often followed rather quickly by core or jacket ruptures and failures.

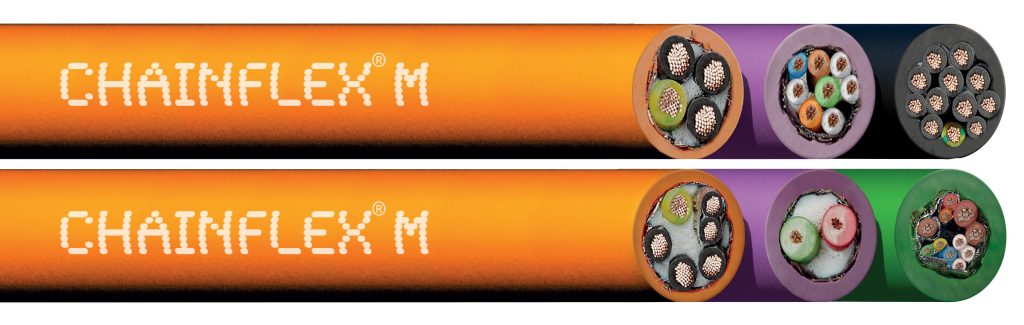

The bundled design

The bundled design eliminates the problems discussed above through its more sophisticated, internal structure. Here, the cores are wound with a special pitch length first and then the resulting cores are bundled. For large cross sections this is done around a strain relief element.

Due to this design, all cores move through the inner radius and the outer radius of the cable several times at identical spacing distances. Tensile and compressive forces balance one another around the high-tensile centre cord giving the structure its stability. In this way, the structure remains stable even under maximum bending stress, so corkscrews are less likely to form

Below 12 cores, layered cores can work, above 12 cores, a bundled design should be used.

Stranded core design

With respect to the selection of core strand wires, maximum flexibility is vital. Although very flexible conductors can be made using very thin individual strands, these conductors are not optimum. Long term testing provided the result that a combination of strand wire diameter, pitch length and pitch direction offers the best overall bending-resistant solution.

Broken cores; what can cause this?

Where you see failure of electrical conductivity it tends to be due to broken copper strands. This can be as a result of subjecting the individual cores to mechanical load under constant bending stress. In most cases, the causes are incorrect strand wires and/or incorrect stranding pitch directions and lengths.

Why choose igus® chainflex®?

The design principle of the chainflex® cables is to avoid problems such as “corkscrews” and conductor breaks in cables in moving applications. In contrast to the frequently offered “chain-friendly” cables with braiding in layers, igus® manufactures chainflex® cables according to the principle of braiding in bundles. igus® have a multitude of materials from which they manufacture shields and jackets for their chainflex® cables. The cables have specifically been designed for use in energy chain applications, so are ideal for movement.

All the above means that we can offer a guaranteed long life. It may seem confusing with all these options so let igus® simplify it for you. You provide the problem and we will provide the cable solution.