What is a spur gear?

Gears can come in a variety of shapes, sizes, designs and materials: spur gear, helical gear to name a few. This ensures there is a gear for every application. There are a number of gear types that are similar in their design. Invariably there can be an overlap of gears within an application but this blog focuses on the spur gear.

What is a gear?

A gear is a toothed wheel where the teeth run round the circumference of the wheel at regular intervals. The main purpose of gears is to transmit motion between 2 shafts, gears are used to obtain different speeds, torques and direction of movement between shafts. The beauty of the gear design is the teeth, which prevent slippage ensuring a continued force is present.

When two or more gears mesh, they form a geartrain. Within the geartrain the gears that mesh creates a gear ratio, and this dictates how the motion of the drive shaft is modified to meet the needs of the application. The gear ratio is the relationship between the number of teeth on the driven gear versus the number of teeth on the driving gear and this tell us how many times each gear will rotate relative to each other.

When gears mesh the driven gear will always rotate in the opposite direction to the driver gear. When the driven gear is smaller than the driver, we will see that driven gear increases in speed but reduce’ s in torque compared to the driver gear. When the driven gear is larger than the driver gear, we see the opposite, torque up and speed down..

What is a spur gear?

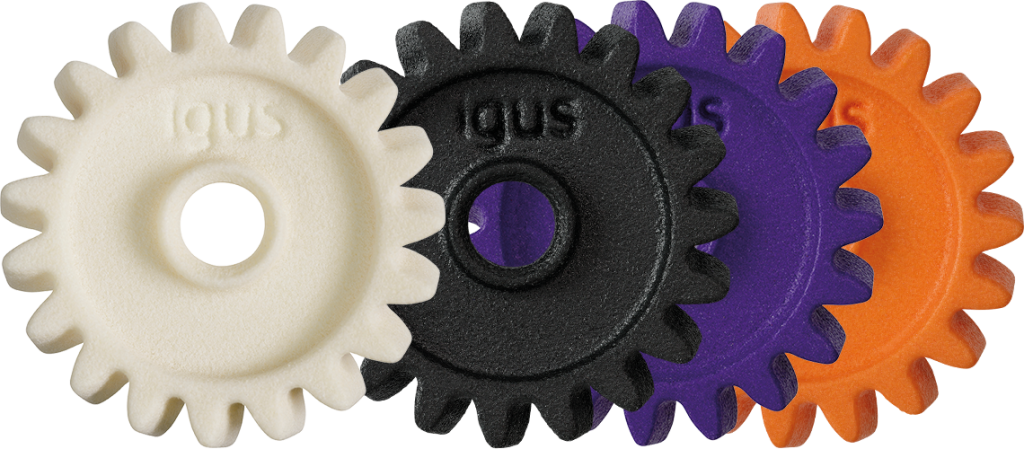

When considering the most common type of gear, the spur gear comes out on top. When describing the appearance of a gear, it would no doubt be a spur gear design you would describe. The main reason for this would be the simplicity of the design; the involute gear profile means that the teeth between a pair of gears come together at a single point, at this point the teeth are rolling on each other.

The design is purposely created like this to ensure that any gear that has the same pitch, pressure angle and helix angle will be able to operate together. The spur gear remains more cost-effective than other gears, such as helical gears. The simplicity of the spur gear design means that the manufacturing costs are low, and the manufacturing method is quick.

What applications would you use spur gears in?

There are a huge range of applications that spur gears are used in. In fact, there will be applications closer to you right now than you realise…. Applications such as clocks, washing and drying machines, power plant, materials handling systems, aerospace and aircrafts, railways and trains and medical devices.

The range of applications for these gears is vast and they need to be adaptable depending on the application environments.

For example, gear pumps, these are most commonly used in hydraulic power applications and applications handling potentially dangerous chemicals so these need to be manufactured from special materials.

What are the main materials that spur gears are made from?

Traditionally, spur gears are manufactured from metals such as brass or steel, but more recently, they are becoming conventional in nylon or polycarbonate. At igus® we 3D print a lot of bespoke gears and we also have a full range of standard igus® polymers to choose from. We have 8 different materials as standard and 300 dimensions available. Manufacturing in high-performance plastics ensures that the issues with noise at high-speeds are reduced.

What are the main differences between spur gears and helical gears?

There are quite a few differences between the two gears, however, the main difference is the potential applications that they are suitable for. The helical gears can be used in non-parallel shafts which is very different to the spur gears. The angled design of the teeth allows for perpendicular meshing of the gears, which opens up a larger range of potential applications, such as in conveyors and elevators, gearboxes for the automotive and printing industries and more.

For more blogs on gears click here or if need some assistance with an enquiry please contact us