The fairy tale of the finest stranded wire

“The strand wire must be fine, otherwise it won’t flex well,” or “I need a class 6 conductor in a robot cable”; these are statements that we often hear from customers. This is often usually preceded by a broken cable, which led to machine downtime. As a result, there was often a loss of production or expensive repair costs.

What is a strand?

A core is the part of a cable that is responsible for the current flow. This is covered by the insulation so that the current does not leak into the neighbouring cores. If the core consists of more than one piece of wire, it is referred to as a strand. This stranded structure when covered with an insulation layer is a core.

There are different classes of strands

The different applications for cables inevitably have different demands for durability in motion. Naturally, an underground cable is never moved whereas a cable on a pick-and=place machine moves millions of times. As a result, the conductor must be of different flexibility in order to cope with this as well as other factors such as haptics, connection technology, processing and also cost.

IEC / DIN EN 60228 (VDE 0295) divides conductor into four classes in order to roughly classify how “flexible” the conductor should be. The criteria for this are the single wire diameter and the number of single wires. This means that we can achieve a nominal conductor cross-section (important for the current flow) with different combinations. It can be made of a single solid strand or consist of many small strands that ultimately have the same area in total.

The following classification is used:

Class 1: solid

Class 2: multi-wire

Class 5: finely stranded

Class 6: fine wire

These progressive classes were created to allow users to roughly categorise their flexibility. This is sufficient for simple movement applications.

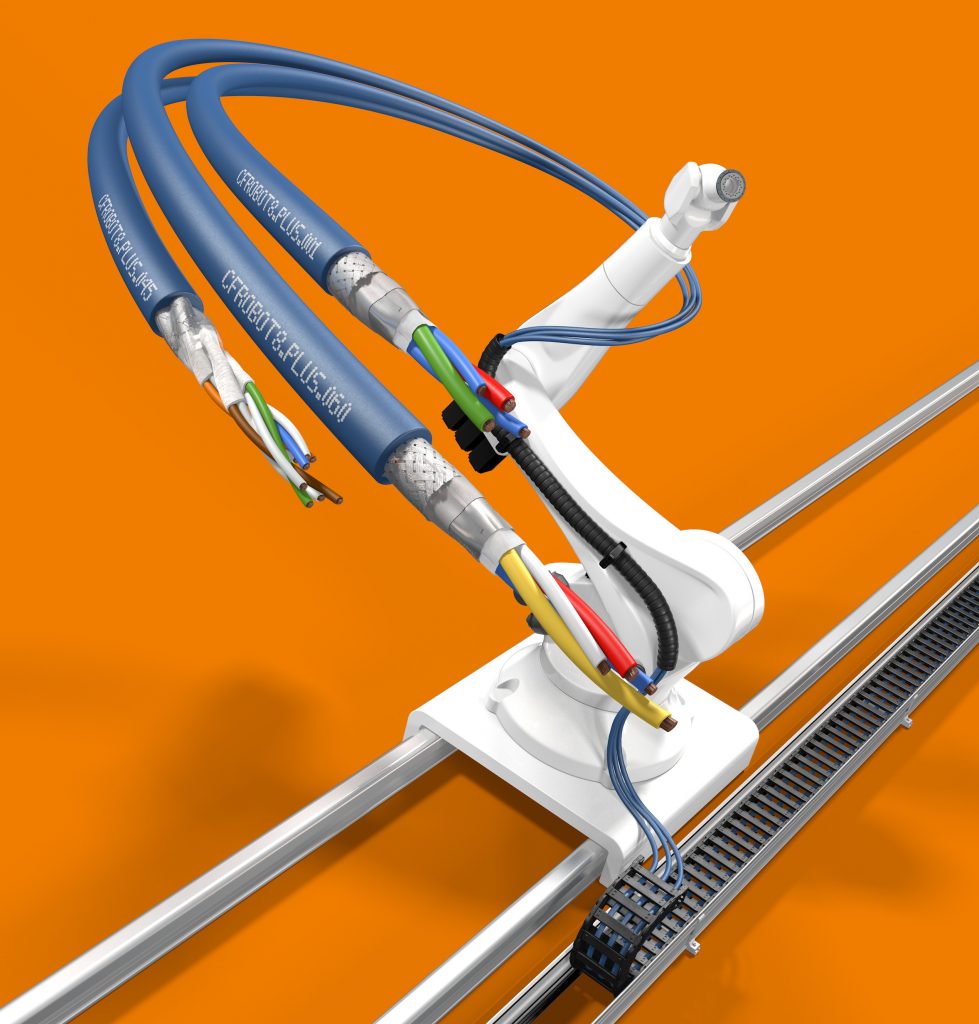

Best in class for continuously moving applications, energy chains or robots

For motion, it is obvious that it shouldn’t be a solid core, but it turns out that the strands shouldn’t be too fine either.

We have found in countless tests that the stranded wire must not be too fine either, since it is stretched by the tensile forces in the outer area of the wire when it is bent. If the bend is removed again, small wire loops can occur because copper does not contract again. As a result, the repetitive movement creates more and more of these wire loops. At some point the strand breaks. The optimal construction for movement is not the one with the thinnest strand, but the one where the strand thickness is matched to the respective nominal conductor overall cross-section (e.g. 0.5mm², 0.75mm², 1.0mm² or 1.5mm²).

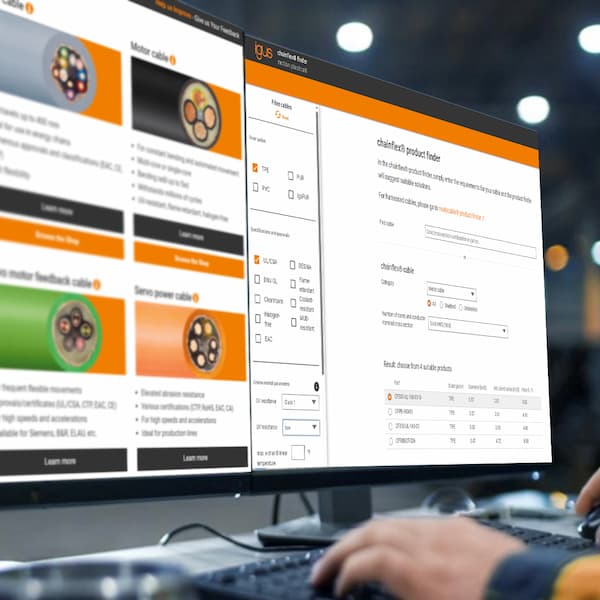

Since we use exactly the right strand for you in the core, you do not need to specify the conductor class with igus®. Tell us what your cable needs to achieve mechanically, and we will find the right product for you from the catalogue range. And you can use the chainflex® price check directly here:

Price check