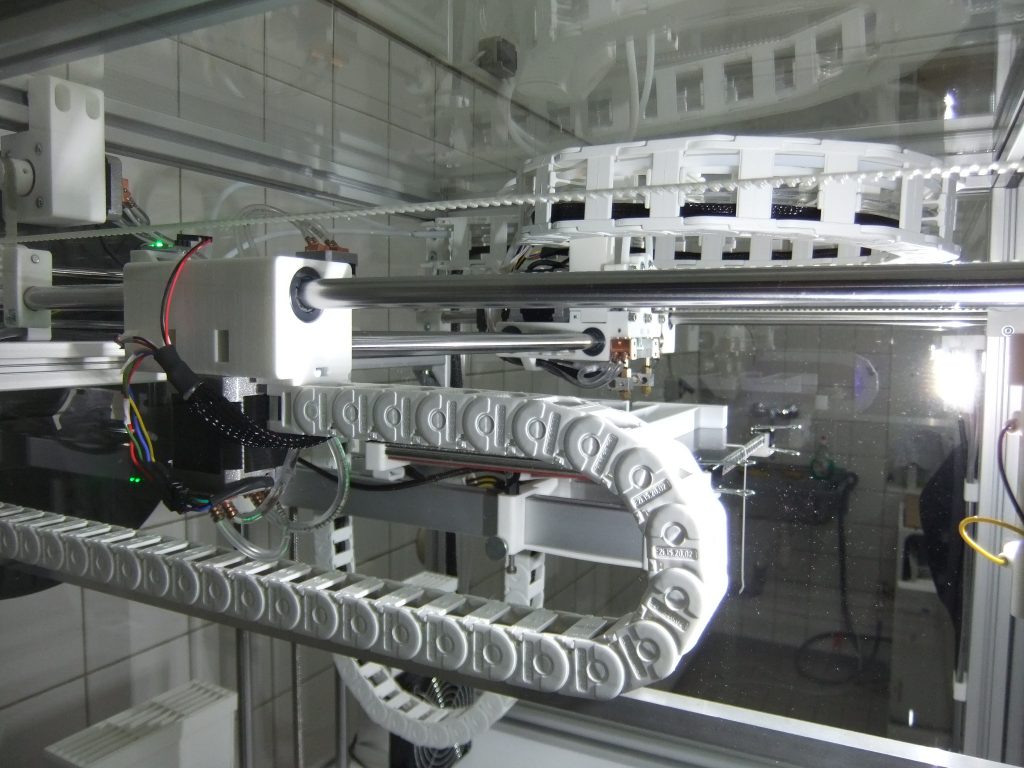

Putting our 3D printed parts to the test

Testing our 3D printed parts

At igus®, we recognise the importance of wear and friction in the industry. It then comes as no surprise that our core beliefs are based on wear-resistant polymers that naturally minimise wear and increase the service life of parts. Thanks to their tribological properties, our iglidur® parts are ideal for myriad applications and industries. From the Greek tribos meaning rubbing, our tribological parts efficiently glide over adjacent components without needing lubrication. Indeed, our parts are designed to be wear-resistant and produce a low coefficient of friction while working in moving applications.

What and how?

In our 3800m² test laboratory, all igus® products are put through their paces to ensure that safety, predictability and function are all the best they can be for each application.

We test wear rates under varying parameters

Linear short-stroke test:

Long and short linear strokes are carried out to define the wear rate (μm/km) of iglidur® 3D printed polymers that are near identical to injection moulded parts. For the linear short-stroke test, we apply a surface pressure of 1MPa at a speed of 0.3m/s along a 5mm stroke. With CF53 and 304 SS shafts, this test lasts for 1 week.

The result suggests that regardless of using moulding or printing methods, our iglidur® plain bearings produce similarly low wear rates and certainly much lower coefficient of friction and abrasive wear rates than the corresponding ABS materials thanks to their tribological properties.

Linear long-stroke test:

Meanwhile, for the linear long-stroke test, we apply a surface pressure of 0.11MPa at surface speeds of 0.34m/s along a 370mm stroke. These tests feature aluminium HC shafts and last for 3 weeks. To test the wear rate (μm/km), we compare the coefficient of wear between standard ABS material and 3 different iglidur® materials – FDM printed, SLS printed and injection moulded.

The results show that the iglidur® materials have high resistance to friction and abrasion and in this way outperform the equivalent ABS materials thanks to the tribological properties.

Pivoting test:

We also perform wear tests on our parts that feature pivoting to further assess the abrasion resistance of our polymers. During these trials, surface pressure reaches 20MPa with a surface speed of 0.01m/s and a pivoting angle of 60°. The shafts used are made of 304 SS and the tests last for 4 weeks.

The results demonstrate the beneficial properties of the iglidur® filaments, which show the long-lasting strength and abrasion resistance of these materials.

Pivoting heavy load test:

We carry out further pivoting tests, but this time apply higher loads to these 3D printed iglidur® parts. Here, pressures of between 10.2MPa and 45MPa are applied, with speeds of 0.01m/s at the same 60° pivot angle. These tests last 1 week and produce more favourable results.

These tests show that our 3D printed parts perform just as brilliantly as the injection moulded parts of the same iglidur® materials. Moreover, we can see that the 3D printed parts can tolerate loads of 1,800kg, thus making them suitable for heavy-duty applications.

Drive nut test:

This wear test uses varying torque, stroke and speed. Respectively, they are applied at: 129Nm, 370mm, 290rpm and last for 2 weeks. Here, we compare the effect of these parameters on ABS polymer parts against FDM printed parts, SLS printed parts and injection moulded parts – which were made from iglidur® materials. The results suggest that iglidur® outperformed conventional materials by a factor of 6 to factor 18 thanks to their lubrication-free and long-lasting properties.

Rotating friction test:

Here, we apply a surface pressure of 1MPa at 0.1m/s with a CF53 shaft material. We observed the coefficient of friction versus the test duration.

The findings suggest that iglidur® i3 performs better in terms of wear resistance thanks to the solid lubricants in the polymer structure.

Worm gear test:

This wear test features a torque of up to 4.9Nm with 12rpm and compares the effects of it working on hard anodised aluminium for 2 months.

The test showed that iglidur® i6 was extremely good at resisting wear when compared to typical materials like polyoxymethylene.