High temperature bearings, what are the effects?

One of the most frequent questions asked by customers when it comes to high temperature bearings is, “What temperatures can they handle?” The only question more commonly asked is, “How long does it last?”

Often the topic of temperature resistance refers to the material’s mechanical resistance, how long will it last? It is no secret that plastics become softer when certain temperatures are exceeded and of course, that is bad for many plain bearing applications. But temperatures actually play a much more important role in the behaviour of plastic plain bearings….

Effects of high temperature bearings, specifically plastic bearings.

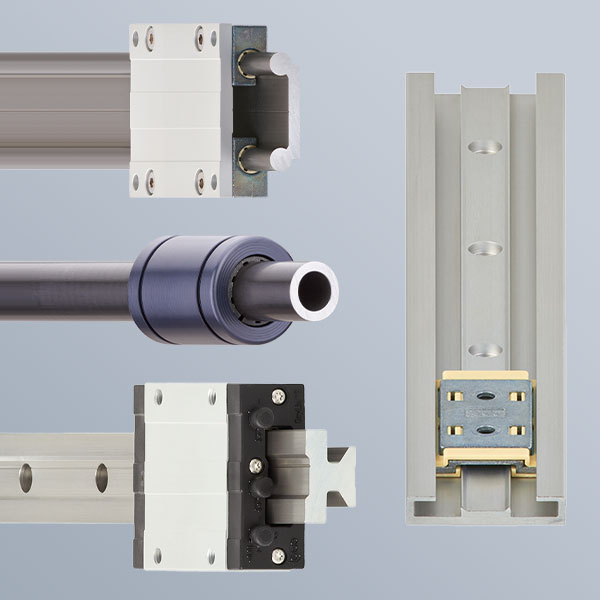

If plastic is heated beyond a certain point, it loses its mechanical strength. However, not all plastics behave the same way. Thermoplastics can be deformed under high temperatures and can regain their strength after cooling. However, this can result in loss of tension also known as ‘relaxation’ of the bearing.

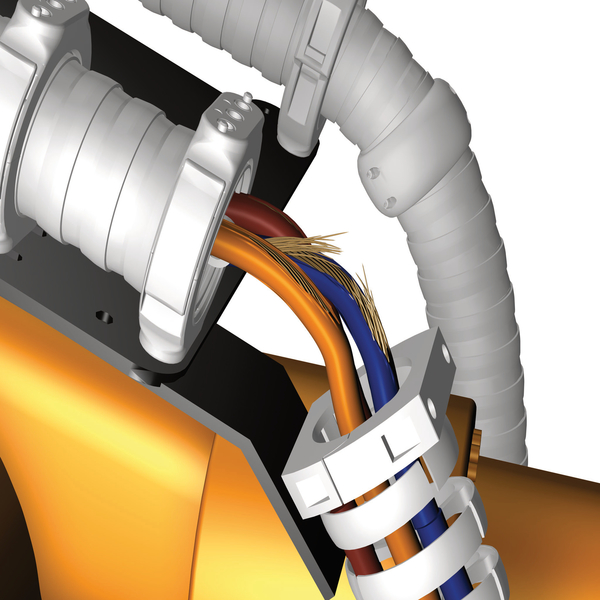

Consequences of heat-related relaxation in plain bearings can be seen in the loss of the press fit in the bearing point. But other deformations are also possible. The direct result of softening can be that the supported load can cause the bearing to flatten. This happens when unintended mechanical stresses occur after deformation, such as when the bearing partially moves out of the housing or tilts.

At what point are temperatures “too high” for plain bearings?

Temperatures are too high whenever the recommended temperature in the material data sheets is exceeded. In theory, yes, however, the data sheet information is usually an approximate figure applied under certain conditions, so the situation is slightly more complicated.

What is a PV value?

Understanding the PV value is crucial when looking at high temperature bearing capabilities. The PV value provides information about the suitability of a bearing for the specific application. It represents the velocity and surface pressure and it also provides information about the heat generated in the bearing per unit of time. If more heat is generated in the application than the bearing point material can dissipate, the bearing point will heat up.

Is the ambient temperature the only important parameter?

Concerns about temperature resistance often focus entirely on ambient bearing temperature. For example: a plain bearing for an oven door. In this case, it is correct to compare the ambient temperature with the temperature resistance.

The PV value is quite low for an oven door, it is realistically opened at relatively low speed and infrequently. But on the opposite scale, take a fast-running conveyor chain INSIDE an oven? Or a pump bearing within a pump delivering hot liquids? Even if the liquid or ambient temperature is low compared to temperature resistance, there is a risk of a bearing failure or underperformance if the load and motion profile result in a PV value that is too high.

How to choose the right material in your high temperature for your application

Most plain bearing application scenarios can be solved with the right plastic. Regardless of the quantity, using igus® online tools or our sales teams, we can work with you to determine the most suitable plastic for your application, support you in the design of the finished component and manufacture the component for you using the most cost-effective manufacturing process.

If you want to read more about questions asked about high temperature bearings, you can find many answered here https://blog.igus.co.uk/common-misconceptions-about-plastic-bearings/ or check out these frequently asked questions https://blog.igs.co.uk