To print or not to print…. that is the question…

“To print or not to print”, a question that may not resonate with many of us but as millions of people adapt to the new normality of life at home, people are having time to think. And this is no different for most igus® employees. Whilst working from home, one of the engineers has been trying to gain a greater understanding of 3D printing and the benefits of this method for producing parts and here are his findings.

Here is his story ” To print or not to print:

“I have recently acquired my own 3D printer. I found that I had become very interested in the growing industry of 3D printing. This newfound interest has really only been discovered since I started working at igus®. It has enabled me to get into the fast-moving world that is quick design and rapid prototyping.

I was introduced to the 3D print world through working with several of my customers on a wide range of projects. Whilst we cover most 3D print technologies at igus®, we tend to lean towards our SLS laser sintering service. This type of 3D printing provides strong, hard wearing and presentable parts quickly and at an economical price.

So, as mentioned above, having been introduced to this relatively new way of producing parts, it led me to buy my own 3D printer to enable me to gain a greater knowledge in the art of 3D printing. I started by using some simple black PLA FDM in order to print some parts for a friend who is building a home PC racing simulator.

These parts consist of a gear stick and an alignment bracket. These are designed to help the parts function better and to replicate the feeling as closely as possible to the real thing.

The parts have since been tested with great success. This made me think; could I use my printer and an igus® material like the FDM iglidur I150, to show my customers just what rapid prototyping can do for them?

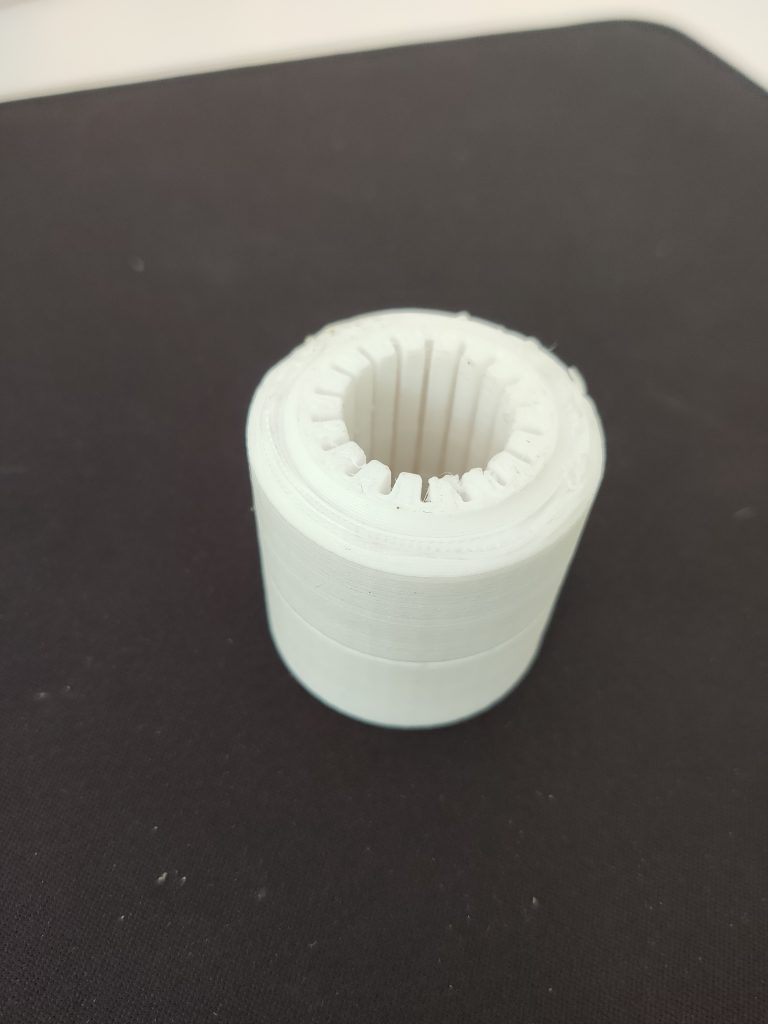

With this in mind, I thought about an application that a customer had mentioned to me previously, which needed customised round linear bearings. I suggested 3D printing to him as not only would this provide a capable wear material, but also a quick and efficient service that would lead to minimal downtime on their machines.

I decided to print the custom designed part for the customer, in the iglidur I150 material. The aim with the sample was to give them an idea of the materials that can be used, the great prices and the speed of manufacture. This sample, produced at home on my basic machine, led to an order and the customer had the parts made through igus®.

Whilst this is only a small glimpse into the exciting world of 3D printing, I believe it shows what can be done with not just the 3D technology, but also igus®’ capabilities when it comes to helping customers in a lean, cost- effective and efficient manner.”

So, in conclusion, the question ” to print or not to print” opens a lot of considerations and there are certainly benefits to 3D printing which we have discovered.

igus® has remained open throughout the corona-virus lockdown, supporting customers wherever necessary but this situation has clearly prevented some employees from doing their day to day roles. With a little initiative, some adaptability and the desire to continue helping from home, this goes to show the lengths that people are supporting industry in any way possible.

For more details on 3D printing please visit the igus® website.

To read more blogs relating to 3D printing click here.

Alternatively, please contact the Product Manager Dean Aylott: daylott@igus.co.uk