Identifying the right leadscrew nut for your application

In the manufacturing world, it’s easy to overlook “the basics”. But the reality is, the fundamentals of modern machinery are heavily relied upon to allow us to do the job required. Now, more than ever, the world is relying on production & automation which in turn relies on suppliers like igus® to provide long lasting solutions for these industries.

This is where our “tech up, cost down” ethos highlights that as a company and a supplier, we are here to help.

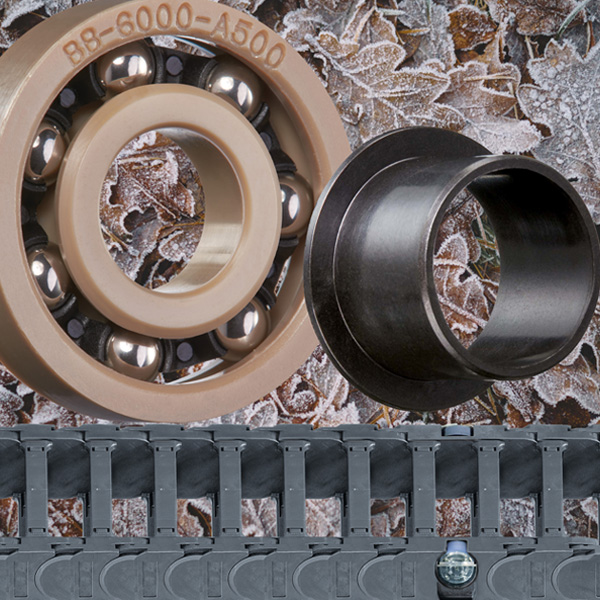

igus® has been producing high tech polymer solutions for over 50 years now, and sometimes due to their less fashionable, yet functional form, leadscrew nuts often get overlooked as a credible solution. The market for leadscrew nuts is a congested one and is highly competitive, however, unlike igus® leadscrew nuts, what most suppliers don’t have is the ability to accurately predict the lifetime and wear characteristics of these unassuming yet vital components.

So why igus®?

Here are just a few benefits of using igus® iglidur® materials:

- Temperature resistance

- Corrosion-resistant

- Low humidity absorption

- Chemical resistance

- Lubrication and maintenance-free

- High wear resistance

- Silent operation

- Low Friction

- FDA-compliant plastics and certification to EU regulation 10/2011

With the choice of 7 materials for standard products and having many more material options available as ready- to- machine bar stock and stock plate, being able to custom design and produce bespoke products enables the best solution to be found for the customer.

Choosing the correct pitch, direction and size for the leadscrew nut

With a range of materials, thread pattern and direction it can be difficult to know what to choose. igus® has developed configuration tools which can help identify the customers exact requirements but if you need more, there are product specialists at the end of the phone, on email who can visit, either virtually or physically.

Here is a snapshot of the 7 standard products:

1. We have iglidur® J, “the endurance runner” which is ideal for machines needing to run marathons! This material perfectly combines low coefficient of friction and long life when running dry.

2. iglidur® R, “the red one” for the those needing to save the pennies. A material focused on high performance and very low cost.

3. iglidur® J350. For when you need to work at a higher temperature.High temperatures can mean hard work but igus® has done the hard work by developing a high- temperature material to create a high- temperature nut.

4. iglidur® A180 is the FDA food compliant material. The FDA nuts remove the risk of small parts contaminating the production line. Due to being dry running, this eliminates any lubrication infecting the food line.

5. iglidur® J200, is the perfect accompaniment for hard anodised aluminium shafts! Many materials can give low coefficient of friction under high loads, but this material can give excellent coefficient of friction even at low loads.

6. iglidur® W300 has an extremely high wear resistance and an especially long service life. Excellent wear resistance, even in harsh environments.

7. And finally, iglidur® E7 “the durable runner”. This is the ideal material when using steel shafts at higher speeds. A new material with outstanding results.

Construction and assembly of lead screw motors

As the name suggests, a lead screw motor consists of a lead screw and a motor … and a driven nut.

The motor is designed as a stepper motor with hollow shaft. These motors are specially designed to absorb axial forces. For example, our NEMA23 lead motor can axially absorb 500 N where conventional stepper motors would be damaged. In the hollow shaft there is a holder for our lead screws so that they can be screwed and glued. This connection is so powerful that it can only be released with the right tools and a specially developed process.

The motor can also be equipped with an encoder and/or industrial M8 connector. The lead screw has been specially machined for this motor so that the thread starts directly from the motor flange so there is therefore no loss of stroke.

Finding the right lead screw length

The definition of lead screw length is somewhat tricky, but easy to understand:

- Lead screw length = total length incl. assembly pin and crank

- Unsupported lead screw length = lead screw length from motor flange without assembly pin and crank

- Stroke = unsupported lead screw length minus the length of the nut

All igus lead screws can be coupled with the motors, but it’s about finding the right solution for your application. Since the lead screws require special machining, we have a defined number of lead screw geometries in stock which are cut to length as required, and you can find an overview of the lead screws we provide on our website.