Adam Sanjurgo talks dryspin®

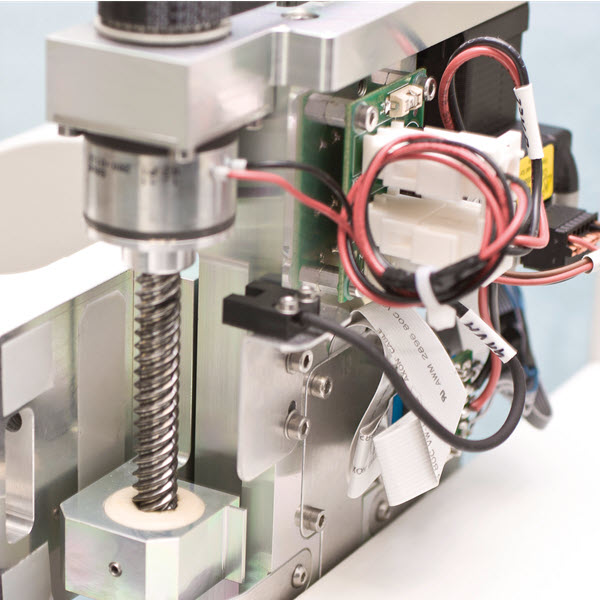

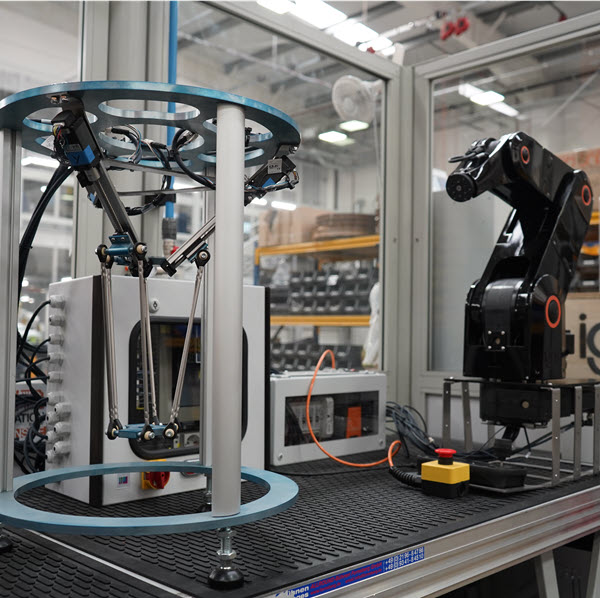

dryspin® is the range of high helix threads designed and manufactured by igus®, these are also known as steep threads or multi-start lead screws. dryspin® has been specifically engineered for optimum lifetime in fast screw applications. This product range still offers the key advantages for which igus® is well known, such as maintenance-free and lubrication-free use, predictable lifetime, ex-stock, corrosion resistance, FDA compliance with resistance to dirt, dust and other media such as chemicals.