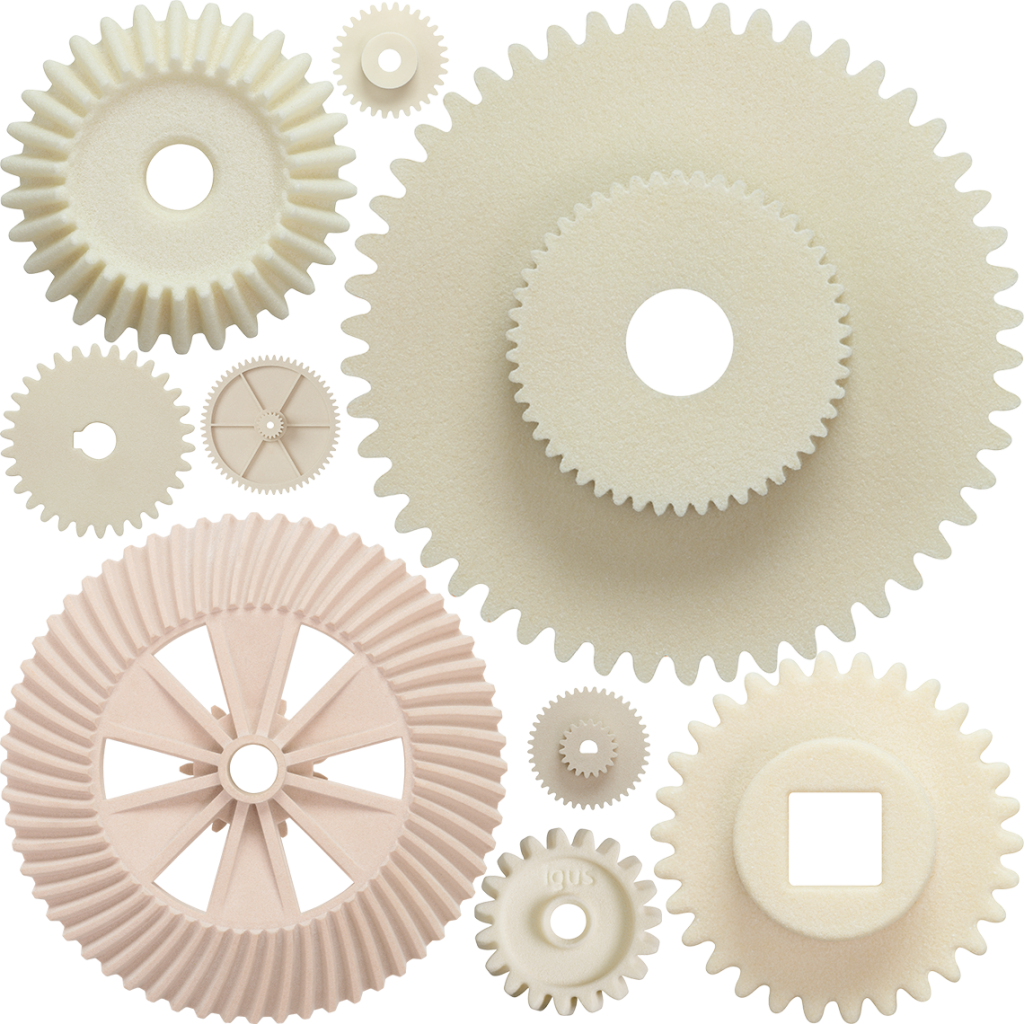

What are the main benefits of using polymer gears?

When considering the benefits of using polymer gears over conventional metal ones, there are key benefits that stick out: weight reduction, corrosion resistance and low cost. We are finding that more and more people are swapping out traditional bearings and gears for polymer ones, and we will look in more depth at the main reasons why.

The main benefits of using polymer gears

Weight reduction

Weight reduction is a huge benefit for many industries and companies. If we take Automotive, this extremely competitive industry strives for perfection and has stringent guidelines and goals. Weight reduction within a car can be one of them. A simple change from a heavy metal gear to a high-performance polymer gear can reduce weight by seven times.

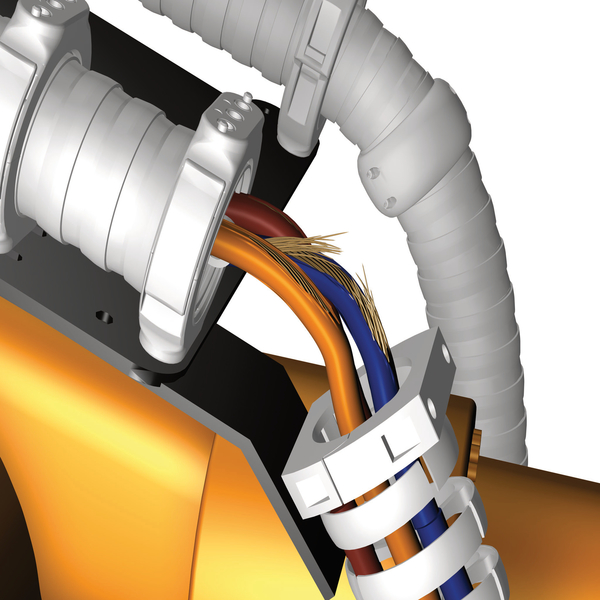

It is a similar story for the aerospace industry, ensuring they maintain the weight restrictions is imperative, and using a polymer gear in a gearbox instead of a heavy metal one is a quick and easy change to make. Not only does it help with weight reduction, it also has other benefits, such as less maintenance and a reduction in costs….

Non-corrosive

One of the best things about non-metallic parts is the reduction in corrosion. Polymer gears do not corrode, they do not rust and, depending on the material, they are chemically resistant. The range of igus® moulded gears allows a resilience against many chemicals. This is a huge advantage over metallic gears, saving not only time but money too. Knowing that the gears are not going to deteriorate within a machine or application is peace of mind to the manufacturer and end customer. This also ensures that these polymer gears can be used in applications where metallic gears would fail, giving designers more flexibility.

Cost-effective

igus® gears are now being moulded in high volume and in a standard range. Unlike 3D printed gears, which are ideal for smaller quantities such as prototypes, the moulded polymer gears are produced on a much larger scale, thousands of parts at a time. This allows the cost to be kept low. When comparing the cost of a metallic gear to a polymer gear, if the gear cost is low, generally the quality will be low. This is not the case with polymer gears.

As a plastics manufacturer, we know how to mass produce parts in high-performance polymers, ensuring high quality. We also offer a tool which allows you to calculate the service life of the gear by adding a few application parameters. Being able to plan a gear into a design, knowing how long that gear will last ensures you are getting the best for your application.

We also offer price breaks so the more you buy, the cheaper the piece price becomes.

In conclusion

The use of polymer gears in applications, such as actuators and gear boxes, is becoming more and more common and this can be attributed to: low maintenance, predictable life span, affordability, and also people are starting to understand the sustainability of polymer gears in comparison to traditional metal ones. The igus® polymer gears tick all these boxes. Thanks to the tribological polymers used, no lubrication is required, once again saving money and time, no lubrication means no or very little maintenance and no lubrication finding its way back into the environment.

There are obviously more than three benefits of using polymer gears but hopefully these three will be enough to convince you to try polymer gears instead of metal ones in your next application.

For more blogs on our range of polymer gears click here https://blog.igus.co.uk/?s=gears and if you have an application you want to try a polymer gear, please let us know.