How to make a lead screw

How do you actually make a lead screw? What does the process involve and what is the difference between the thread rolling and thread whirling manufacturing processes?

There are two key manufacturing methods: thread rolling and thread whirling and this resource will look into both so you can better understand which one would suit you and your applications best.

The process of thread rolling a lead screw

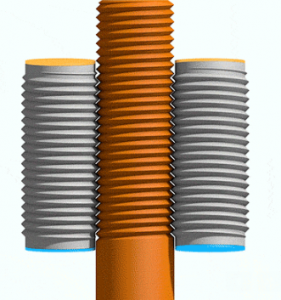

Unlike thread whirling, rolling works without cutting. The actual manufacture of the lead screw is simple. A workpiece is placed centrally between two tools and they rotate simultaneously. The thread is literally rolled into the surface of the raw material by cold forming (when metal is shaped below its recrystallisation temperature). The thread profile has been transferred to the workpiece by the compressive stress and rotation and so the thread is created.

For high volumes, this method of production is faster and more cost-effective than thread whirling. This is because the material requirement is lower. In addition, cold forming achieves a hardening of the surface and higher strength. The pitch angle, the high surface quality of the rolled thread and the low coefficient of friction of the plastics result in high efficiency and a long service life of the lead screw, making it the preferred option for many.

The process of thread whirling

The second manufacturing option, thread whirling, is another way to make a lead screw Whereas thread rolling requires two tools, the thread whirling process requires just the one. Ring-shaped and clamped around the appropriate workpiece, the screw rotates very slowly, while the whirling tool rotates outside at a much higher speed. The thread is produced with inward facing cutting elements in the tool that effectively carve the required shape.

This process is ideal for producing very precise threads that require a particularly high surface quality. This means that the the edges are sharper in comparison to thread rolling and its flexibility makes it suitable for a wide range of thread geometries. The process is often used for materials that are poorly suited to thread rolling.

Configure what you need with igus®

Our lead screws can be easily designed online. In just a few steps you can download the CAD data from our configurators, including production drawings free of charge. CAD software or knowledge in handling CAD programmes is not required and if you need any help, you can always contact our expert for more information.

In addition to the configuration tool, igus® also offers a wide range of products on the online shop that will suit your requirements.

Both processes have their areas for application but igus® uses thread rolling as standard because of the cost savings, better surface finish and longer service life. Thread whirling is more suitable for small quantities and for very precise threads with narrow tolerances. It always depends individually on the required specifications and application.

Our experts would be happy to advise you on the selection of the right lead screw for your application and to become even more knowledgeable on the subject, read more here!