Predictive maintenance products Can Help You Save Time & Money.

Predictive maintenance seems to be the topic of every article and video I see it is understandable as to why. This technology really can save companies and customers time and money by pre-warning the user when wear is starting to occur. It is very clever when you think about it. This technology is “talking” to you.

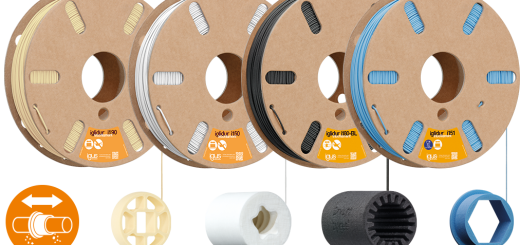

I have mentioned this in previous blogs, but this is not new technology. However, igus® have recently adapted the way in which the “smart plastics” are described to customers. We now offer 2 different approaches to this technology. We offer condition monitoring (our name “i. Sense”) and predictive maintenance (our name “i.Cee”).

The idea of this blog is to describe the differences between these two approaches and provide a greater understanding to which would be best suited to your application. Maybe both options would be useful for you, you can decide.

How it all began

Initially, igus® started with this predictive maintenance in energy chains many years ago. This technology, as with all technology, has grown, adapted and advanced and became known as “smart plastics” within the igus® world.

Read more blogs about our energy chains here.

We have had numerous success stories with this technology being used in energy chains on cranes, within large automotive plants and on main production lines within factories. Their success lies in the ability to communicate the current state of the energy chain to the control box and make someone aware of damage and therefore potential failures. The sensors within this system were able to detect if the energy chain was suffering from an overload or breakage at the early stages and prevent further more costly damage. This is classed as condition monitoring. Let’s look at features of this;

Condition monitoring in energy chains:

- Push/pull force monitoring (“EC.P”); this measures the forces and can detect an unexpected increase in force and therefore an impending breakage. The sensor recognises the change in force or breakages and warns/shutting the system down.

- Breakage detection; There are various parameters which can change within applications that are unforeseen, so this detects breakages and notifies the control box immediately, preventing additional damage.

- Pull force monitoring; This is more relevant for the cables. It can identify stress on the cables and can trigger a shutdown if required.

Condition monitoring is easy to integrate within your machine and operates without any additional external processing modules. This is a key difference between the condition monitoring and predictive maintenance.

Predictive Maintenance:

The concept of this system is to determine the products life span. A great analogy would be; in a car you may get a warning message to say your car requires a service in 1000 miles. This is predicting when your car requires the maintenance. If you thrash the car this will decrease rapidly as the parameters have changed from the cars algorithms where it has analysed the driving data.