Can car parts be 3D printed?

As technology advances, so do the capabilities of sectors such as manufacturing and engineering. 3D printing is a popular talking point and for good reason! 3D printing allows for more complex designs to become reality, designs that traditional manufacturing processes were not capable of creating.

3D printing can be useful to a variety of industries, but one not often discussed is the automotive industry. This blog will look at how both modern and vintage cars can benefit from 3D printing.

The advantages of 3D printing

There are many benefits to 3D printing parts from faster prototypes to better quality products as 3D printing allows for quicker testing cycles and more precisely executed designs. Not only will this save time, but long-term, it should save money too.

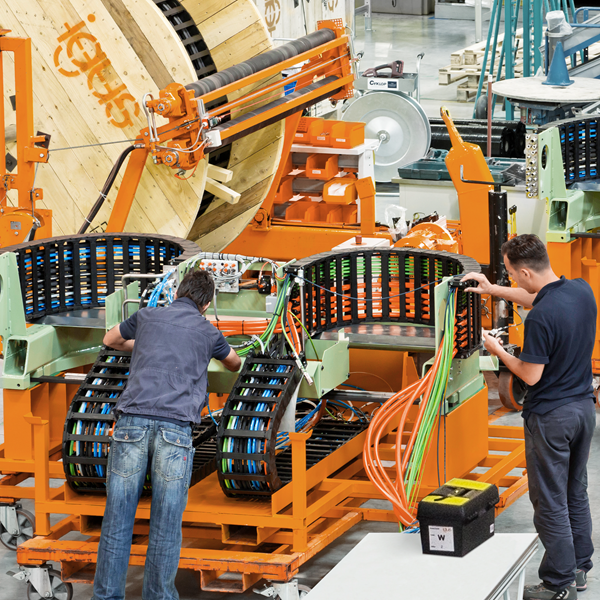

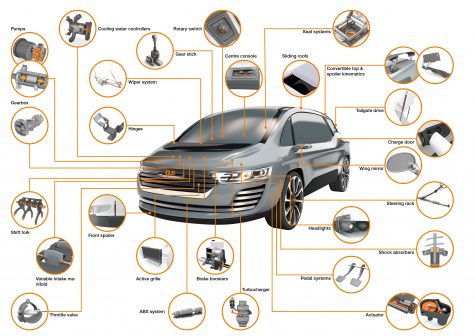

igus® high-performance plastics are corrosion-resistant and lubrication-free, long service life makes them reliable components that offer technical advantages at lower costs. From adjustable seats to plain bearings in coolant pumps, igus® products can help with automotive manufacturing solutions.

Vintage Vehicle Parts

An interesting and niche area of application for 3D printing is in vintage cars. A recent visit with a member of the Federation of British Historic Vehicle Clubs was the perfect opportunity to show what igus® can offer in this area.

For particularly old and rare vehicles, sourcing replacement parts in a good condition is increasingly difficult. 3D printing these sought after parts can provide an exact replica, easily made and cost-effective. At igus®, the iglidur® i6 laser sintering material is used as one of the most wear-resistant materials on offer.

Problem solved

In the Stewart Warner speedometer, the gear on the first intermediate shaft which meshes with the worm on the input shaft was no longer in working order. Due to the work done on the speedometer by the previous owner, it was impossible to determine the correct dimensions and so a replacement worm gear was needed that would be durable, precise and low-cost.

With the igus® 3D printing service, a fully functioning spare part was made from iglidur® I6 and additionally, the use of self-lubricating polymers meant that the component no longer required lubrication. Even after being in use for more than 2,000 miles, no signs of wear were detectable.

Disadvantages of 3D printing

Despite being such an innovative approach to production, the 3D printers themselves can consume a significant amount of energy in order to function, and the initial cost of investment to buy these machines can often be prohibitive. igus® can remove roadblocks such as cost or limited knowledge on how to operate 3D printers by printing parts for you quickly and cost-effectively or at least supplying the right materials based on your requirements for you to print the components yourself.

If you’re looking for high volume this may not be the ideal solution as 3D printing is well suited to mid-level volume production.

However, the advantages far outweigh these setbacks and buying 3D printing machines is widely considered a worthy investment. The range of possibilities that it can provide opens up the world of manufacturing so that so much more can be achieved that was once out of reach.

Get to grips with 3D print in more detail or to become an expert in this field, contact us for specialist advice and learn where igus® could be implemented into your business or projects.

Different types of 3D printing technologies

As the website Future Learn describes, there are several types of 3D printing, but here at igus® we can provide parts using these 3 methods:

igus® elsewhere in automotive

igus® don’t just provide 3D printed parts for vintage cars, we cater to requirements in modern vehicles too. This video shows other areas where igus® products can improve movement, in this case using ball bearings.