Success with replacing non-igus® with igus®

Flexibility and versatility are key elements that we pride ourselves with at igus®. Not content with just having the standard catalogue parts, we knew we needed to have more adaptability to ensure we were meeting every customers requirement. We have that flexibility with stockbar and stock plate.

So, what’s so special about igus® materials?

igus® materials are perfect for problem solving due to their higher mechanical strengths and homogeneous construction, especially in comparison to the majority of the run of the mill materials. With our life-time calculators we can predict the life span of the part and here are some examples of results where we have changed a non igus® material to an igus® one.

The building and construction industry:

A customer making breeze blocks for the building industry had some lubricated roller discs that were failing due to a temperature parameter. The original material was a steel assembly, consisting of the steel housing enveloping large ball bearings. These discs are used outside of ovens on a small vertical shaft which is attached to the floor. The bearings are used so when the carriage with the breeze blocks on stops in position, the four locking levers slide around the disc, holding them in place while the blocks are slid into the oven. It is at this point that the discs are exposed to the 90 degree heat, when the oven door is open.

We replaced these metal versions with custom machined ones in iglidur® J. The iglidur® material allows for the parts to be free moving, withstand the heat element and are still hard wearing. These are currently still on test and outperforming the original metal ones.

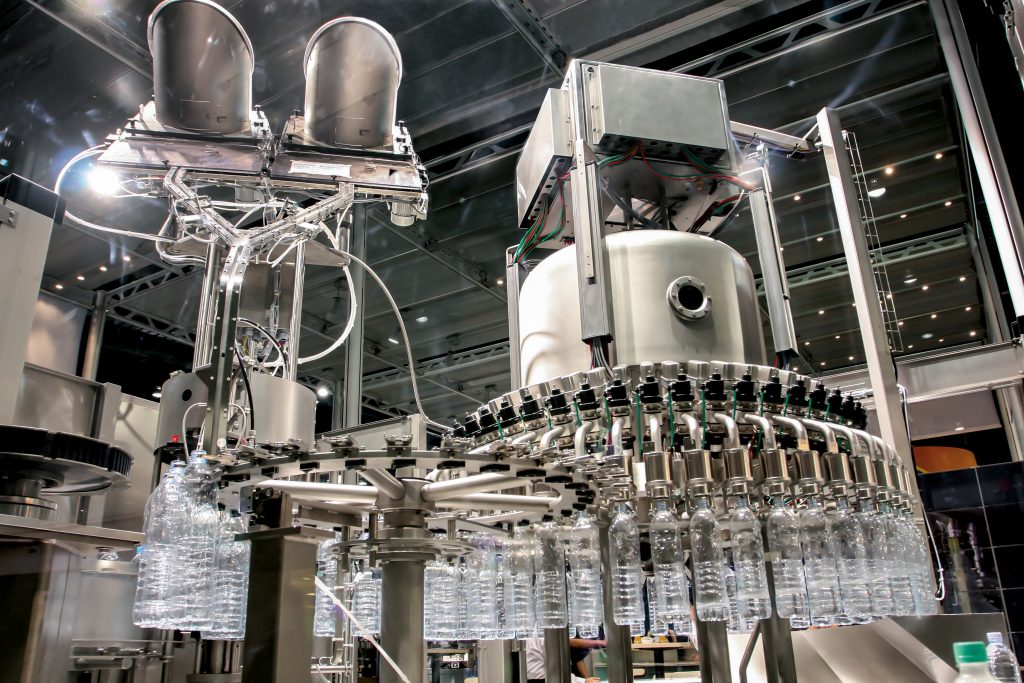

Bottling industry

Example 1.

We were presented with a cam follower within a bottling line that was originally made out of Nylon. It was failing due to excessive wear over a very short period, causing damage to the shafts. The friction was also causing the customer some issues as this was relatively high. The material needed to be high wear resistant, resistant to washdown, FDA approved and low friction. With all of that in mind, we decided to custom machine a test part out of stockbar in iglidur® A350. This proved a success from the offset, with the filling rate being increased and less downtime on the line. The customer has now fully replaced all cam followers with this material.

Example 2.

We were asked by another company to replace a part on a drinks line. This part was originally a stainless-steel part, which was conjoined to 2 plastic seals. We redesigned the parts and replaced them with one complete part in iglidur® A350. Designing it into one part reduced the product getting stuck between the part and the shaft. This has been on the production line for over 2 years now which has massively outlasted the originals, saving the customer time and money!

In both of these instances, we were initially more expensive than the originals, however due to less downtime and the products lifetime being longer, it was a more cost-effective option in the long run.

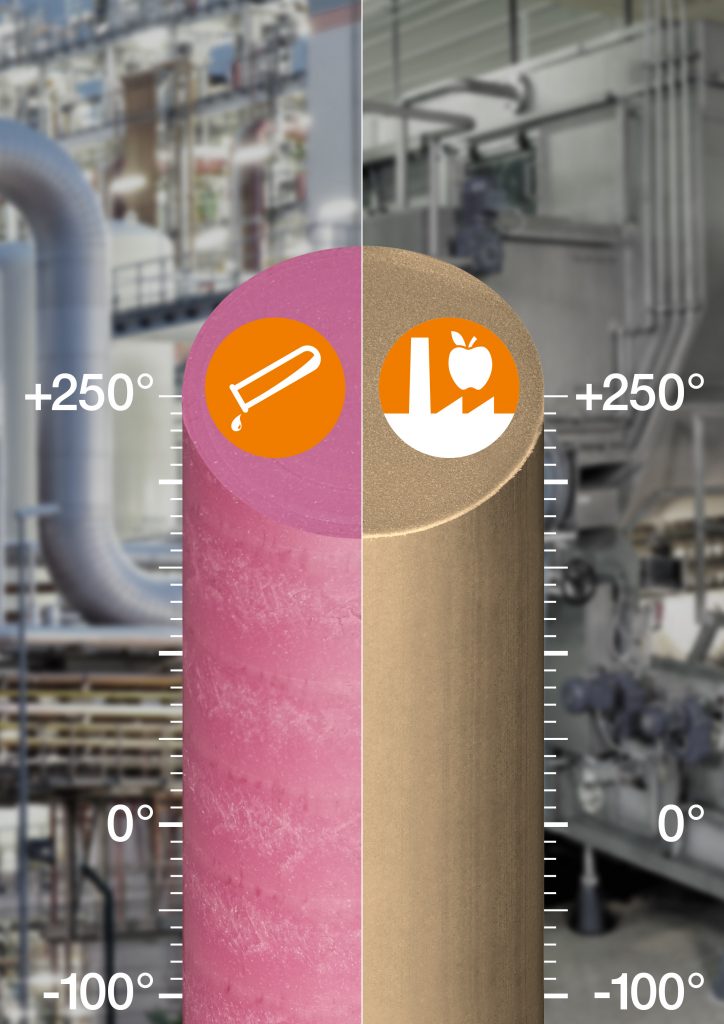

Medical.

We make a cooling bar for a contact lenses manufacturer and the material we use is iglidur® C500. The customer was using PEEK bar originally, but the part was wearing out very fast due to chemicals and solutions. Initially, when the problem was shown to us, we tried iglidur® A500 but this wasn’t as effective as we had hoped. So we looked at other materials that would be suitable, introducing the pink stuff! Iglidur® C500. This is working.

The customer has its own machining capabilities in house. This means that they are now not replacing the parts as often as they were, reducing the down time and the time spent on the machines. We reduced the replacing cycle from 12 times a year to just 3!

Inspection equipment.

We were asked to look at a knuckle joint within a bore hole inspection system. Originally the parts were bronze and they were wearing too rapidly. These parts were acting as a wearing part inside the knuckle joint. We instantly looked at iglidur® X because of the high temperature required, the high chemical resistance needed and the wear resistance. After producing some samples, they were run in the test environment, surpassed all expectations and have since been ordered.

The igus® moto is “yes we can”