Why lubrication-free might be the better option for your ball bearings.

Here’s a simple question. Do you need to grease ball bearings? The answer is equally as simple. Metal ball bearings, yes, igus® xiros® ball bearings, no.

When installing metallic ball bearings, grease or lubricating oil is essential and as a result, can remain on hands and can be very messy. With xiros® polymer ball bearings, you can enjoy lubrication-free ball bearings. No grease! No oil! No mess! Most applications utilising ball bearings are predominantly low load and low speed. Ball bearings made of polymers can be used in multi functional applications, such as cases where they come into contact with liquid media, water or chemicals, which is detrimental to metal bearings.Even in applications with elevated temperatures up to 150 °C, xiros® ball bearings can be a better alternative to metal and even ceramic ball bearings.

But why? Let’s find out….

Ceramic verses polymer

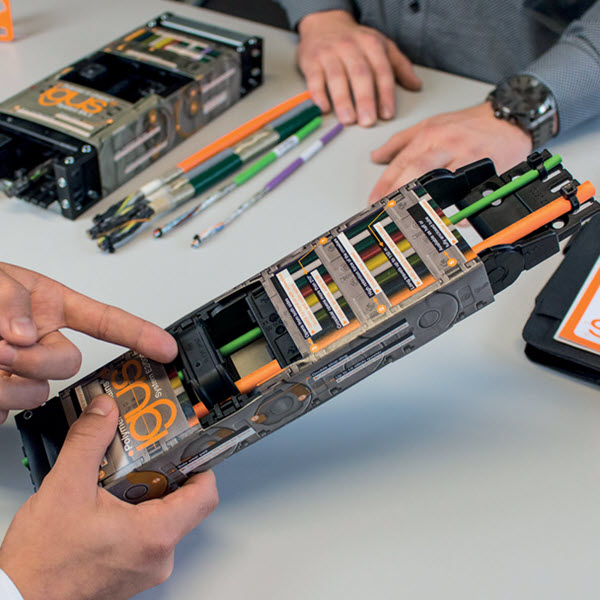

xiros® polymer bearings offer considerable advantages in terms of smooth operation compared to metal. The main reason is that they don’t have to overcome the resistance of the lubricant as they start with a significantly lower breakaway torque. In addition, they are very lightweight and are also available with glass balls, thus ensuring completely metal-free and non-magnetic if required.

xiros® bearings have a range of cage, race and ball materials making these small bearings versatile and suitable for a multitude of areas in day- to- day life. They are also very cost effective when compared to their counterparts in alternative materials.

Another lubricant-free alternative are ball bearings made from technical ceramics. Ceramic materials are generally very wear-resistant, corrosion-resistant, temperature-resistant, light, stiff and electrically insulating.

Despite the significantly higher costs compared to metallic materials, technical ceramics such as silicon nitride, silicon carbide and aluminium oxide have long been established as storage materials. In many cases, for cost reasons, they have so far only been used in areas of application in which the advantages of the ceramics really come into play and where buyers are not deterred by the higher procurement costs.

In contrast to the alternatives above and as mentioned earlier, metallic ball bearings must be lubricated. Without lubrication, these bearings would otherwise rust very quickly and deform in use. This is due to the high frictional forces and the lack of cooling, which worst case would lead to the bearing seizing. Lubrication is essential, especially with sealed ball bearings, otherwise the plastic or rubber seals will become porous. The grease may leak out and the bearing will run dry. The exception is the stainless-steel ball bearings, which do not corrode but these are much more expensive to procure than plastic ball bearings.

Why would you use a ball bearing?

The world wouldn’t turn properly without ball bearings!

Sometimes we don’t see the intricacy of how things are constructed, how life grows and develops. Everything is in motion, it never stops moving. If we took the time to appreciate the technology behind it all, we would notice how underappreciated the ball bearing is. If we all slowed down and explored our surroundings, we would notice, when travelling to work by bike, train, bus or car that ball bearings are located in all means of transportation. But you don’t need to venture far to experience ball bearings. Look at kitchen equipment, training equipment, shower screens or in recreational activities like at a bowling alley – ball bearings everywhere!

Ever since the development of the steam engine and the beginning of industrialisation, ball bearings have become an integral part of our everyday lives. The only difference is that nowadays, the options we have are so much greater than ever before.

The choice is ours, will it be metal and grease or lubrication-free igus® xiros®?