How quickly can you save money with condition monitoring?

To understand how you can save money with condition monitoring, we need to firstly understand what it is.

What is condition monitoring?

Condition monitoring refers to a system which regularly or continuously records or monitors the condition of a machine. Then in the event of a component or sub-system failure, or damage, the overall system can give an alert allowing inspection of even machine shutdown to limit further damage, downtime and cost. This is especially prevalent for rotating components or moving applications. There are obvious operational benefits for maintenance managers such as maximising production in terms of OEE and increasing the service life of the plant landscape. All of which is good, but when it comes to saving money, how quickly can this be achieved?

How quickly can you save money with conditioning monitoring?

The financial benefits of Condition Monitoring Systems are often difficult to assess, the initial investment in a condition monitoring system increases costs, this is obvious as the need to invest before you see a return is always the way these things work. However, it can seem quite daunting so in the next few sections, we will look at the financial impact over the entire utilisation period with a break-even analysis based on practical experience in an automotive production hall.

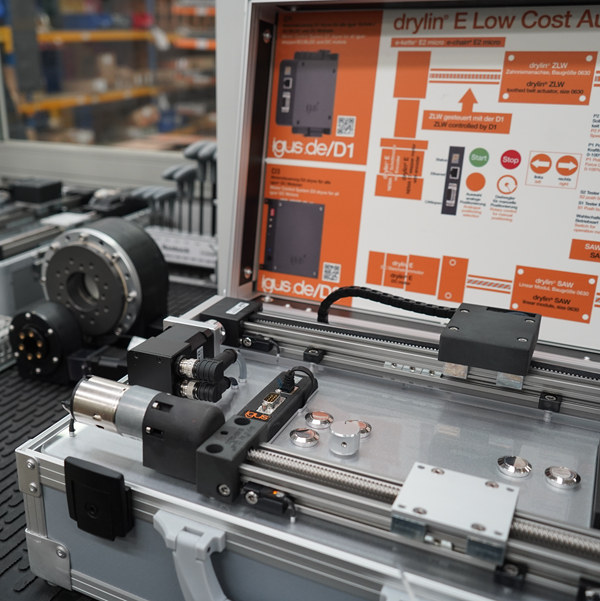

Ready-to-install condition monitoring systems for under £2,000

Let’s start by looking at the procurement and installation costs for a condition monitoring system such as the igus® i.Sense. This is the sensor part of our Smart plastic range. Depending on the sensor chosen, a complete package for fitting to a new, or in some cases existing, energy supply system, this can be ordered for less than £2000. The setup can be done completely on your own with the accompanying operating and installation instructions. Beyond that, no further costs are incurred during the service life.

Typically, in manufacturing plants, there is a requirement for regular maintenance work that has to be carried out continuously. These may include the following examples: changing oil in a crane system, maintaining a manufacturing machine, or monitoring a production facility using measurement technology.1

Since these efforts can be very different per use case, let’s approach it in 3 different scenarios:

- Regular Case – Optimally designed energy supply system with normal capacity utilisation

- Busy Case – Fully utilised production line in 3-shift operation

- Crash Case – Complete failure of the production line.

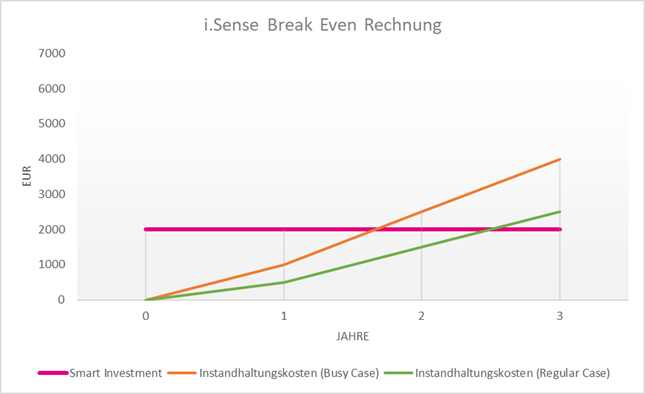

Break-even is reached in the first year of use under normal operation

Expenses are maintenance costs that are spent on maintaining the upkeep of operating resources. This includes all costs that keep operating equipment in a serviceable condition.2 For the energy supply on a gantry in a production line for example, this can include the following typical efforts in the regular case:

- Weekly inspection of the travel for contamination or objects (each 10 min)

- Monthly check of the cable package and re-calibration of the push/pull forces (a 30 min)

If these expenses are compared with the average costs in the manufacturing industry in the UK of approx. £45 per working hour3, the benefit threshold of an i.Sense system is reached within 3 years of use.

In this “regular case”, we assume a properly designed and smoothly operating energy supply system so, if we have a production line running under full load in 3-shift operation, we can expect further expenses:

- Daily visual inspection of the travel (each 3min.)

- Half-yearly inspection of the complete energy supply (each 240min.)

In this “busy case”, the break-even point for a modern condition monitoring system like i.Sense is reached in just under 1.5 years:

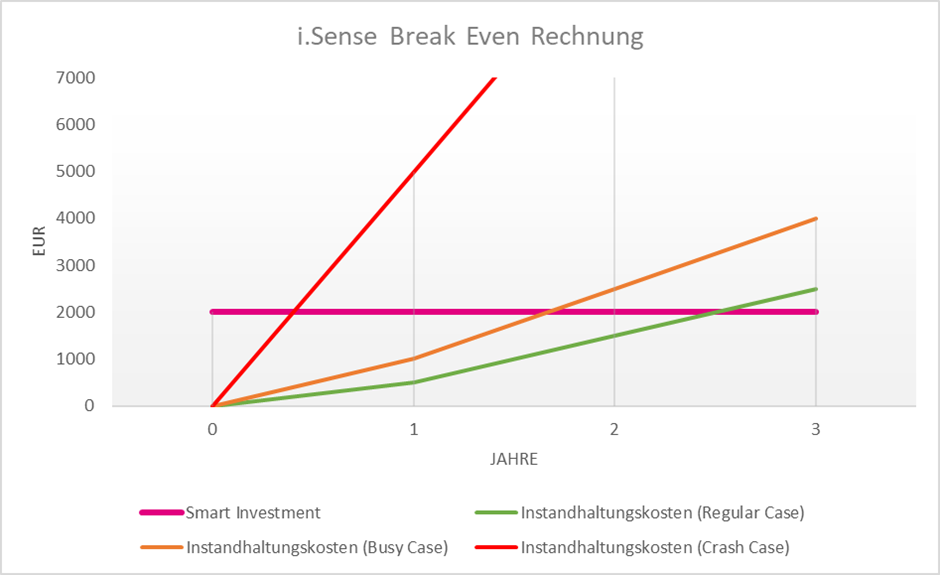

Avoidance of a total failure with i.Sense EC.P can hardly be measured in monetary terms

However, the main advantage monitoring permanent push/pull force with i.Sense EC.P we have not even mentioned, the immediate stopping of the system in the event of an abnormal increase in force. This can be caused by any external impact in the form of tools or other objects left lying in the path of the travel. With the emergency stop of the plant and informing the responsible person for the machine, consequential damages or even total failures can be prevented.

The occurrence of such a total failure typically cannot be predicted, but in the worst case it will be expensive. In the automotive industry, downtime can cost thousands of pounds per minute; one of our customers in the crane industry was even able to avert damage of several tens of thousands of pounds. This crash case must therefore be avoided at all costs … which is why the option of smart condition monitoring system from igus® is the perfect choice.

So, in answer to the question, how quickly can you save money using condition monitoring? The answer is relatively quickly!

For more blogs on smart plastics click here

Sources: