An insight into Low Cost Automation

Q & A with Adam Sanjurgo: Low Cost Automation Product Manager

Question:

Can you tell me a about Low Cost Automation?

Answer:

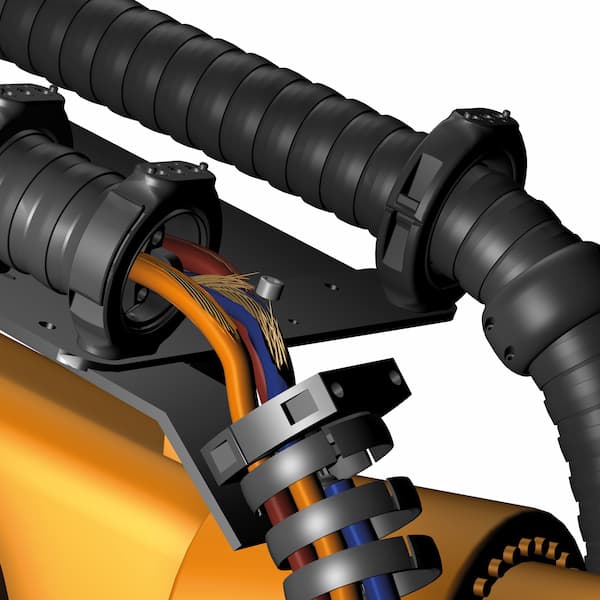

Of course, Low Cost Automation is a group of products within the igus® dry-tech® product range. These products range from something as simple as a lead screw and nut, through to a fully working robot arm. The products offer all the same advantages that our other products offer, they are lubrication-free, maintenance-free, resistant to even the harshest environments, cost-effective, predictable and ex-stock, to name but a few.

The idea behind Low Cost Automation is that we can empower any business in any manufacturing industry to automate processes where maybe cost, resource or simply time was a prohibitive factor in the past. We have a team that is here to support either on-site with the customer, or any customer is welcome to visit igus® to see our range of robots in action, in a dedicated Low Cost Automation area that we also use to simulate customers applications for proof of concept. The idea is simple: if it moves igus® improves.

Question:

What sort of robots does LCA offer?

Answer:

Good question, we have three main robot types that we offer within our range of Low Cost Automation robots. These all have their place and will be selected depending on the task that is required of the robot.

The robots can be described as, fast, flexible and modular. For applications that require a high duty cycle and quick movements, we have our delta robot, this is our fast robot.

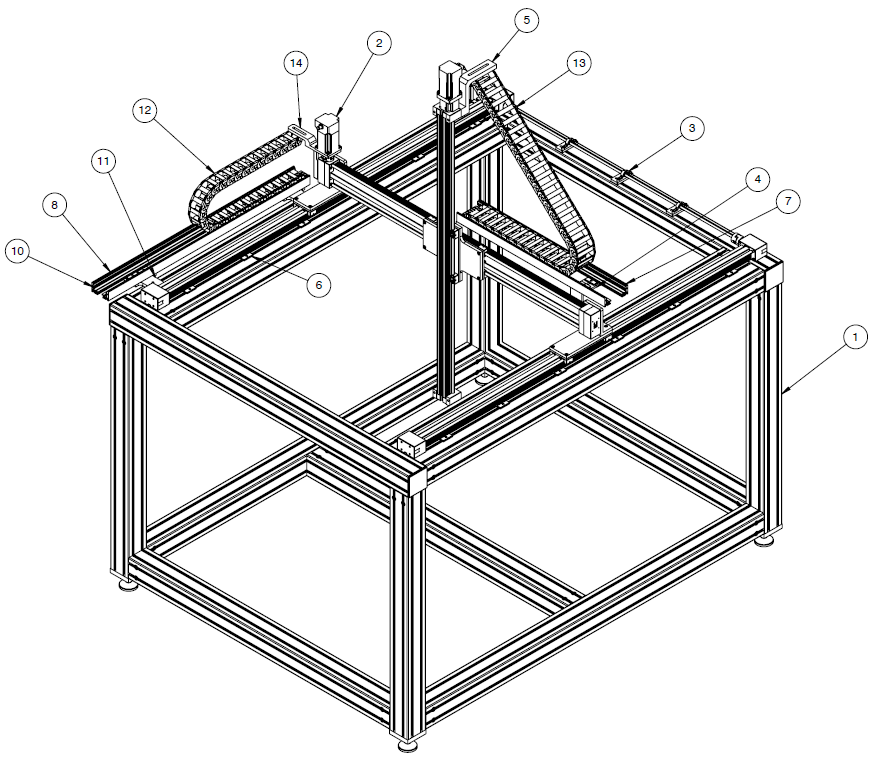

For applications that need to be larger or have more complexity, for example, a high payload, we use our gantry systems (XX, XY, XYZ configurations), this is our modular robot.

Finally, we have our robolink® robot arm, with 4 or 5 DOF available, this robot is our flexible one, as this can be tasked with multiple different applications, and can be utilised for many processes.

Question:

How are the LCA robots supplied?

Answer:

At igus®, we try to be as flexible as possible when it comes to our customers’ needs. This is also the case when it comes to supply of the previously mentioned robots.

For example, with our delta robot, we offer the same robot in seven different combinations, these can be defined as:

- In kit form

- Assembled in a transport frame

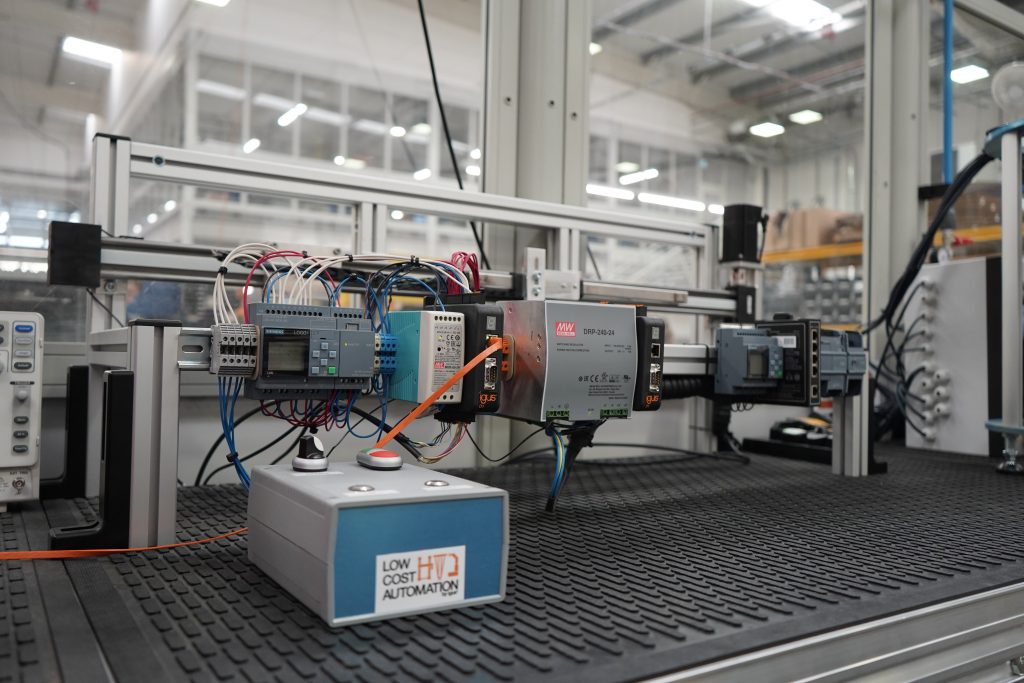

- In kit form, with our dryve D1 stepper motor controllers

- Assembled in a transport frame, with our dryve D1 stepper motor controllers

- In kit form, without motors or controllers

- Assembled in a transport frame, without motor or controllers

- Assembled in a transport frame, with fully functional control cabinet and sample programme

This may seem overly complicated; however, we find it incredibly important to provide a modular system that the customer can tailor to their exact needs. For example, the customer may have prior knowledge with another brand of motor and controller, in this instance the system without motors and controllers is ideal. Or the customer wants the robot to be as finished as possible, so little work is required from their side, in this instance, our seventh option would be the preferred choice.

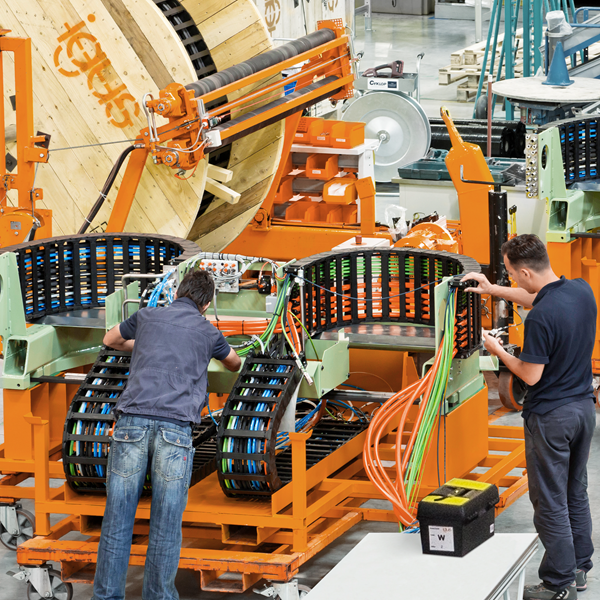

I was specific to our delta robot there, but what about the other robots, for example, our gantry systems. Well again, these can be supplied in a kit form, with or without motors, or we are able to supply the gantry system fully assembled, mounted to a frame, with cable management.

Flexibility to the customer’s desires is key here.

Question:

What are the main benefits of LCA products?

Answer:

As with all igus® products, we have a vast range of benefits compared to conventional solutions. Thanks to using tribologically optimised polymers, we can offer many industries and applications some serious benefits, such as maintenance- and lubrication-free systems, cost-effective solutions, high resistance to dirt, dust and other media, corrosion resistance, FDA-compliant materials, predictable lifetime and deliveries from stock in the UK – to name just a few of the benefits of igus® products.

Question:

What applications do LCA robots work in?

Answer:

Since our products boast huge diversity, we work in almost every industry and on multiple applications. Ranging from food and beverage, packaging and material handling, to automotive, nuclear and offshore industries, we are proud to have so many sectors using igus® Low Cost Automation products. The robot’s themselves are typically used for pick and place automation, either performing a process or aiding a stage within a larger process. Quite simply: if you have a process that you wish to automate, on a new design machine or an existing machine, igus® can help.

Question:

Do LCA products come as standard or can a customer order them bespoke for their applications?

Answer:

Both. We try to be as flexible as possible. Offering standard robots from stock from our factory in Northampton is essential for customers looking for quick turnaround or for prototyping needs. We do however understand that not all projects can be flexible to accept our standard, so we can absolutely work with the customer to offer a bespoke solution perfect for their needs.

Question:

Does igus® offer automation integration?

Answer:

This is a really good question, as integration is a hot topic for most companies looking for a complete solution. Right now, igus® does not offer integration, quite simply because we are a component manufacturer. That said, we do see the importance of supporting the customer through the complete process. For that reason, we have a number of partners who are systems integrators, that have experience with igus Low Cost Automation and robotics, and can fulfil the customers end goal using igus products.

The process is fairly straight forward, igus® will work with the customer directly to ensure the igus® solution is suitable for the task in hand. If integration is required on the project – this can be for a number of reasons, such as time or resource – we would then bring the system integrator involved in the project, to work with the end customer to establish the overall picture of what is required of the finished machine. It sounds complex, but actually, it could not be simpler. igus® and the system integrator then work together throughout the project to bring the finished solution to the customer.

If you have any questions on integration, please do not hesitate to contact me directly.

Question:

Why should I choose igus® robotics for my application?

Answer:

Quite simply, if it moves, igus® improves. Our range of Low Cost Automation robots are enabling automation where usually the cost would be prohibitive. Please talk to us about your requirement, and we will give it our full attention.

Visit the website for more information about our Low Cost Automation range and for more blogs on similar topics visit https://blog.igus.co.uk/category/low-cost-automation/gantry-linear-robots/

Alternatively, contact the Product Manager Adam Sanjurgo: asanjurgo@igus.co.uk with any enquiries.